this for $1250:

or this for slightly less:

Looks pretty close. Fins are a little bit better in the first one though.

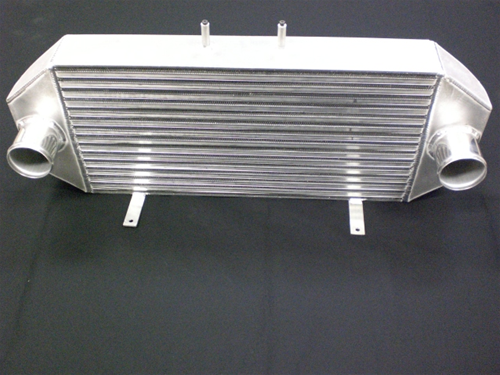

This one:

I’m guessing the second one is the one you just finished?

That’s a lot of monies for a FMIC. Mine was some ghetto XSPower that cost me $125 or so.

Bwaaaahaaaahaa +1 rep

Second one is also a used core. Ask me how I know ![]()

Sweet…:ahh

:lol

yeah thats a lot of money for just a fmic. What are your plans with the car?

it’ll be close to 400hp on E85 this year. The idea for this “winter’s” build was to improve its efficiency so I can make more power at lower boost and less heat.

So Mike, what did that intercooler cost you to have made?

So Mike, what did that intercooler cost you to have made?

Do you want a line of Honda boys at your shop or should I say it cost me $1200 and I get a cut from the people that still want you to make them one? LOL :rofl

:rofl Ohes Noes! No fanbois!

The latter idea works for me :lol

I would say neither.

What is an inter cooler anyway? that should be your first question to yourself. An inter cooler is a heat exchanger, a device who’s science is based on fluid mechanics, and heat transfer.

Ideally you would want the intercooler to shed as much heat as possible, and via math I will not make your head explode with, the intake charge will approach ambient under ideal conditions.

What makes a core superior to another is two things.

Turbulators

Pressure drop.

Turbulators are the fins INSIDE the intercooler. they create intentional turbulence. This makes sure that all of the charge air is tumbling so that it can make contact with the walls of the intercooler. If there were no turbulators, the air on the walls would remain there, and the air flowing thru the center would shed very little heat making the IC useless. Turbulence is critical.

Pressure drop: the turbulators cause high shear stress in the fluid, so it does take some energy to push that thru the turbulent core. With a given cross sectional area, more turbulence causes better cooling, but causes a higher pressure drop. Therefore with dense turbulators you will need a slightly bigger core for the same pressure drop as a “cheapo” core, but your delta-T will be much higher. This is a good thing.

If i were you, I would spend my money on a high quality core, from Garrett, or Bell, or Precision. Im not sure about what is going on inside the precision, but it looks to be an engineered product.

A good rule of thumb: If the fins on the outside look like they have crappy manufacturing quality, so do the fins on the inside. Your core #1 looks to be of much higher quality than your core #2.

And neither endtank design looks very good.

Good luck!

2nd one doesn’t look like a bar and plate deal…

Wasnt needed lmao!!!

Fuckin hooligan!

Let me clarify two points here:

The core utilized in the second picture was used, it was his original core. Hence it’s not going to be pretty, and it’s not a bar and plate. Decision made so on his part to reduce cost.

Endtanks are made as per his critical dimensions for his chassis while doing everything possible within said max dimensional parameters to maintain flow transition, all the while at the same time keeping costs low(IE no custom casted endtanks)

This thread was never about making a choice but rather a comparison of a typical universal IC that people manufacture for this application VS what what fabricated to fit his application now as he saw fit. If Mike had copious amounts of funding I would have CNC’ed billet dies, blanked some copper tanks, and brazed them to a Secan(Vendome) core. Just a guess but I’ll take a stab and say Mike probably doesn’t have $10K to throw at an intercooler.

Precision uses the Garrett cores and casted endtanks for their intercoolers. Pretty much the best cores without getting into the uber expensive aerospace stuff(like Vendome)

I agree 100%.

1320-20V my question for you is if the goal is turbulent flow in the intercooler how critical are good flowing end tanks?

PS: Casted isn’t a word.

Garrett core all day long. bar and plate, high FPI count.

and for heat exchangers/turbines on my aircraft, they were all Garrett-Honeywell, imagine that.

People rarely have a choice about end tanks. Generally space is an issue and dictates end tank design. All you want in an endtank is even pressure over the end of the core. This should be thought of in the negative direction. Dont visualize your endtank flow as pushing the air through the core, think of the core as a drain, and you need to distribute the air evenly to the drain.

The only time the endtank is a significant detriment is when flow velocity is high, and the cross sectional area is small between the tank and the core.

Flow distribution in the core is a function of shear stress in the endtank. Since the viscocity of air is extremely low, you need a pretty shitty endtank design before it becomes a serious detriment.

Basically you want some room for the air to move around, so that the velocity in the endtank is not excessive.

Velocity is the enemy of an intercooler, both in the core and in the endtank. This is a function of specific heat, which once again I will not bore you with.