Sobo asked me to take a look at the cluster out of his RX7. The odometer was not working and there was an issue with a flickering LED. The LED was an issue with the socket. I had to modify the LED leads to make constant contact on the base (No pics of that).

This is how I fixed the odometer. There really is not much info here but maybe you will learn a thing or two or ask a question…where are all here to share, right?

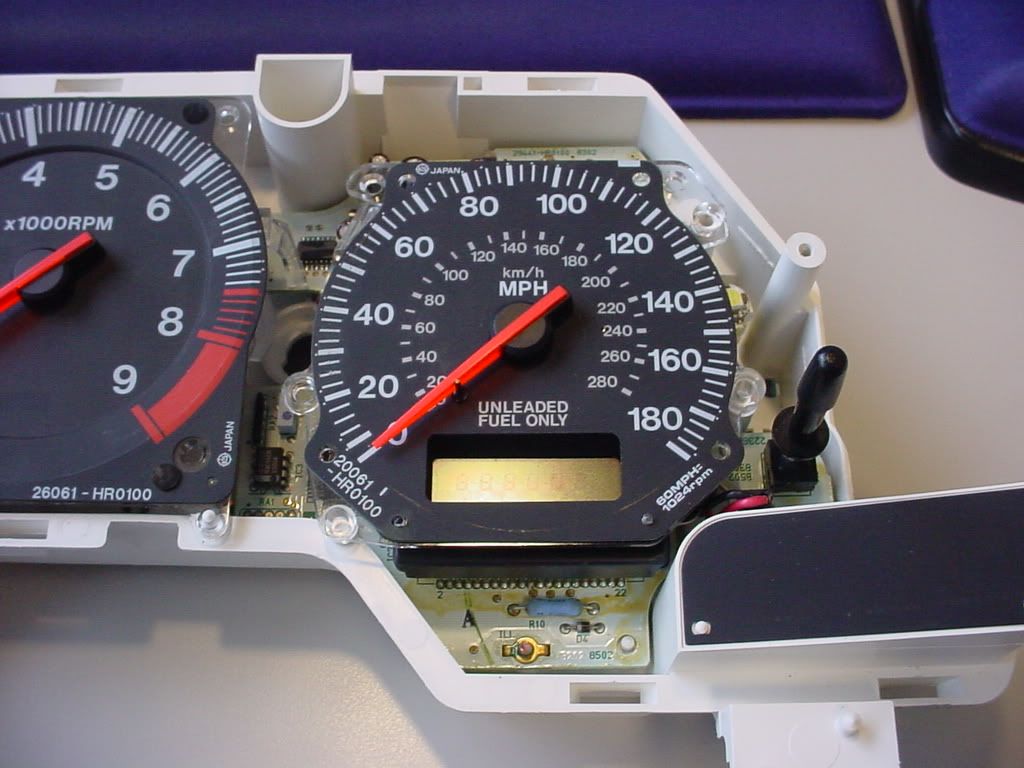

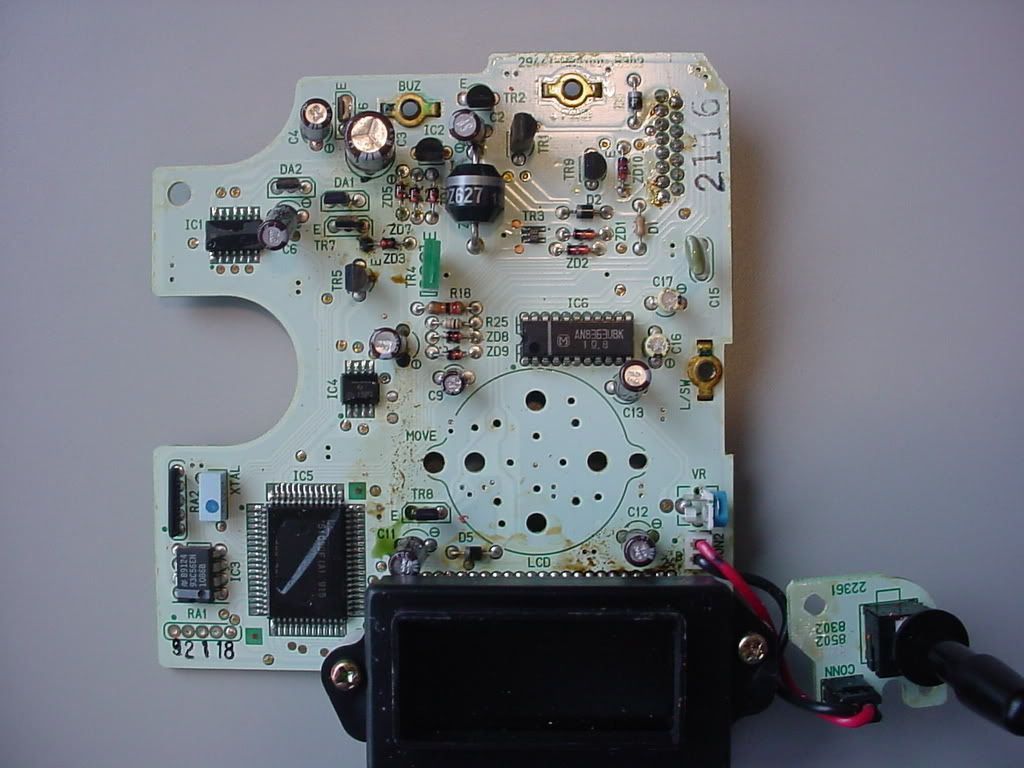

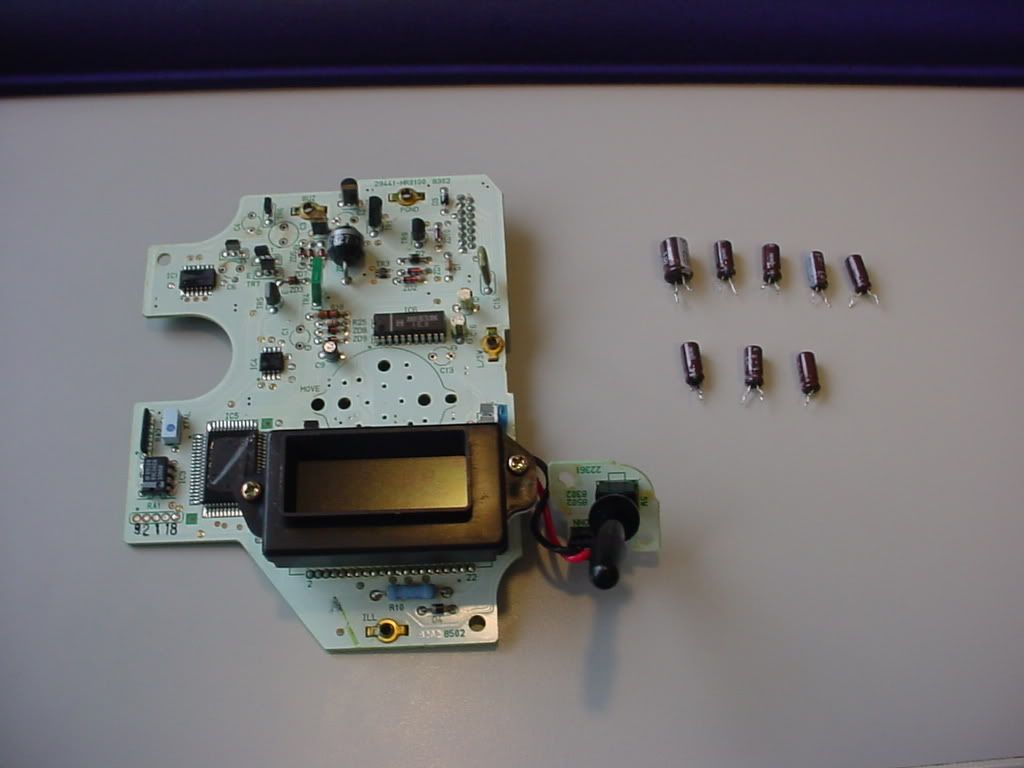

Here is the cluster untouched.

Ok I touched it…

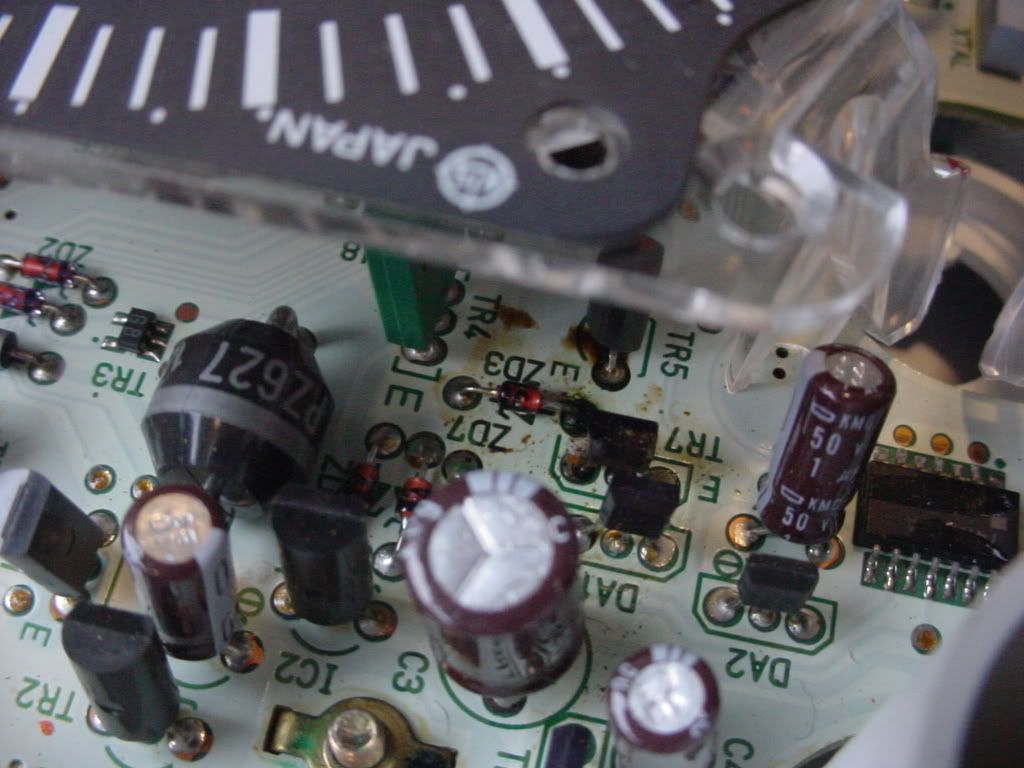

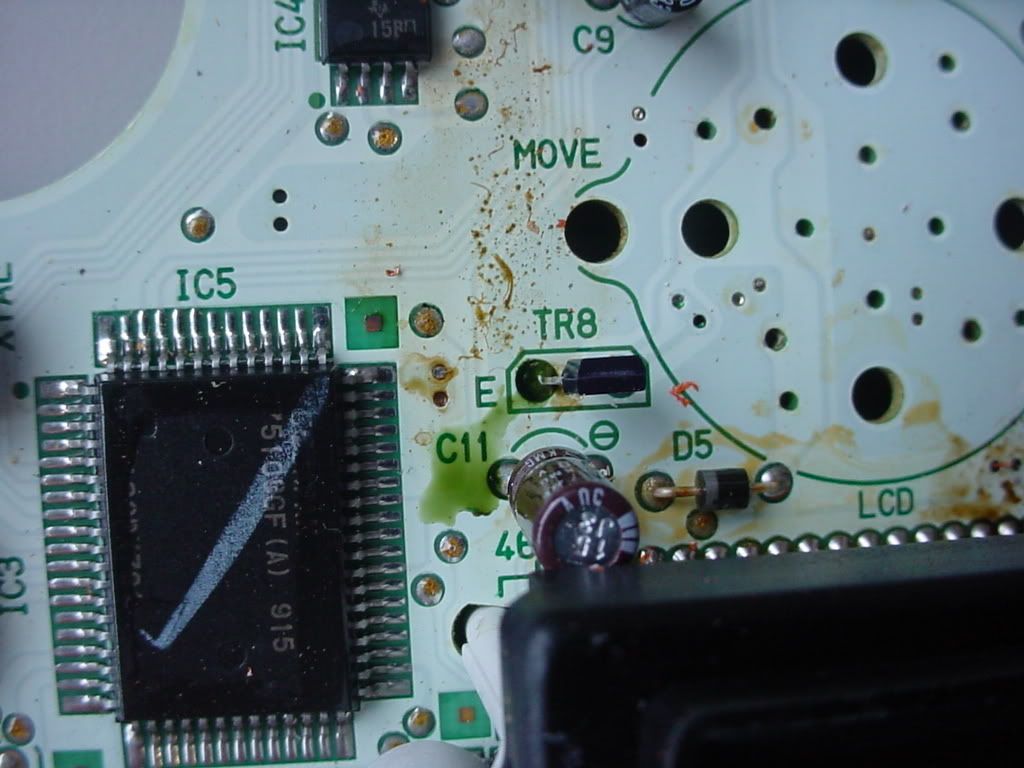

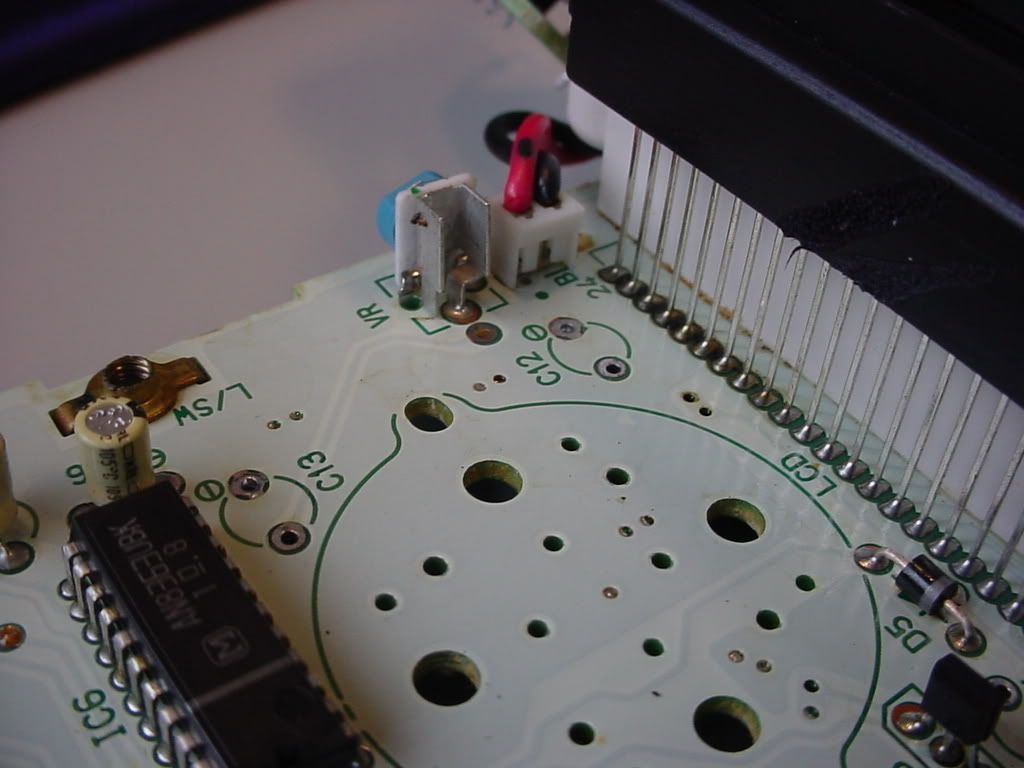

Closer inspection. You can see something happened.

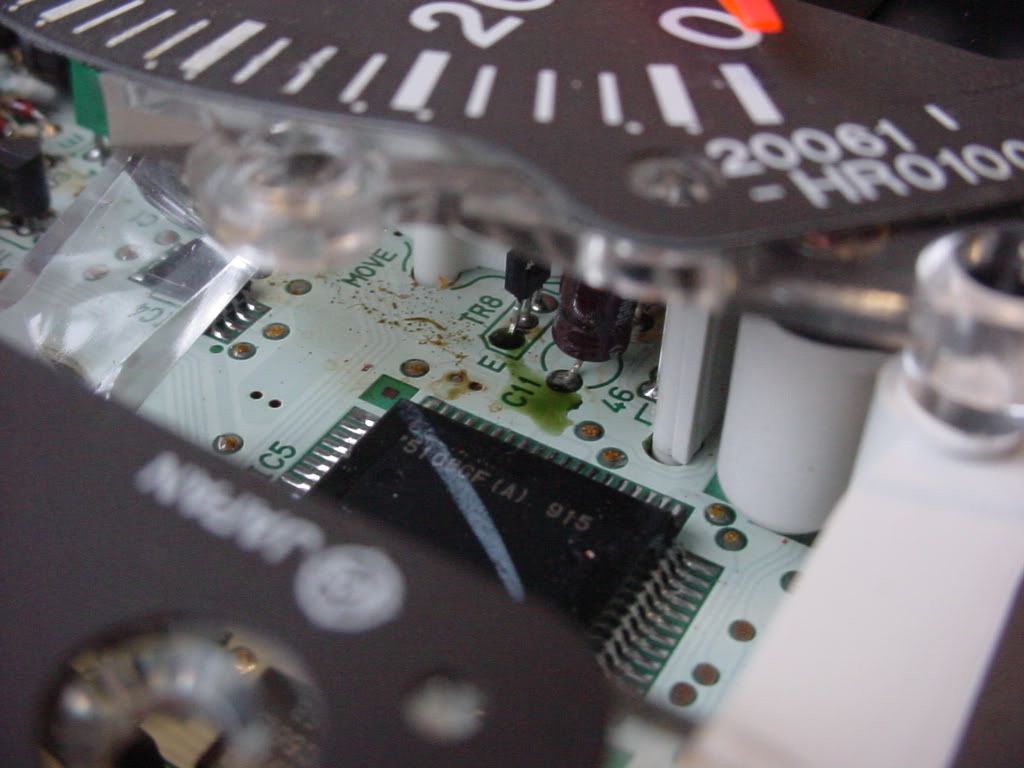

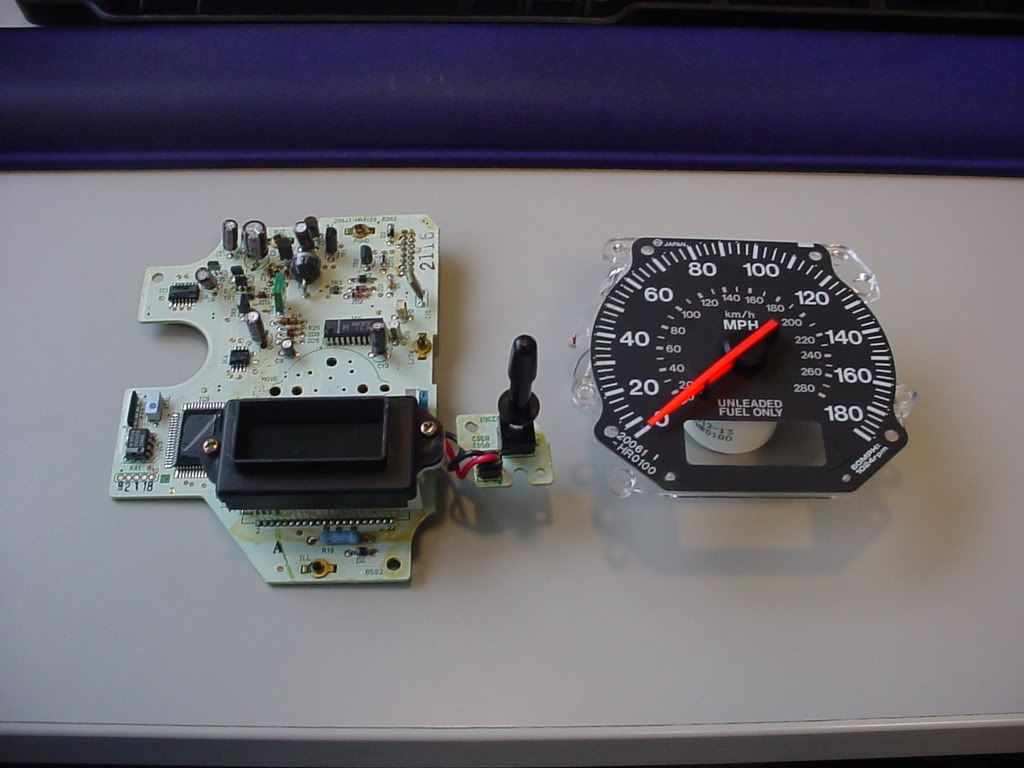

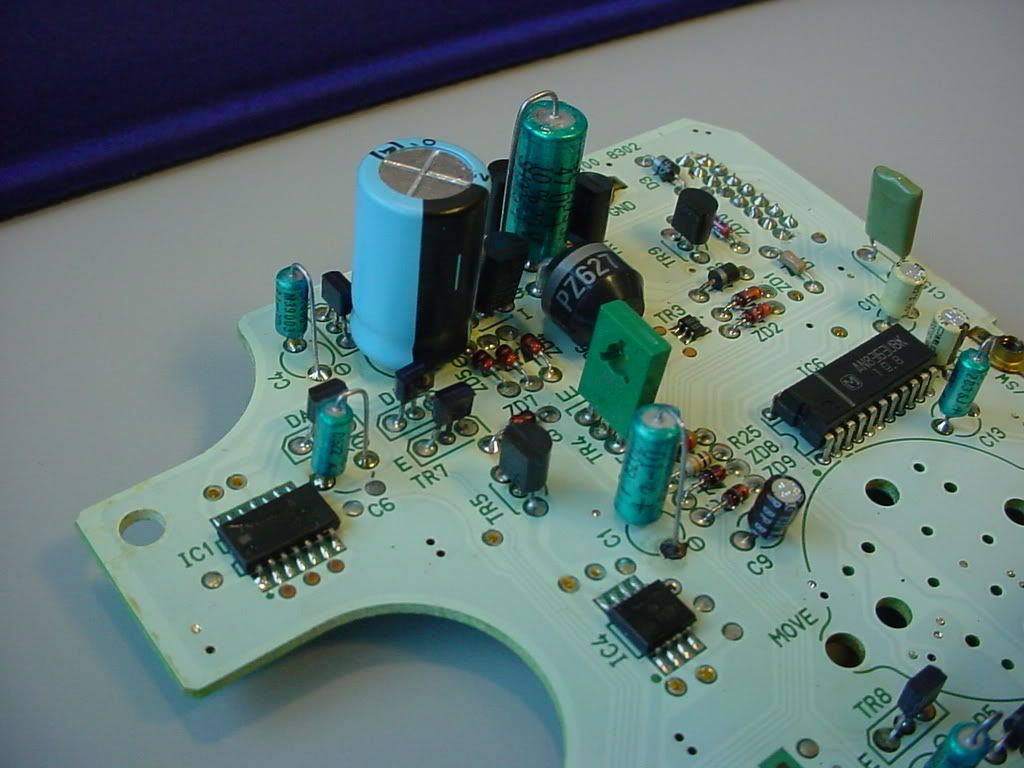

Then I pulled it apart.

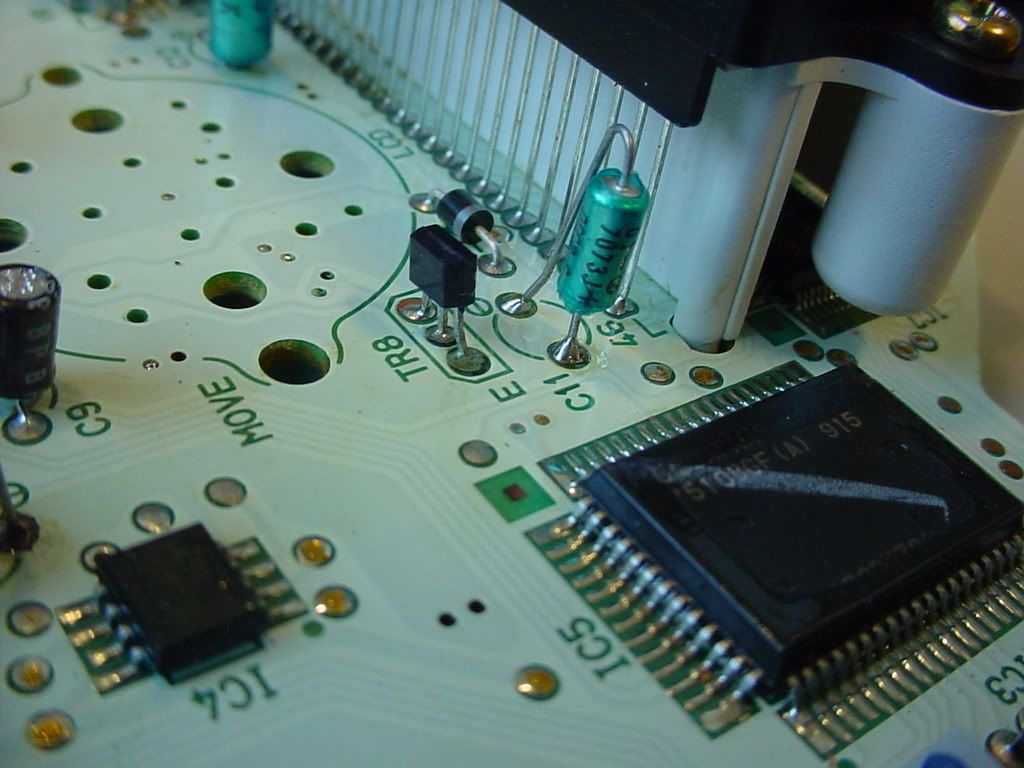

CLOSER Inspection. Ugh. Yummy.

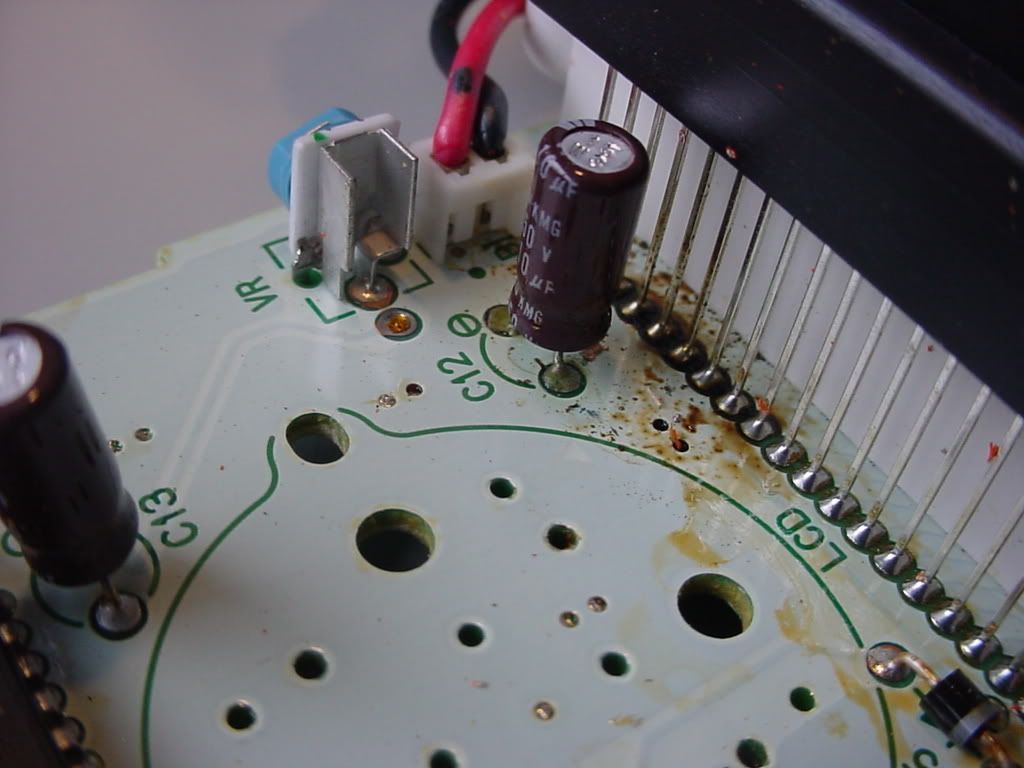

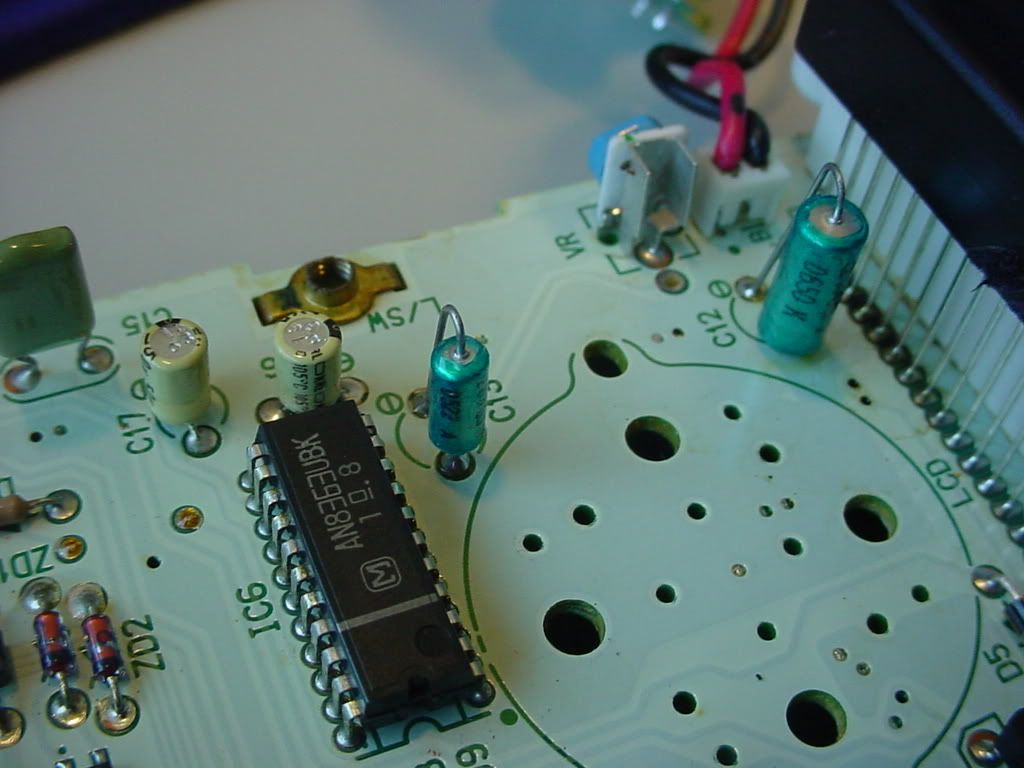

Capacitors C1, C3, C4, and C12 where shot. This is commonly know as “Capacitor plague” in industry today but was not ruled a failure point until early 2000. Over time the capacitor literally “cooks” which leads to leaking electrolyte. This causes the component to fail. I ripped all potentially “Bad” capacitors out. Based on their size and rating it is pretty easy to weed out the bad ones.

Then cleaned the PCB. If you have ever looked at a commercial PCB you see all the flux residue left over from their highly controlled processes.

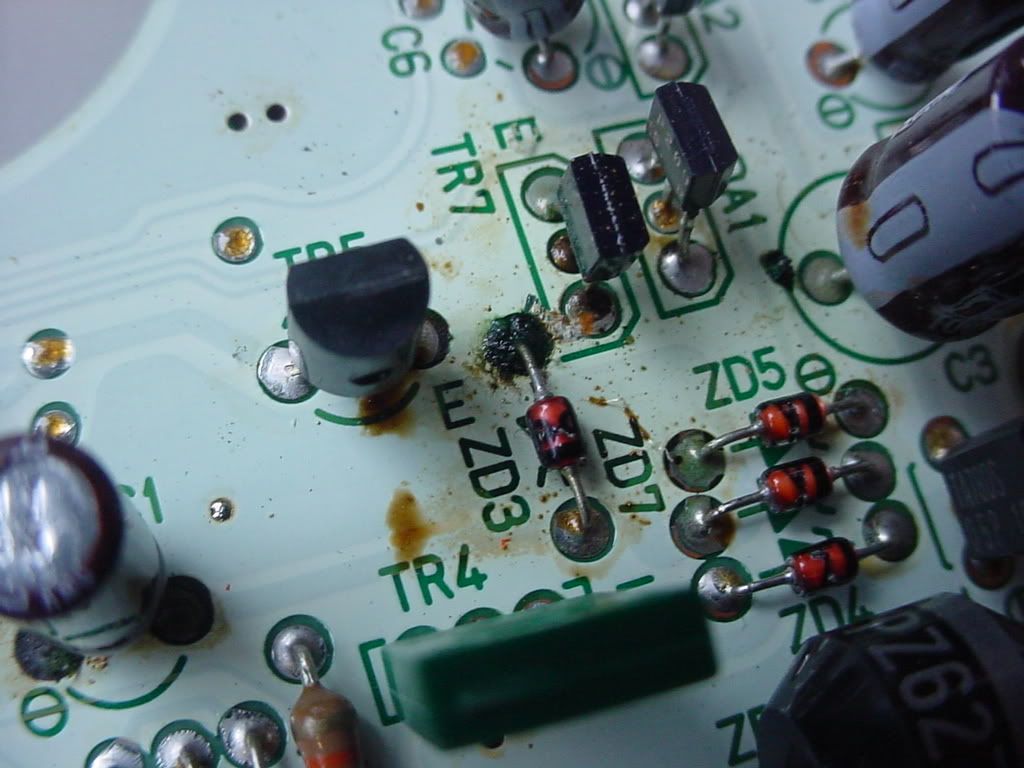

I tested each part that appeared damaged. This Zener Diode was pretty beaten up at the solder termination on the Anode. However, the part itself was good. I removed and resoldered the joint. Much better.

(Again for reference)

I didn’t grab a shot of the dirty PCB rear but all the LCD pins, Speedo pins, and large thru-hole parts had a lot of residue. It is unrelated to what I am doing but I cleaned that anyways.

With the bad Caps out and the board ready to go I bent, terminated, and cleaned the new parts. I replaced these caps:

- C1 - 10 uF

- C2 - 47 uF

- C3 - 1,000 uF

- C4 - 1 uF

- C6 - 1 uF

- C11 - 2.2 uF

- C12 - 10 uF

- C13 - 1uF

I switched to a solid axial Tantalum capacitors for most of the radial capacitors I pulled out. The solid Tantalum is highly reliable and will virtually not break down. The 1,000 uF cap I replace with a new electrolyte, but this time I switched to a larger wattage capacitor. While the component is much larger I was able to fit it on the PCB. This allows for a lower risk of being overdriven and potentially no risk of breakdown.

All done and back in service.

Before you toss that used non-working part in the trash, take it apart and try to fix it. Or, shoot me a PM.

Total part cost to fix: Around $5.

Total time to fix: 10 hours.