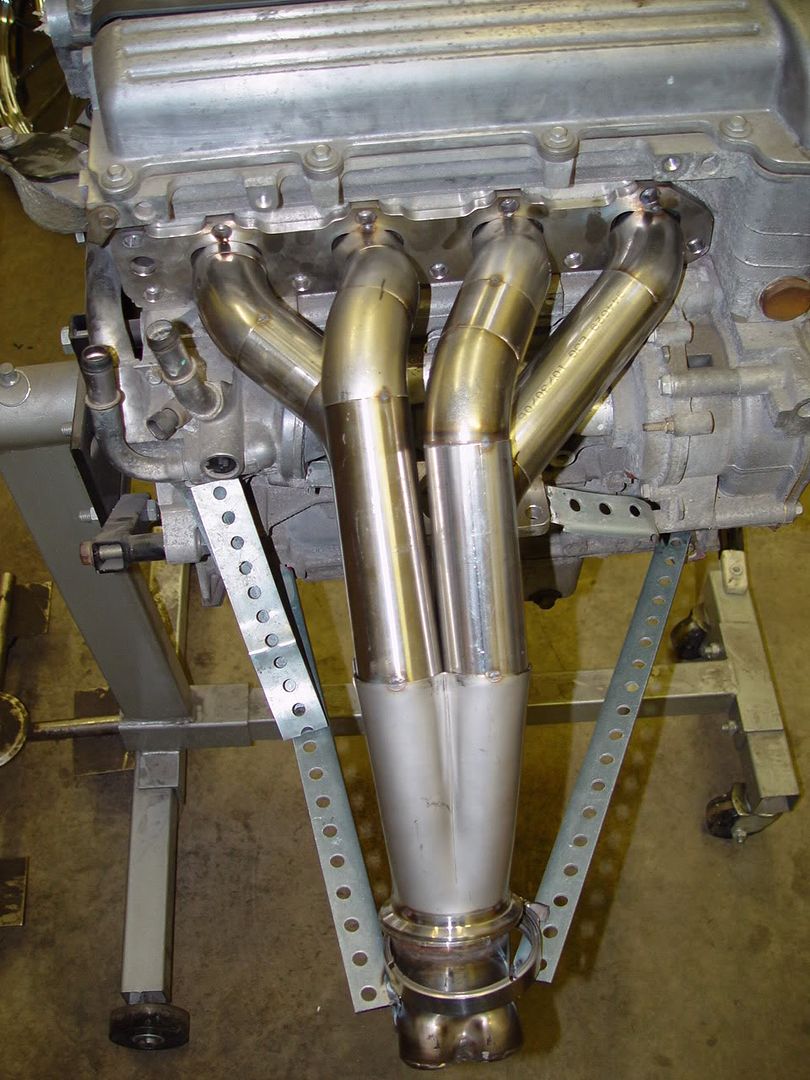

My friend that did the fabrication for my turbo setup just finished making a header for a Cobalt with the 2.2L Ecotec motor. Thought this may interest some. He specializes in custom intake, exhaust and f/i applications using T304 stainless.

Sorry for this pics being redic huge…

Looks pretty nice. Is the guy local?

I think he does good work.

16ga. T304 SS TIG/Perge welded…

Port Byron, NY 13140

Port to runner transitions need some work, as well as the collector, but for a budget header with a stamped merge it doesn’t look too bad.

I can tell you fop a fact though that it was not back purged…at least not very well at all.

It may not have been. He usually does, but I wasn’t there when he built this one…

Just pointing it out for you that’s all. You can see the oxide “sugaring” on the inside welds, especially in the collector.

Hey, edubs.

Do you know what does your friend’s header design base on in terms of calculations (header diameter, length and outlet sizing); and what kind of reference does he use for the such design and calculations? Does he know any good books on this subject besides “The Scientific Design of Exhaust and Intake Systems” by smith/morrison?

Thanks.

Nice work BTW OP.

You know I am new to the tig process and I love it BTW. But I havent taken the time to look into back purging yet. From what you just said, I assume it is shielding gas pumped inside the work, to keep the penetration inside the projects welds from contaminating? I noticed that when I was welding up my charge pipes for the jetta and the wastegate/exhaust work I did too. The welds outside were butter, but the inside was all dumpy looking.

please enlighten me, not to steal the thread.

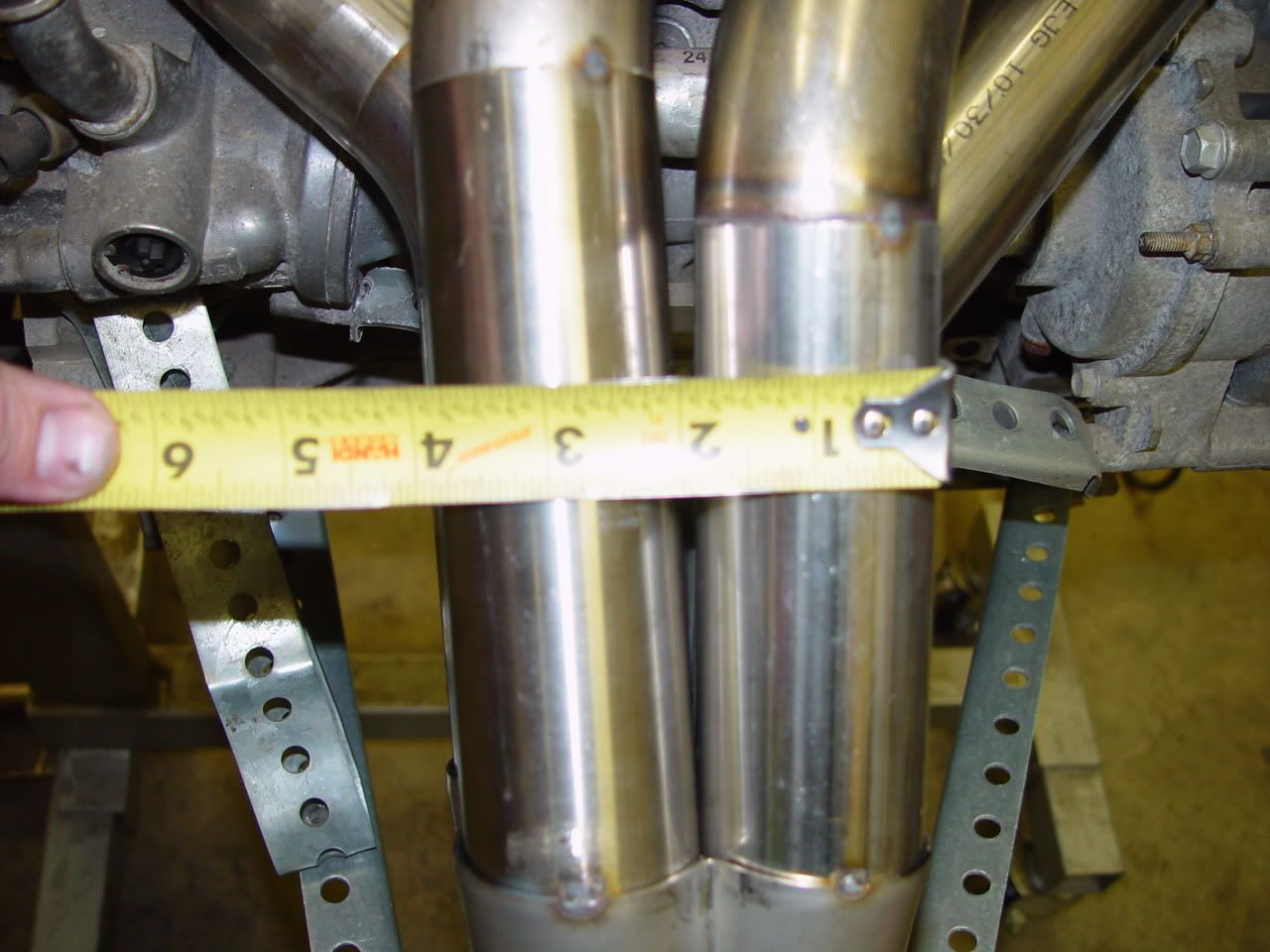

how big are the primaries, 1 7/8" ?

You were right. He forgot to turn on the gas when he was welding the primaries to the collector.

What would you use, as opposed to a stamped collector? From what I have heard, this collector is proven very reliable and efficient with the “star merge thing” (my technical description, lol).

I can ask him. I know he worked with one of the world leaders in fluid dynamics for quite a few years and learned a lot from him. He definitely takes many things into consideration when he builds these. This header is almost perfectly equal length, with the exception of primary #3 (iirc) because of the way it had to run to fit correctly.

Thanks!

No biggie on high-jacking the thread, boxer seems to have a good amount of knowledge of this stuff and that’s what we’re here for.

Dead on. 2" OD, 1-7/8" ID. Length is 14” and the collector is 6” long 2” prim to 3” DP…

Yeah I can tell it was not back purged too !! Cause my name is Clark Kent and I got X-ray vision too see the inside of the tubes !!! lol

I’m sure that post will get removed too !! Just like the last one !!! Bitches !!!

Been there before on the closed tank valve before :lol

Nothing really wrong with stamped collectors, they are just general pieces without any parameters really taken into account. A fabricated collector with a tuned spigot length, convergence angles, and a tuned mega phone are where you’ll make the power.

again though, not bad for a budget header ![]()

KrazyKid…backpurging is just as it sounds, purging the nitrogen/o2 from the primaries and filling with shielding gas(argon, helium, xenon, etc). If you cannot back purge the part you can use a flux(I like Solar Flux type B)

Most stuff like this I just put into my welding chamber and fill with argon or helium(for titanium) as it ensures a complete purge.

----> Adam(boxersix) on JVG's computer<----.

lol i got really scared that jvg actually knew this until i read it was adam

I pulled the picture of the inside of the collector because it not being back-purged was a mistake…

Gotchya, lol. Thanks for the input!

I was just being an ass either way and trying to rustle some feathers !!!:ohnoes

Didn’t really care either way yes I know i sound like an ass but I still don’t care!!!:hug

sweet stuff…im going to need a header made soon…the one on my geo is junk…it has very poor scavenging characteristics…but what would you expect from a pacesetter…and btw it was on the car when i bought it…so not my fault…lol

anyways…you know about how much this bad boy costs? (for reference/ballpark figures)

It would depend on what size primaries and collector you want. He only uses T304 for flange and all, so it definitely wouldn’t be cheap compared to those mild steel pieces. I could look into what his price would be for ya; though, on one that wasn’t just a first-build/test-piece…