anything is bigger than ur turbo’s

hey cristian, ive been looking into them autopower/safedrives and there fitments into the bmw seem to be less then great. Ive heard some good stuff about the tc kline bars and such.

However im thinking that in a project like this you should get something custom. After all the cutting and gutting you need to strengthin the chassis a little better then a autopower cage. just me thinking. If you do go with the autopower have the bolt plates replaced with larger ones and make sure its welded into place.

some of the guys have seen actual carshes at road coarses where the legs actual tear through the floor in event of a rollover do to the surface area being too small and not welded in. I believe that 2007 it needs to be welded in now too.

Their fitment is crap, and the harness bar is in the complete wrong location. Even after giving them proper measurements and them claiming they would weld one properly for a friend’s car, it was still wrong.

Any reason for not building your own? No bender?

just a pain in the ass… it’s a very time consuming process.

Whats this bitch gonna weigh when hopefully its completely assembled???

If your looking for something premade

VSR makes a better premade e30 4 point with the harness bar in the correction location rofl. You could weld it in and use it as a basis for a cage like you did with the STI.

last night’s progress…

Cut the rest of the tunnel out (another 1" from the rear) and was able to bolt up the transmission. It fits nicely, there is no need to remove or even move the engine to access the transmission bolts… That’s a great feature. Especially for anyone who has ever tried to change the transmission on a 300ZX…

I made a temporary tranny mount out of this prybar:

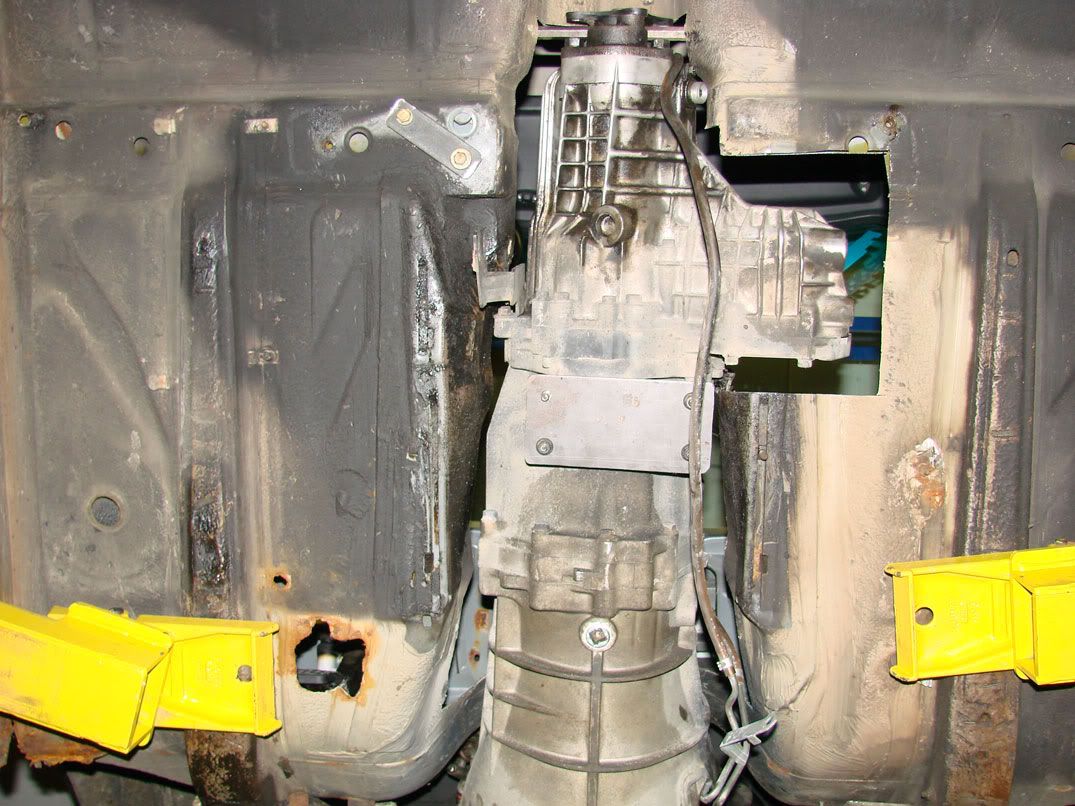

Here are a few shots of the trans in the car:

Next, I began planning a transmission mount. The first step was to make bolting plates. You can see the two i made here:

The main transmission bolting plate is made from 7GA Mild steel. You can see it bolted to the rubber transmission mount. We decided on keeping the stock rubber trans mount, despite the fact that we are using solid engine mounts. Need to have some compliance somewhere!

The other bolting plate picks up the two bolts for the stock transmission mount. Notice the distance from the rubber trans mount to the stock location. Since the transmission utilizes the rubber mount, simply joining the rubber mount to the stock location would result in a point loaded cantilever beam. The chassis is not meant to maintain such loading especially at a point that has already been compromised by tunnel modifications, so an alternate solution, or a dual cantilever beam must be incorporated.

As I mentioned a few days ago, since so much material was removed from the tunnel, a support brace would be desired. This brace was to be located midway down the tunnel, underneath the transmission.

Since the forward face of the rubber mount on the transmission is about midway back on the tunnel, it was decided that a transmission mount/chassis brace “subframe” could be constructed. Bolting plates will be welded to the chassis floor, then the “subframe” will be bolted to that.

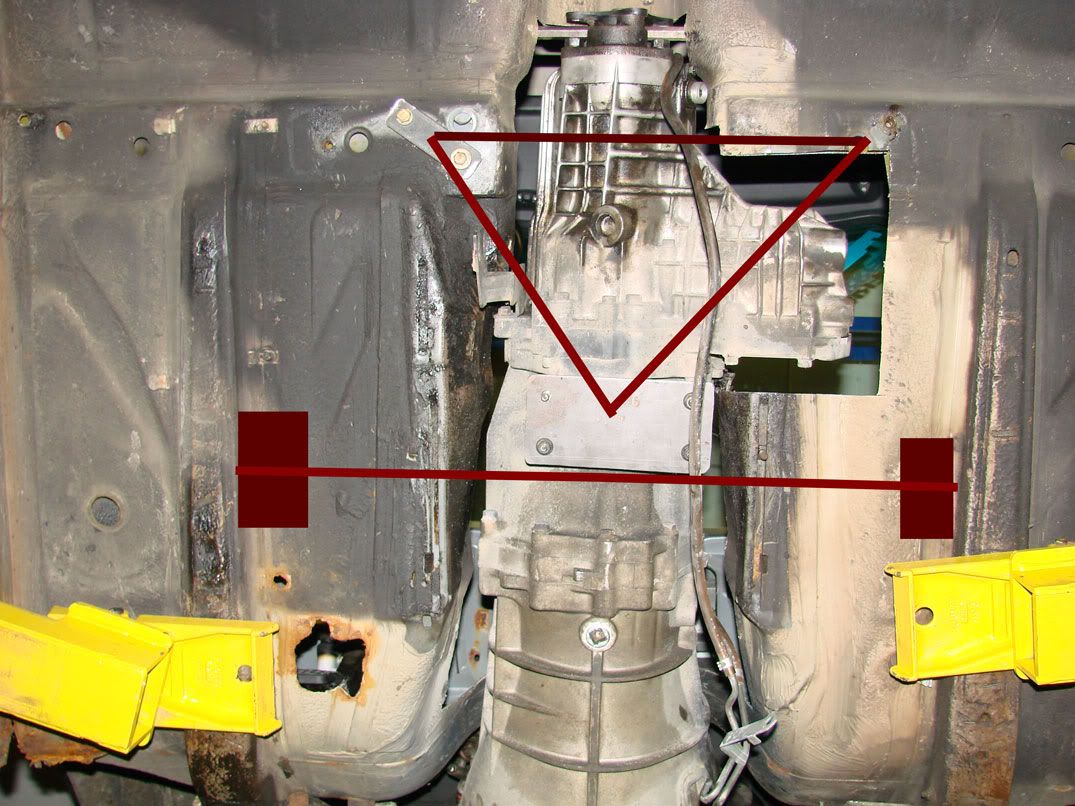

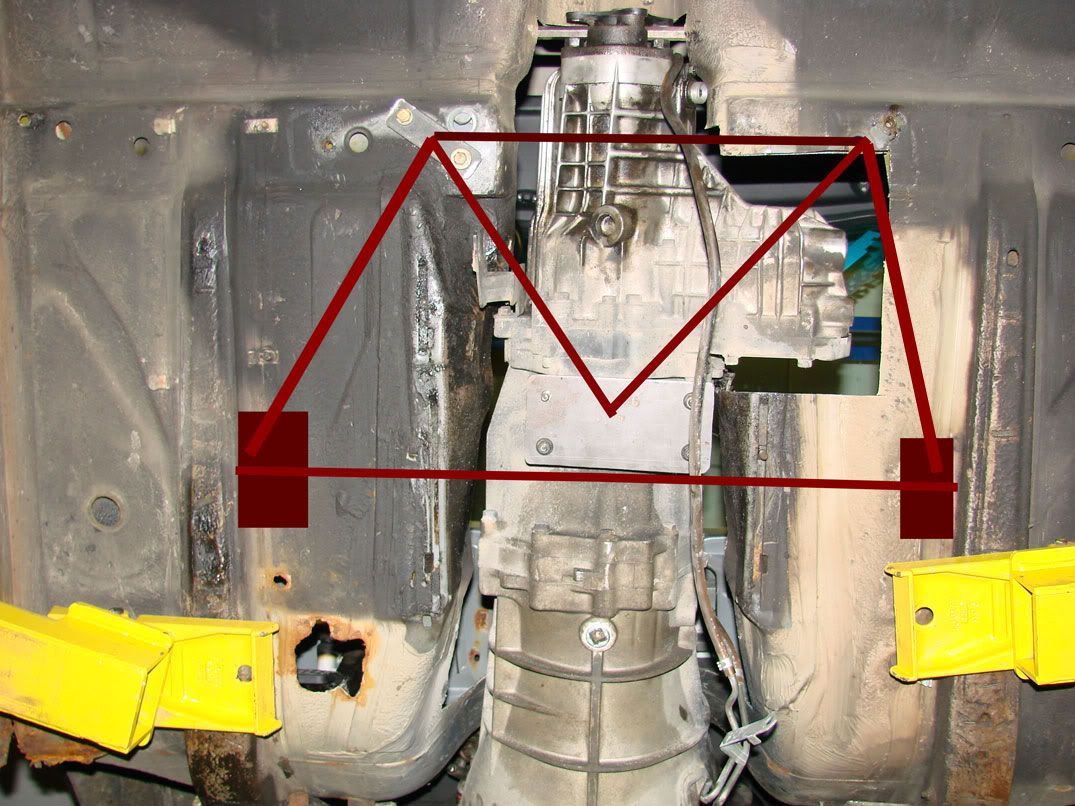

Here is an artist’s rendition of the proposed solution:

i fuggin like it

oh yeah, the subframe will be fabbed out of 1" x 1" x 11GA square tube.

you should have just done a BMW conversion to an escort like they did on pimp my ride

How much are you guys looking at the weight of this build?

about 500 rwhp.

2400lbs or less.

If this is what you mean, it’s a good one. A truss is VERY strong. Loaded at a joint, all members are in perfect tension or compression.

thats gonna be sick

this project fucking rocks. ide love to get in on sumn like this, but i would be no help

:tup: man, and keep this shit coming

can me and kevin716 paint this pig? pink? please?

Did carnut mean run the braces from lower left to upper right, lower right through upper left, centered through the bolt plate? Then you could run the outside trusses to reduce flex.

2400lbs / 500 bhp = 4.8lbs./hp. :eek: Ridiculous. :tup:

are you good? if so yes!

NO! It’s going to be green… or the lagunaseca blue that everyone humps… But i think a super deep olive green w/ NO flake would be tit’s… On bronze wheels with a bronze or brown cage…

perhaps, but i prefer the method i drew. It’s overkill no matter what.

wow man this car is nucking futs