I have a small sheet of 1/2" 304 ss (18x36) that ill be sending out to have a set of flanges cut from, but it seams that the people that were originally interested no longer are.

I would like to divvy up the entire sheet and be done with it.

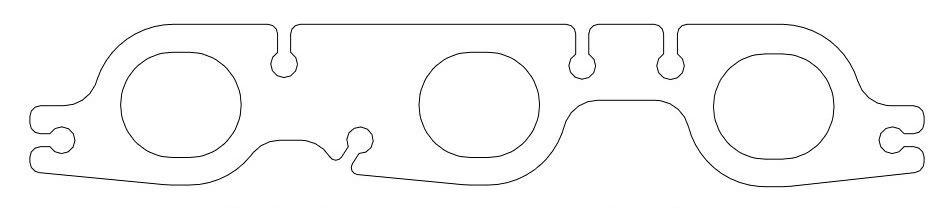

Price i currently have is $50/each for the flange below if i have 9 cut. 18 of said example flanges actually fit on the sheet.

If you want a specific flange but dont have a cad file i can do the cad work if you drop off a gasket / manifold / head.

No charge for the cad work if all you want is the flange in the end.

Holes are linked to the outside edge in this because cutting individual holes takes more work / adds a bunch of time, which means it would cost more, esp considering hole diameter is less then plate thickness

so are you trying to get the “group” to go in on flanges cuz you want to bring down your cost? or are you just offering the site? May I ask who is doing your cutting? You can PM me if you like…I have some competitive pricing available

All im getting out of this deal is the $ i spent on the material, I dont need any flanges myself as my project is getting parted / scrapped. One set of flanges is spoken for by somedude for his SHOmaro project. Would be nice if it didn’t cost $200 to have that one set cut.

As for the shop thats doing the cutting, i have a few i work with already, and i typically prefer to keep their info to myself. Ive seen enough people / companies try to snipe work / info that ive learned its best to just stay quite, even on the smallest of jobs.

I agree with the quiet…I just have some friends with machines that work cheap…whats your per hr rate on the person you have?

What do you want for the left over material?

Hourly rate, donno. sinse i cant estimate the time on stuff like this anyways. wouldnt do me any good.

Im hoping that there is no left over material on this, but i also though that i could find 9 people that wanted a pair of flanges, but apparently not.

Cmon people, i may very well soon have a 1.21 gigawatt laser cutter and a full machine shop at my disposal,

test piece for the order made some adjustments and the final pieces will be here today or tomorrow

bolt holes were set to .400 for .388 studs and it slips right on if you hold it straight enough, final design is set for .480" though