I got the 3/4" maxline kit in over the weekend. It’s a bit larger than I thought it’d be. Probably overkill for my garage but it’s good to 175cfm if I ever go larger. Gotta get it installed now

you’ll enjoy the flow and the air reserve 3/4 provides.

Did you get this compressor in Cobleskill??? My friend had one and sold it I would have bought it had I known what he wanted for it…It was only 6 month old and he sold it for half what he paid…Bill

i bought it new at tractor supply. it wasn’t very expensive. I looked on craigslist for used ones but they were all about the same price as new ones or beat to shit

He got $600 for it it was 80gal pro model not sure of the CFMs it was almost 2000 new…

my old man’s shop air is PVC, it’s been that way for 20 or 30 years, he hasn’t had any issuse with it, and he’s got a big 100 gallon main compressor and a backup 80 gallon.

gallon reserve has nothing to do with the equation.

Pressure, plastic temps & impacts are the things that should be considered when using PVC for air lines. Go take a 1/2" ratchet and hit a charged air line as hard as you can when its 12 degs out… report back how that goes.

If ya run it out of harms way, or inside walls not on them its great stuff. Also I dont think it passes for industrial inspections if your running a business from the location… so that tells ya something right there.

I’m not going to argue about it, because noones going to listen anyway, but I know that when I pulled my system down I saw I was very lucky I didn’t have an issue. The oil discharge from the compressor was accumulating in the joints and degrading the pvc… to the point i snapped said joints with 2 fingers. Do w/e the fuck you want though, aint my shop I don’t gotta work in there.

Yeah PVC is not the best idea for long term. Black pipe is racist so can’t use that.

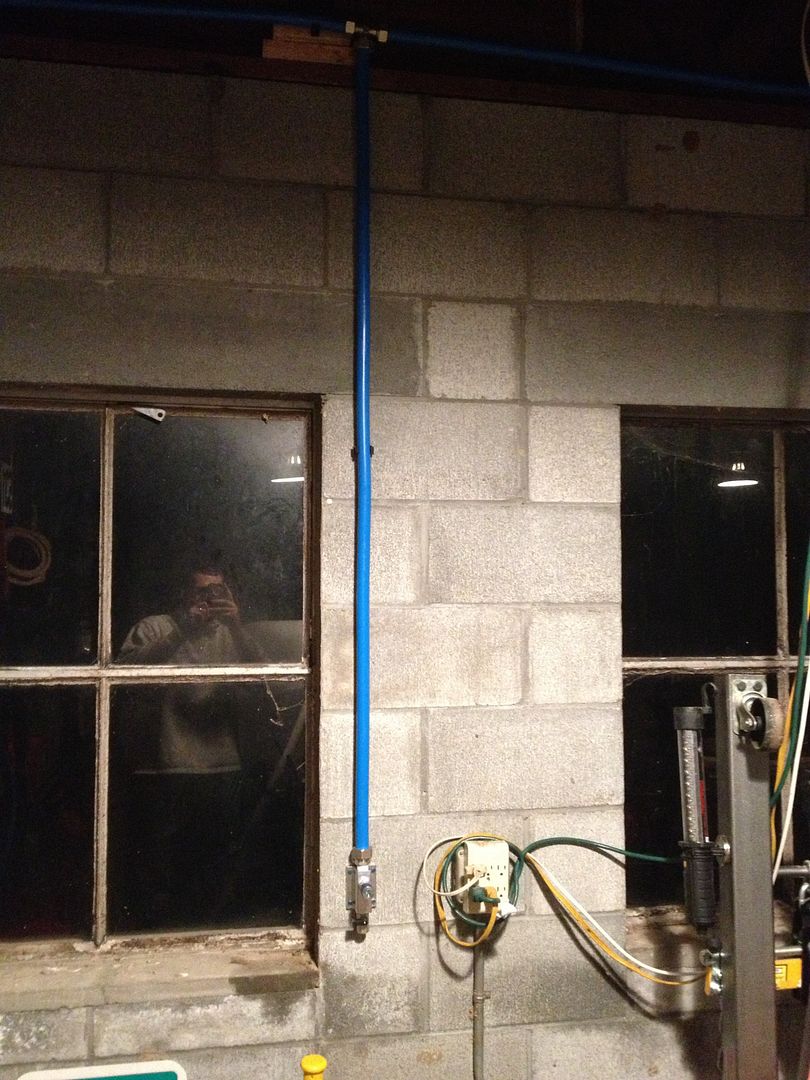

Ran all the lines in my garage yesterday. It took a bit longer than I had anticipated but I am all done now and it came out great. I used the 3/4" Maxline. It’s aluminum lined and comes in a 100’ roll that’s about 2’ in diameter so it was a bitch to unroll and straighten out. In hindsight i’m sure the 1/2" kit would have been a lot quicker to run and been fine for me but I ended up going the 3/4" route since it wasn’t much more and can handle 175psi if I want to upgrade my compressor in the future. I’ll get some pics up in the next day or two.

For anyone looking into this stuff I would recommend it. Although it was time consuming to straighten out I am very pleased with the end result.

yeah straightening it out has to blow… i would have spent 5 hours making a 4 roller feed thing to crank it though to straighten it perfectly, I hate perfectionist ADD sometimes. lol

You did the right thing though, over build dont under build and thank yourself later.

100’ of 3/4 adds 2.3 gal of air reserve too btw. for a garage its nbd, but for a big ass place that adds up to alot of aditional air volume.

I ran the line through a 6’ section of pvc to straighten it out. it helped a little bit but didn’t get it perfect. the stuff has a pretty good memory lol

thats a good idea. yeah its like brake line, without using 4 parallel dies to pass it though it is mission impossible.

looks great man. good job!

Nice job…Looks great…Love those fittings…Bill

Looks great!