Not sure how much value this will provide but I have recieved quite a few PMs about basic electronic repairs. Well here is one I did for Joe (91MR2) for the Sony Deck in his Lotus. The backlighting for the LCD display was shot.

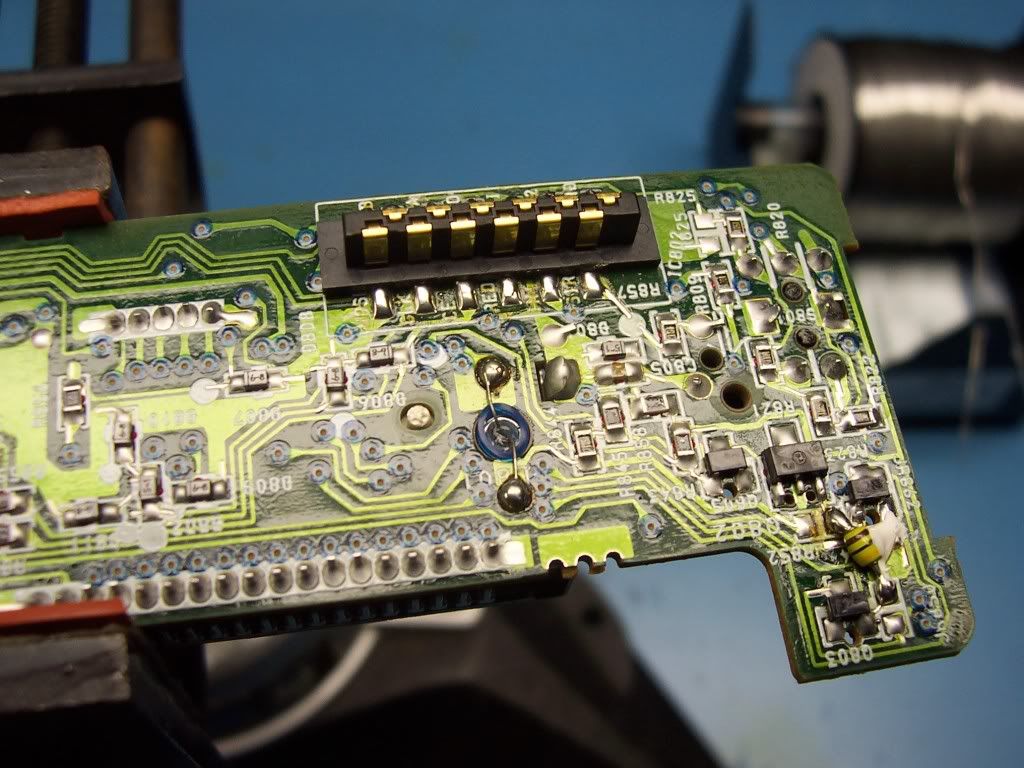

Here is the Sony Faceplate. He was lucky that everything is contained in here. That made this VERY easy.

Open the Faceplate to gain access to the troubled parts. Some of the electronics are not made to come apart. Take your time getting them open. Be ready for flying stuff such as buttons and springs.

Here is one of the two bulbs that needed to be replaced.

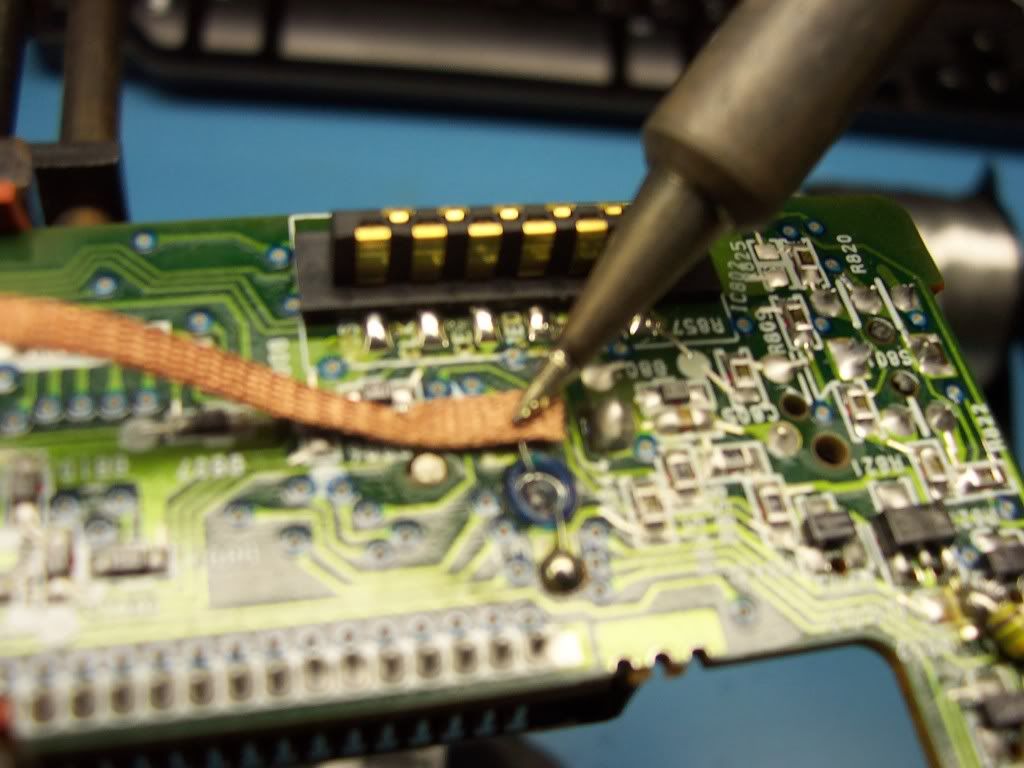

At this step most people would stop. I say continue. This is easy shit. Using solder wick/tape and some flux you can easily remove the joint. Apply flux to the tape and the joint.

Then, apply heat.

---------- Post added at 04:37 PM ---------- Previous post was at 04:37 PM ----------

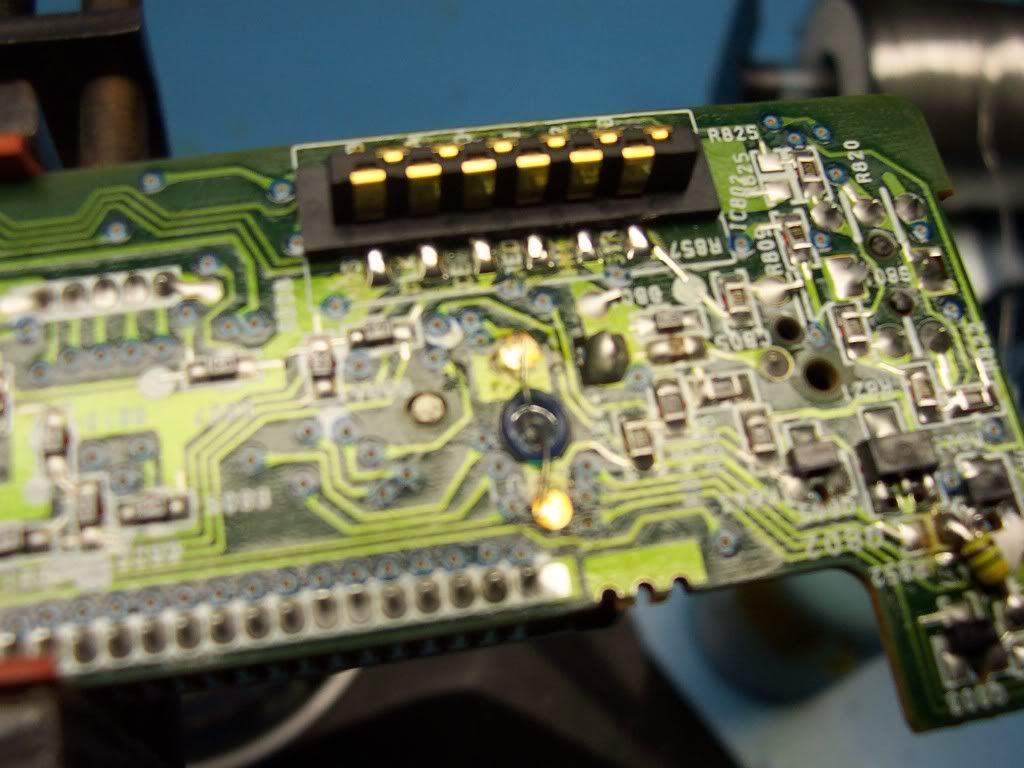

The idea is to saturate the solder wick with the molten solder. Leaving a nice clean pad.

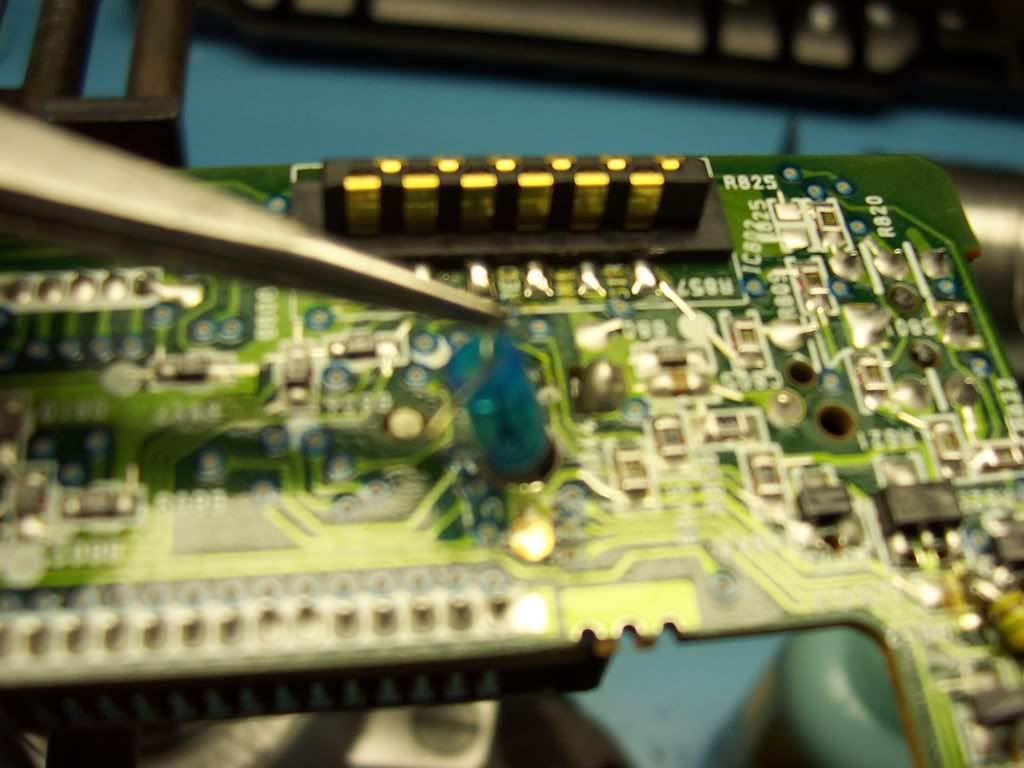

Remove the bulb.

Swap the OEM cover over to the new bulb.

For this project the new bulb I sourced from www.digikey.com which has pretty much everything you need component wise.

Solder in the new bulb and reassemble. Done.