Well, a bit of an update. Sorry for the slight redundancy, but I wrote up an extensive post for the v8rx7forum swap board and thought it’d be nice to share and incorporate an update with!

I remember I spent a decent bit of time looking for exhaust photos and information, so I thought I’d post up a quick rundown of what I ended up doing, in case it helps anyone else decide on their build.

If I had to do it again, I probably would have reduced to 2.5" sooner, since my power goals are mild and there were major clearance issues on the drivers side (unless you wanted to lose a lot of ground clearance).

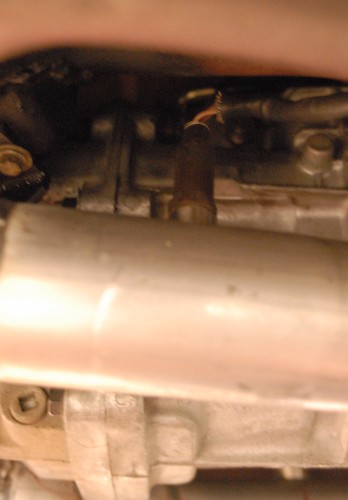

I also took this chance to fix one of my #1 issues with the swap, which is the terrible fitment of the O2 sensors with JTR headers. I’m guessing JTR has long since fixed the issue, but some of my parts are quite old. Anyway, my driver’s O2 needed at least .5" ground out of one of the webbed fins of the transmission and the passenger’s one was hitting as well, but no material was removed to make it fit.

My solution (suggested by my friend doing the fab work on this) was to copy the C5 corvette style o2 placement and have them straight up from the exhaust.

Here’s a crappy photo of it. I’ll get more when the exhaust is out and they’re fully welded on. This was just a quick mock-up using a junk sensor. Passenger’s side, maybe 4" back from the exhaust flange to the header.

We found plenty of room to run them straight up and this will also allow for much nicer wiring, since it can just follow the trans harness up into the engine bay, no sagging wires or anything to catch debris.

I’m running the 13111 Bosch O2s that are for the rear O2 sensors of a C5 Corvette. It’s a common mod for F-bodies with headers, since they have a 24"+ pigtail, if I remember right. Tons of wire length to allow proper routing. Maybe too much, but we’ll see.

So with that out of the way, I’ll start with the end. Here’s basically the final product. We still need to add hangers and finish fully welding the new o2 bungs.

The mufflers are 2 Magnaflow 2.5" with a 4" outer case. Part number is available if you want it, but they’re just the regular straight through Magnaflows from Summit. Only polished were in stock, so that’s what I ended up with. Length is 26", if my memory serves me. You wouldn’t want to go much longer or else you’d end up with a very tight bend after going under the rear subframe.

The pipe is regular aluminized steel, also from Summit. I’ll be coating it with some high temp paint (VHT actually works and doesn’t come off). The paint has held up on friend’s cars for a few years with no issues, so it should be a semi-long-term solution for cheap.

Diameter begins at 3" from the header outlet, does some twists to get around the driver’s side mount and transmission case and goes into a 3" homemade x-pipe.

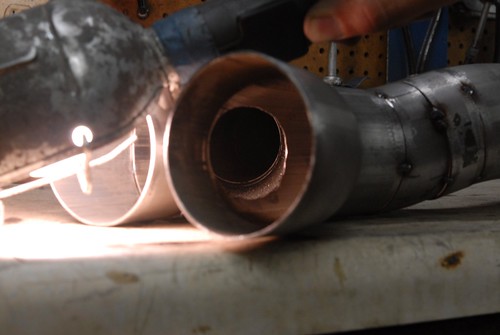

John’s x-pipe (internal view)

It’s worth noting here that we had to grind off a small portion of the trans case and some of the trans mount as well (Hinson mount). John rewelded the mount and reinforced it as well, but if you’re looking to undertake this, be aware! It would have been avoidable, but we’d be giving up at least 1-2" of ground clearance at that spot. It would likely have been the lowest point in the car then. Not something we wanted.

Back to diameter, we stepped it down to 2.5" after the X, since 3" dual is total overkill for anyone under like 600-700whp.

We were very unhappy with the cheap crap reducers I got from Summit, so John convinced me that we could make our own. Our methods were ghetto as hell, but the final product was awesome. They came out great and will flow better than probably anything short of some $200 Burns fancy thing.

Started by measuring the circumference of a 2.5" pipe and then marking that onto a 3" pipe. Then we decided how long the reducer could be and notched out the pipe. Tacked the narrow end to keep it from moving and moved on to the wormgear.

Drew it in just about all the way, until it made a nice transition into a regular 2.5" pipe and tacked it again. Fully welded it later on.

So, that’s the basics of what we did. All the bends are mandrel bends, a few are ever-so-slightly cheated with an angle on the end of a joint, but I’d challenge anyone to be able to pick out which ones and where. I’m amazed at how straight the system is. The sharpest bend is probably roughly 35-45*. It all fits well, everything except the spot between the transmission and mount on the driver’s side has plenty of clearance any nothing should hit. Stock hangers are being used with no additions. We still need to make some tips that look nice, finish the rear hangers and fine-tune the fitment. Obviously things will change and settle once I start driving, but any issues that might bring should be easily solved with tweaking the hangers or a hammer.

Sorry for rambling on, but I like to give a full view of what was done.