As some of you know the Firehawk suffered a painful blow last November. The #7 cylinder went lean and melted the piston right through. No one was to blame except for my own negligence in not even looking at the tune before I put’er to the wood (alongside TurboLS1SS) after changing the entire fuel system. Classic mistake, it will only happen once. :banghead: Dammit Bill I told you I should have just kept it in the garage!

So it sat all winter while I procrastinated at the daunting task of actually looking to see what the extent of the damage was. I was hoping for the best, but expecting the worst, so we started pulling it apart to see what was up.

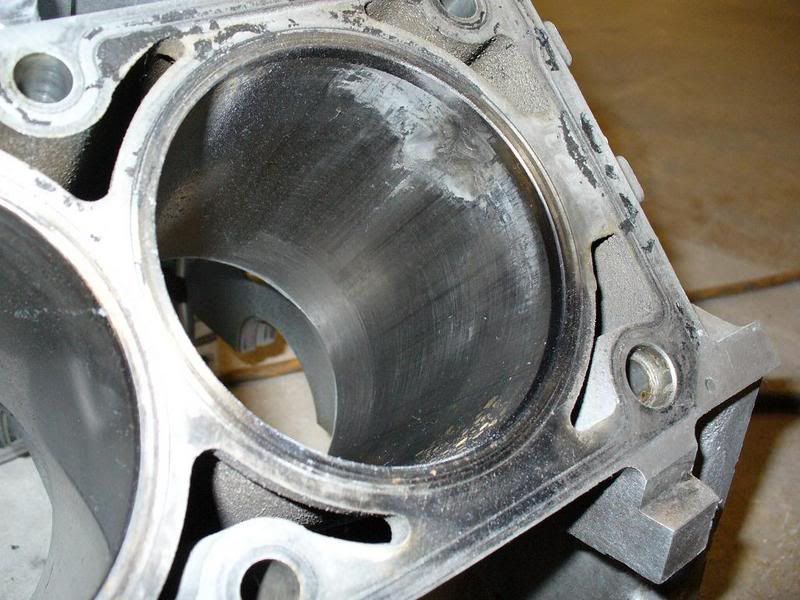

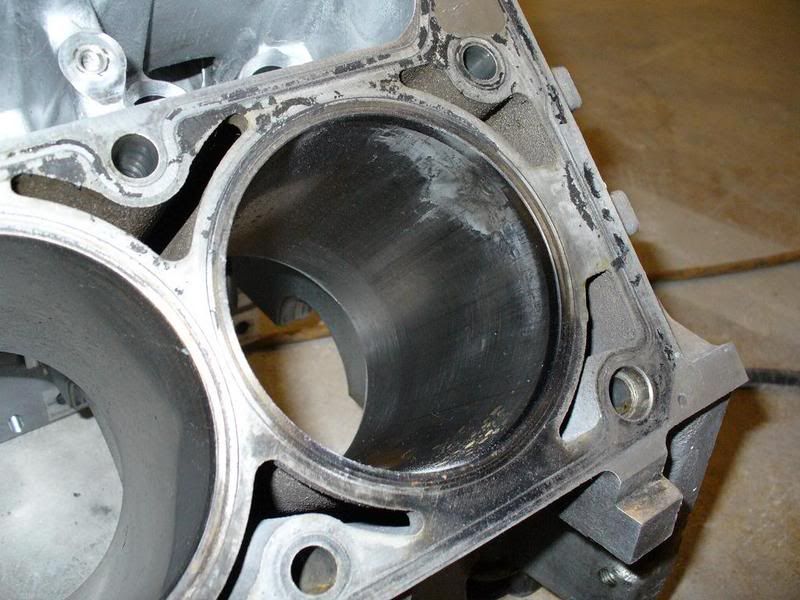

The culprit. (1) MELTED piston! As you can see the damage not only took out the piston but also the cylinder sleeve. RIP LS1. She lived a happy life.

Luckily the cylinder head was not heavily damaged and easily repaired. I did replace the exhaust valve because aluminum had embedded on the seat.

One item to note is that the engine was pristine inside. It hurt to taking it apart know that there was absolutely nothing wrong with it. Bearings were clean (even after the carnage) except for the obvious fresh metal shavings, the cylinders still had all the crosshatch, the piston tops were smooth and clean, cam bearings practically reusable. The engine didn’t burn oil and had practically no signs of significant wear and tear. As some people tend to discredit Jason, he builds one hell of an engine regardless of what anyone says. His meticulousness far exceeds mine (and I thought I was OCD) This was all the evidence I needed to have him do up a second revision.

On to bigger and better things.

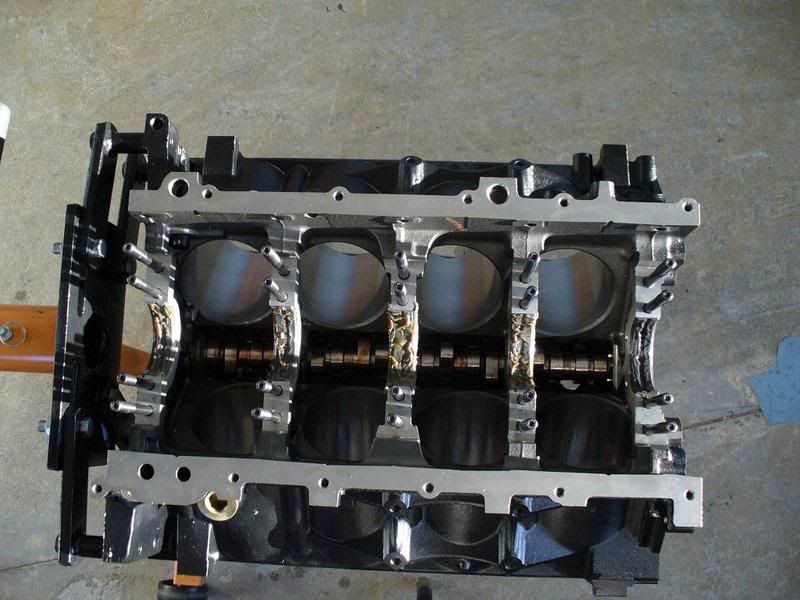

LQ9 Iron Block. Bigger, cheaper, stronger. Can’t go wrong. I considered all the options once I knew I needed a new block. This option won out.

Sweet coated pistons. The pistons were first media blasted, prep’d and coated. Bake to perfection at 350F for one hour. Credit to Jason the baker on this one!

New cam or not to new cam, nothing to see here folks move along.

Forged Crank. This was a tough decision. With the large number of people making stupid HP with stock cranks, I was originally planning on using a stocker. But when it came down to it, I just couldn’t put it in the block. All the little voices kept telling me it was a bad idea. Consider it insurance I guess.

New Oil pump and timing set. I thought the oil pump would be ok, but upon further examination the aluminum had was caked on the old gears. Oh well, just $$$ right.

7/8/07

After a couple of late nights at the shop, a couple packs of red bull, twizzlers and Pringles we made some progress. Everything went together real nice.

Of course once we got the engine ready for installation there was no stopping, work til the sun comes up.

On the cradle she goes. Shake and Bake!

Pat lending a helping hand

5:30AM photo op.

Would you like boost with your displacement?

Again, Huge credit and thanks to: without you guys this would be impossible!

Jason (J&J) – “I wanna go fast”

Bill (TurboLS1) – “uhhhh”

Jesse (Muscle5.0) – “mad leet skillz”

Pat (psychopjv) – “Just do it”