I know this is more common and there is after market bolt on kits for other car. But the fwd GM grocery getters aren’t one.

DIY I did this last winter on my gtp,I just got my camera. lol And they worked great all this year. Better then I hoped, solving all the issues I wanted. (but no wheels up:cry:)

I was finding more power. And it was really showing up, how the car wasn’t set for it under heavy acceleration. I took some weight out of the car, and was running better tires also. The normal bad torque steer, but heavy front to back weight transverse I was getting on nittos and ETstreets. I was feeling unsafe controlling it, under 70-90. Slight turns, bumps, different pavement preps. Felt like you were trying to steer a crashing plane. The contraol arms deflect foreword, just from suspension design dealing with heavy loads. And the large contraol arms have poor large soft rubber bushings. With pockets, for even more deflection (softer ride for gradma). On the dyno I could really notice the control arm movement, and the whole wheel moving forward in the wheel well a few inches. And the CV boots would pull off the tripod. Huge PITA mess, and rebuilding them. The clamps were fine, its that the front rises so much. And the control arm movement would be more then the boots bellows could cover spinning in a angle. I didn’t want to make different control arms with solid rod ends. Or lower the car with stiffer suspension, that would help. I wanted to keep the soft stock ride:baby: I already changed my stock lower oil filled motor/trans mounts, witch helped. (DIY 3m window weld filled) polly uppers. I figured out what I needed and order parts form Speedwaymotors.com Witch is a great store I didnt know about.

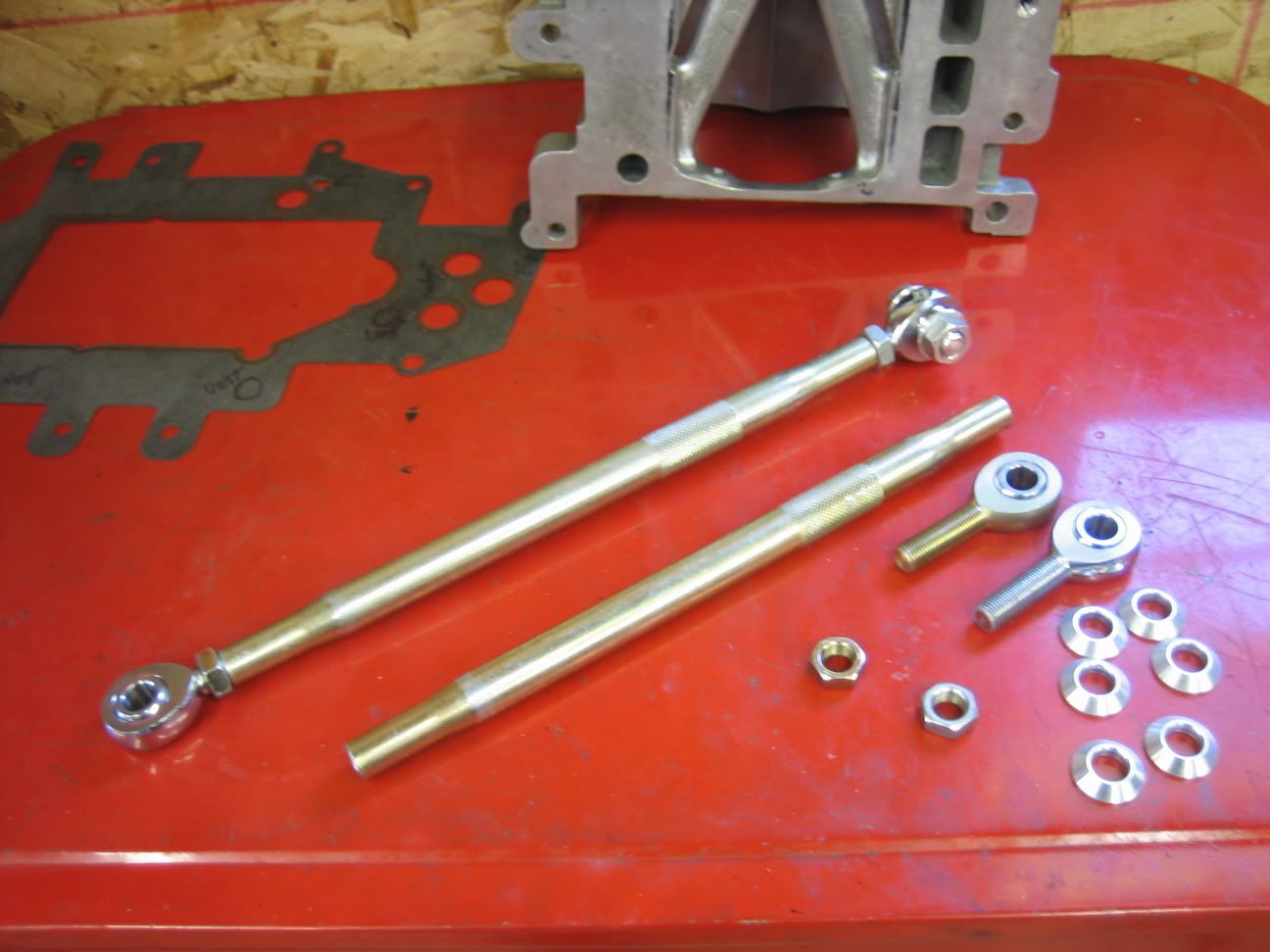

Precision rod ends (w/ Teflon Kevlar race)

1/2 threads 1/2 hole 2 LH 2 HR Like 8.95 each

http://www.speedwaymotors.com/xq/aspx/parent_id.105/dept_id.107/qx/DisplayGroup.htm

Sweded Steel raduis rods ( I thought about going Alum for weight but these are thin walled and very light. the Alum looks soild porbally same weight, and threads will be alot weaker)

2 12inch long, comes with tapped ends one side right on left. There was somthing like $10 each

http://www.speedwaymotors.com/xq/aspx/parent_id.105/dept_id.108/qx/DisplayGroup.htm

orderd a set of 1/2 alum conspacers came with 8. I forgot there price?

I got the jam nuts locally at John Deer tractor for 40 cents each. Over the $3.99 each online

Next door to Newera is Metal Surplus. Got some scape stock to make the brackets. ~$10?

1080 CRS, and 6061 because I went to the 6061 alum Wbody subframe the 00+ impalla/monteSS 04+GP have. To save weight over the 97-03 gp steel one. BrentStrong home town junkyard hookup, $40 I think? Shit barly fit in the back of neonGLH but it did.

made some cardboard templates

cut everything by hand. no mill in my garage:(

Got all the piece prepped. fit great on car mock up. rear mount was as far back a possibly. Bolt was gonna be close to fitting between the firewall.

Came close to trying to push alum wire in my mig. :smash2: Glad I didn’ t . Wanted it nice. So I had a friend Tig it

came out so nice.

subframe was pre heated, and I bushed it down with a stainless brush.

Used, so had some oil, and crap in the corners. And open spots form GM and the mounts, So it got a little dirty, I should have tried to get acid in there to clean it out better.

I also have all the 4 corner mounts fully welded. A gp drag car broke them and ran over the subframe motor/trans at the 60’. And there a few recalls on the early 99-00s that often crack. This one is etched june? 01 :tup:

Test fit it on and off the car about 4-5 times with the rack, everything on. For cleanrces.

Control arm brackets. Hand drill, cutoff wheel, fit great. Lots of weld area. I used my mig

Didn’t really loose any ground clearance. Wheels clear at full lock. Made a quick disconnect pin, to just reach under and unhook them. Once the cars on jackstands or a 2post you can’t get them out. It dose make some pump steer in the suspension, you’d think on paper. But I haven’t noticed feeling any driving all summer, with them on or off. Hyway dips I think sense both wheels should be changing toe the same amount/time it doesn’t make any and noticeable steering changing in such a slow, boaty car as is. Car pulls alot straiter and smother. No CV boot axle problems. Good stocks axles, I got a take off 25mile set off a 05 gt gp. I hammered on them with some 26x10.5 ETdrags getting low 1.7s too. Put a few thousand street miles, only had to put some preload form zero. To get rid of a slight vibration while turning and more then normal acceleration form under 5mph.