??

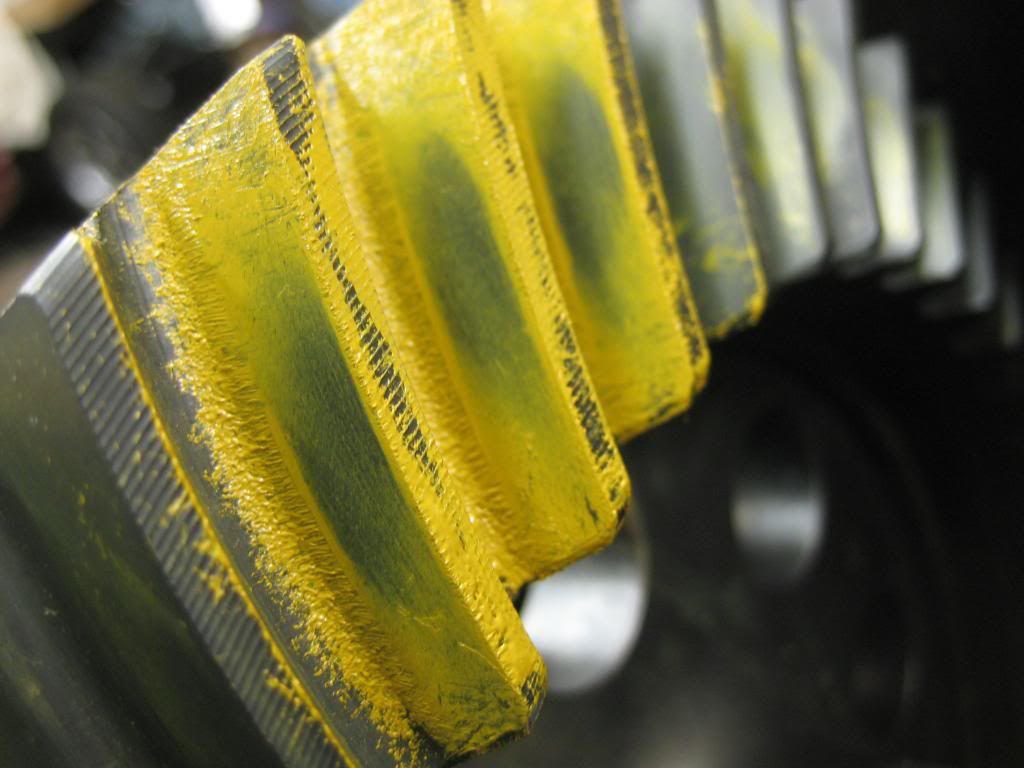

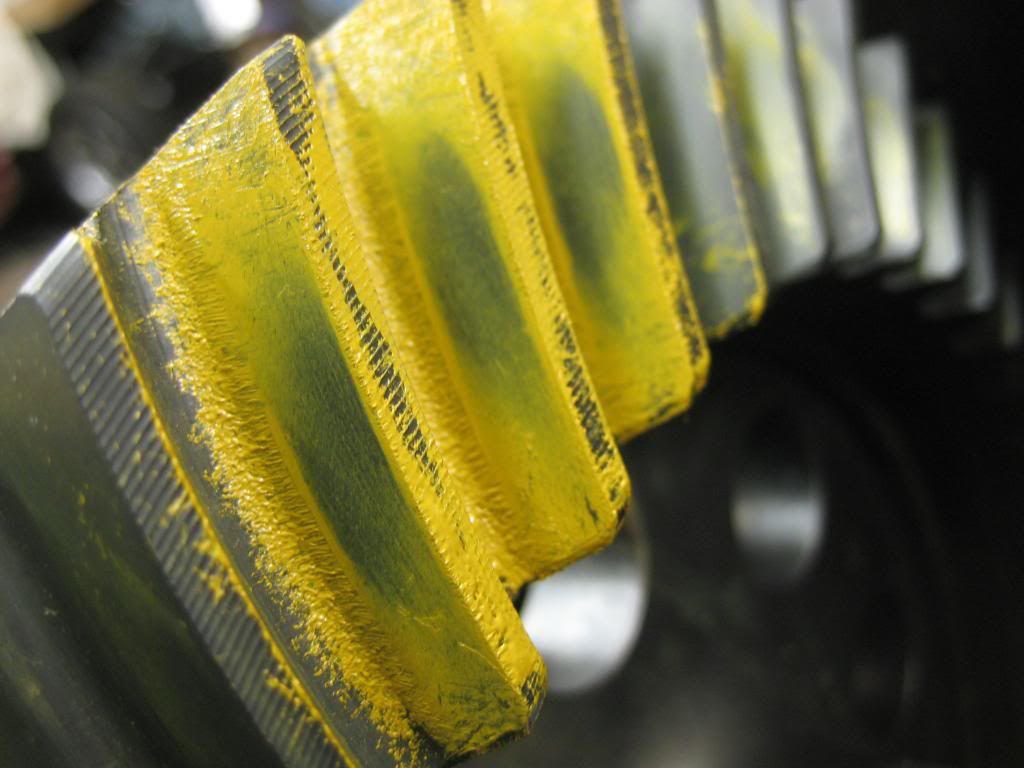

started with the old ?? shims under the pinion race. was too much the ?? of the tooth with a flat bottom?? . Changed it out to .?? and got this. Looks a lot better, Not sure if need to change anything?? BL is ??

??

started with the old ?? shims under the pinion race. was too much the ?? of the tooth with a flat bottom?? . Changed it out to .?? and got this. Looks a lot better, Not sure if need to change anything?? BL is ??

Looks “ideal”. Which is absolutely fantastic because most install instructions state that most likely you will not get an ideal pattern and you’ll have to adjust till you can find an “acceptable” gear pattern.

I did a ford 8.8 a summer or two ago at Swerve. Holy fuck was it a pain in the ass (took it in and out ~40 times) but I too ended up with a gear pattern just like yours. Isn’t perfection grand?

do the gears eventually wear and make a lot more contact or is that just the contact a diff gear makes?

That only took you two tries? That’s fantastic, those contact points look perfect.

No they don’t make more contact than what you see (under load, maybe I dunno). If you were doing this job and saw a crap gear pattern due to crappy shimming and pinion depth, you’d understand how much of a pain in the ass it is to get a pattern like he got. When the pattern is off it can make the rear end noisy from being too tight of you’ll end up with actual mechanical damage of the gear teeth. Do a quick search on google on a rear end gearing change for a diy and you’ll prob learn a thing or two, I sure did.

Pattern does look nice.Backlash is correct at .009.The most inportant part of reading the patterens is how deep its is in the tooth,and it looks like your perfectly centered.I always start with the factory shims and go from there.The spicer gears usually setup real nice and easy compared to other brand sets.

I’m gonna gona beat the shit of of these gears.

What’s the gear ratio?

4.56 for the highway

The ford 8.8 spec I did was some crazy high spec too and you shoulda seen the shit I bent trying to hold it in place for proper torqueing. I ended up building a jig to hold it all in place and still thought I was going to break the damn bar I was tightening with. It was one of those situations where you say to yourself that there is all sorts off ways to get hurt doing it.

Lol

two tries???

i watched someone do this for 3 hours (10+ tries) today in lab.

and you look spot on too :tup:

One try  LOL

LOL

yeah, the ford 8.8 has the crush sleeve and you actually tighten till you get a specific in/lb drag torque using a 1/4" beam style wrench.

I’m told the 9 inch rear ends have a special tool that you just turn to adjust the shimming on the carrier bearings versus the evil shims used on the 8.8

9 inch fords and 8 3/4 mopars use the side carrier screw in things that you adjust the baslash with.i cant think of the name.i like the ones with the side shims alittle more,sometimes with the screw in ones its very easy to start the threads not correct and it will cause a big mess.Its a fine thread.

Very nice now come do some 3.55’s in my 30th…Same S60!!

I think m

3.73’s with the turbo won’t be enough unless i slam a 28 inch tire on her. I have 26 inch slicks that still have life left i want to use so the 3.55/54 will put me where i need to be. I expect the car to hit the 140’s.

I think you will be

i run 26x11.5x16 et street slicks… gets me to 137 at 6600 if they don’t grow any. They are run at 16psi as that has held the best so far, anything lower and it felt too hairy.