Nothing much to report, just little things I’m getting together.

Sold both my BMW diffs (2.81 and 3.15), both MAFs, the base rails of my roof rack, and the Camaro (rear sump) oil pan.

I received my ARP head bolts, GM MLS 6.0 headgaskets, LS1 harmonic balancer, starter, water pump, and GTO oil pan over the last week. The top end of the engine is ready to go back together, but the machine shop lost the dowels in the heads, so I had to special order 3 of those (1 was left in the block). Can’t assemble it until they get in this weekend. Once I do get those I can finally put the heads back on and torque them down, as well as replace both front and rear main seals as well as a ton of other gaskets I bought. At that point I can put the intake manifold on, and it’ll start to look like a real motor (good timing, because I need to know where I’ll have issues for fabbing the motor mounts).

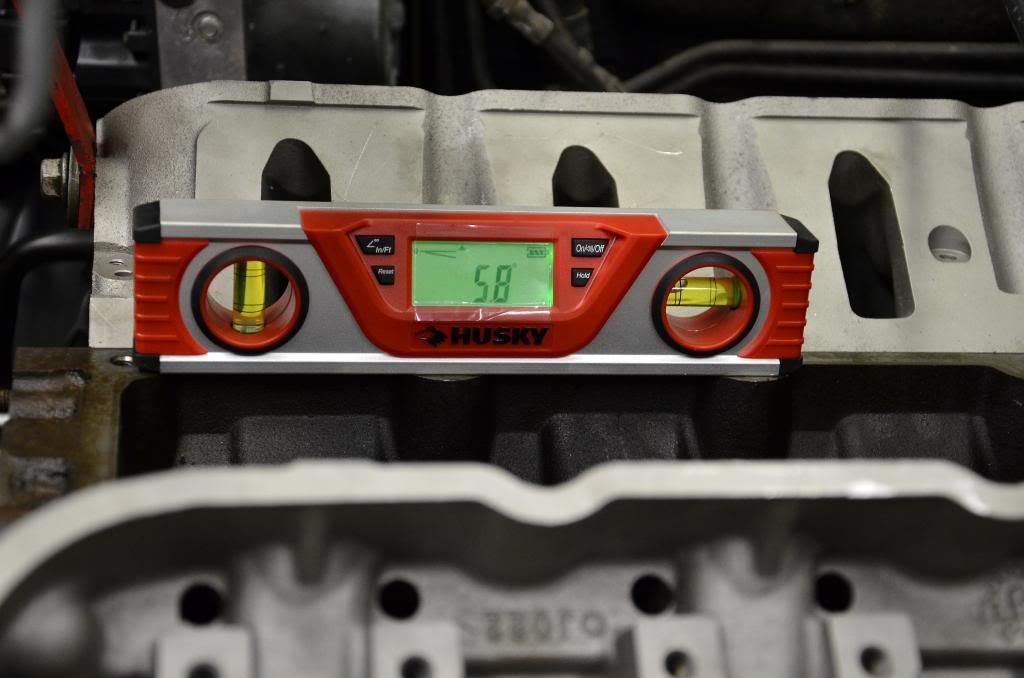

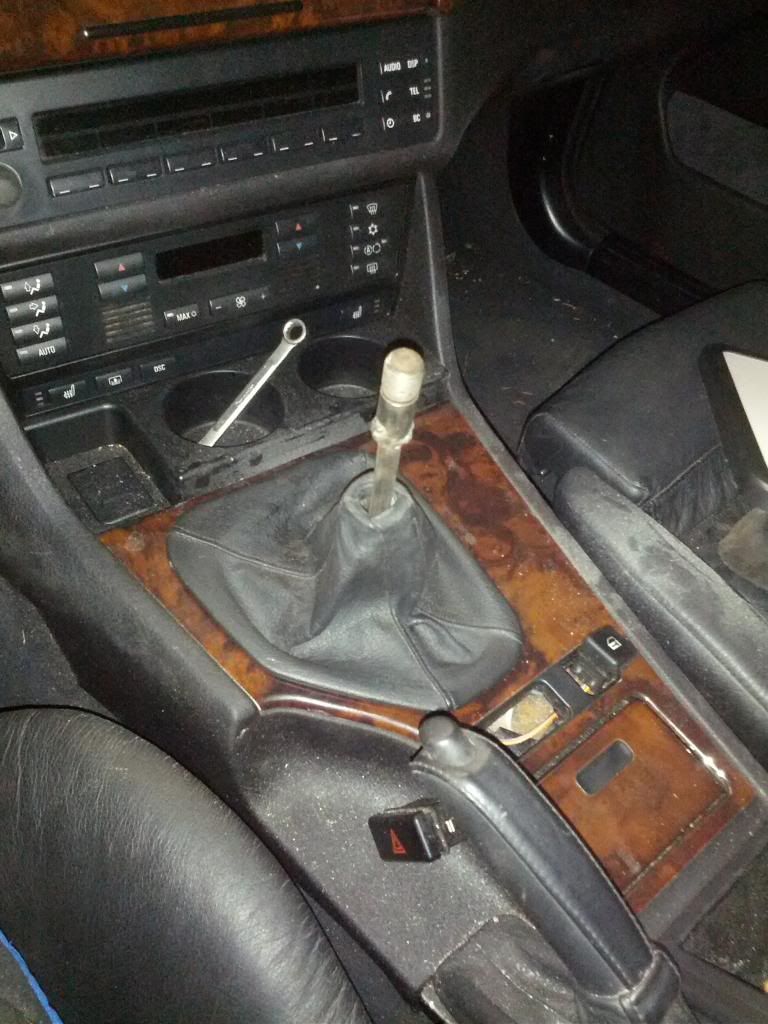

On Saturday, I put the car on some 2x6s I nailed together to raise the car off the ground at all 4 corners. I eyeballed the rough dimensions of the cut on the GTO pan and notched it, test fit, and found that I still need to notch the horizontal portion some more in order for the nose of the motor to come down a few more degrees. With the shifter roughly where it needs to be, the engine is pointing 6* down at the back–I am going for 3*. Having a digital inclinometer accurate to a tenth of a degree is awesome. The motor/pan is resting on a 1" board, so maybe it’s a bit overkill as far as spacing from the crossmember, but I am assuming the new stock rubber engine mounts will squish down some when the weight of the drivetrain comes down onto them.

My right angle grinder backing plate fell apart, and Home Depot was already closed, so I wasn’t able to finish trimming the pan. Today on lunch I went to the store and picked up the proper backing plate/ring along with an 11/32" drill bit, which I’ll need to drill out the boss on the block for the alternator to mount to. I have the LQ4 truck alternator as it came with my motor, but is it the same type as the LS1 style? It looks like any old small car-style alternator. I’ll have to see if there’s a part number on it and cross reference to see if I can reuse it. I’m still on the hunt for a cheap OEM LS1 alternator bracket.

Buying a used LS1 power steering pump was ehhhhhhhhh, so I found a nice cheap one on Rockauto and grabbed that. I still have to find a pulley. Might yank the pulley off the truck PS pump (if I even still have that in the piles of parts) and see if it’s the same diameter (I would assume so).

I had the sheet metal shop at work punch me out a few engine plates, bolted those to the motor. I also grabbed some short lengths of 2" square thick wall tube steel out of the scrap bin, those will be used to make up the driver’s side mount around the steering box. I did a rough “from memory” sketch on CAD at work of the driver’s side mount. The passenger side will be easier, should be just one length (straight shot from the engine plate to the rubber isolator). My little farmhand MIG welder is wayyyy too shitty to actually weld all the way through and get full penetration so I’ll just be tacking the shit out of it and having the shop at work weld it all up for me. exhaust should be okay to weld due to the thinner wall pipe, I’m just a crappy welder, but this will be good practice.

Should have some spare time tomorrow on my day off to finish trimming the GTO pan, maybe start to cut up the tube steel to make the mounts.