Hey guys,

Not sure if anyone will be interested at all but I’m procrastinating like crazy right now trying to study for a midterm so I figure I’d start one of these build threads up here and try to update things as much as I can when I get time to share this build with you guys. I hope to some day do something similar for a 240 once I’m out of school.

Here’s a quick background summary of what this car’s all about:

- SAE sanctioned engineering collegiate design series competition called Baja SAE

- Schools compete internationally in North America, as well as other places in the world

- Baja SAE is the off-road racing buggy, Formula SAE is the formula-style race car

I’m in my last year at Waterloo mechanical engineering and I’ll be leading the overall build this year. Sold my 240 coupe last month so I can save some more $$ and also guarantee that I’ll spend more time on Baja. As part of my thesis project I’m specifically designing the chassis. There are 12 other 4th year designers on the team this year and we each design a subsystem and order material/parts before Christmas and begin building in the new year.

Some general rules:

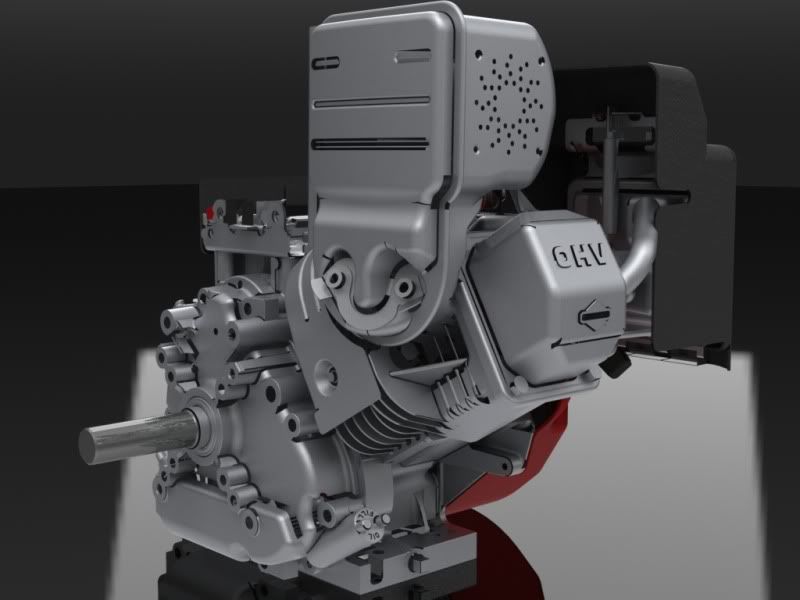

- Every team is restricted to using a Briggs & Stratton Intek Model 20 300cc engine that puts out 10hp (I know, mad weak…)

- No engine mods allowed (this comp is designed for suspension / chassis durability whereas Formula guys focus a lot of engine tuning)

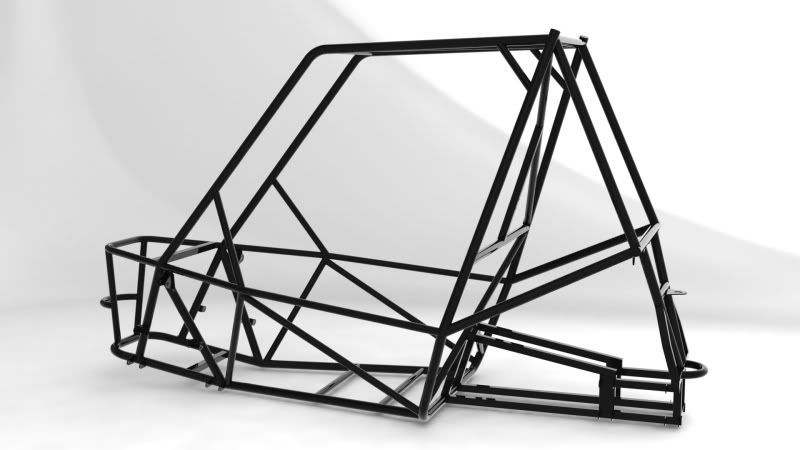

- Roll cage geometry and material selection is limited / constrained

- Various safety requirements (including the ability to exit the car under 5 seconds with all safety gear in use)

Some facts about our competition this year:

- Hosted by the Caterpillar Corporation at their development center in Peoria, Illinois (ie. big ass construction / obstacle site)

- Specialty event at this competition is the rock crawl

- Other dynamic events include acceleration, hill climb, and land maneuverability

- Events ends with a 4 hour endurance race (ranked by most laps completed)

- Endurance race is most important since counts for 400 / 1000 points for the whole competition

Here’s a quick summary of last year’s rock crawl competition to give you an idea of some of the dynamic events:

And here’s our model and car from last year:

Passed tech inspection and ready to rock:

^^Note that last year’s car had a floatation system because the car was required to fully float and maneuver in water! Belly structure at the bottom was packed with foam as well as areas in the front and rear. Rear fenders are shaped to act as a propulsion mechanism and front wheels effectively act as paddles for steering in the water.

And here we are in the water maneuverability event:

Brutal hill climb last year:

Car killer obstacle course (this particular section was very entertaining watching other teams get stuck and drivers smacking their heads against their steering wheels from the hard impact from the first log):

I hope to be doing a lot of this in our car this year!

Basic Specs:

- 300cc 10hp glorified lawn mower engine - limiter regulated at 3800 rpm

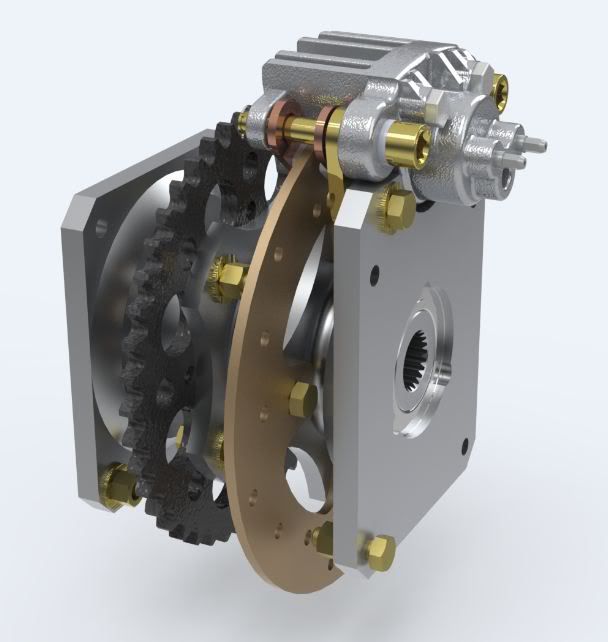

- CVT (ranges from 4.22:1 to 0.75:1) - engine always at full throttle @ 3800 rpm and CVT auto-adjusts depending on load

- 2 stage chain reduction to final drive assembly

- Polaris half shafts

- FR & RR Double wishbone SLA setup

- Polaris front hubs and brakes

- 2 Wilwood 5/8" BMCs with balance bar

- Fox Racing Float shocks

Model of the engine we’re provided with:

From concept: Final drive assembly model

To the final product: Final drive assembly

Frame (1020 CDS tubing, TIG’d) model

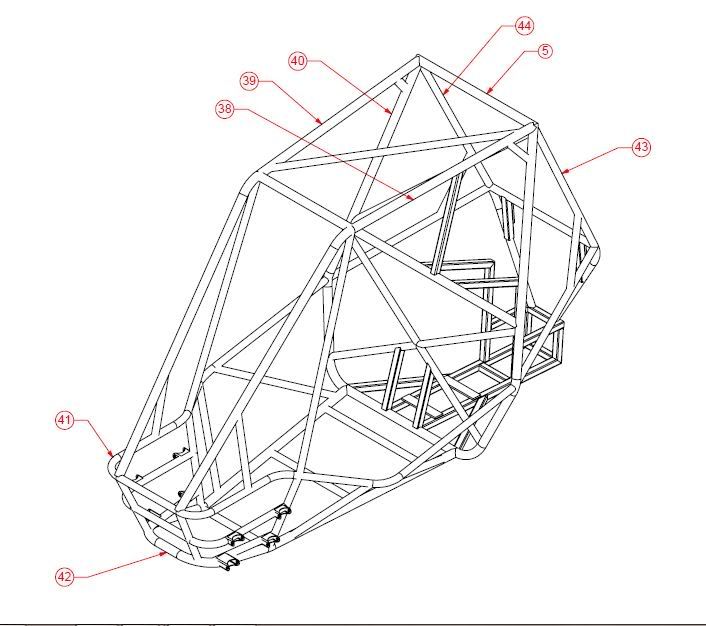

Drivetrain model

(almost) Completed 2010 model:

And here’s the all new 2011 model for this year! Still got lots of work left to do but the model finally got on the “ground” last weekend as we just finished the preliminary suspension modelling. Some things left are finishing up steering, brakes/throttle assembly, and the rear anti-roll bar.

Some big changes for this year:

- We’re going with a military / camo (maybe urban) theme this year since we have a sales presentation to prepare to market the vehicle as a saleable unit

- Engine now relocated to bottom of the frame and chain reductions are routed on top and behind to shorten wheelbase

- Front nose eliminated and extra front brace member added for better rollover impact resistance

- Hybrid frame will be a mix of 1020 DOM and 4130N (chromoly) DOM tubing to try and cut the weight down more

- Floor mounted pedal assembly setup

- Carbon seat fabrication from scratch

- Front steer relocation (traditionally used rear steer location on front uprights)

- Suspension a-arms will now be 4130N and rear arms will have camber adjustability, fronts will have caster adjustability

- Rear camber design target is 3 deg static and dynamic, front target is 3 deg static and around 4ish dynamic

- Target to reduce roll center and bump steer and design for a bit of positive Ackerman steer

Ok back to studying. Sorry for the long read. Hopefully for those that are interested this gives you enough details of what’s going on. I will update when I get more time. Frame build will start in December. We’re all ordering parts and going through Finite Element Analysis to try to lighten up certain components and finalize our model.

If you guys have any questions feel free to ask. Comments/critiques are welcome too!

---------- Post added at 11:24 PM ---------- Previous post was at 11:19 PM ----------

Oh and I forgot to mention but I’m going to insert the shameless plug here and say:

If anyone knows someone or would like to personally help out my team with charitable donations or potential sponsorship please do not hesitate to contact me. We’re always looking for support and this year we’d ideally like to try to buy a whole new set of Fox Float Evols instead of just saving up to buy 2. We usually need to raise about 20g’s and right now we’re around halfwayish.

Any help would be much appreciated. If you submit a charitable donation we provide you with a tax receipt that gets you half of it back basically.

Thanks!