I got a whole lot done today (including the last ride with the original LS1) and took a lot of pictures. Those updates will come later but for now I just want to keep a log of what I have started disassembling; once the reassembly comes, I’ll use it as a guide to see if I forget anything when it’s going back together

This list starts with a running, driving car

Drained coolant

Drained oil

Removed wheels

Removed axle back, disconnected vacuum lines to cutouts

Removed midpipes, unplugged and de-routed downstream O2 sensors

Unplugged and derouted primary O2 sensors.

*Note, standard off the shelf white zip ties were really brittle due to longtube header

heat and snapped with little effort. Need higher temp solution to secure wiring

Disconnected left rear outer frame ground point (10mm), rear large harness on pass. side wheel well

Disconnect large 10 pin connector on rear passenger side of tunnel

Disconnected rear wheel speed sensors

Removed zillion tunnel plate bolts and plate itself. Thank God for power tools

Rear upper control arm bolts removed

Parking brake brackets removed

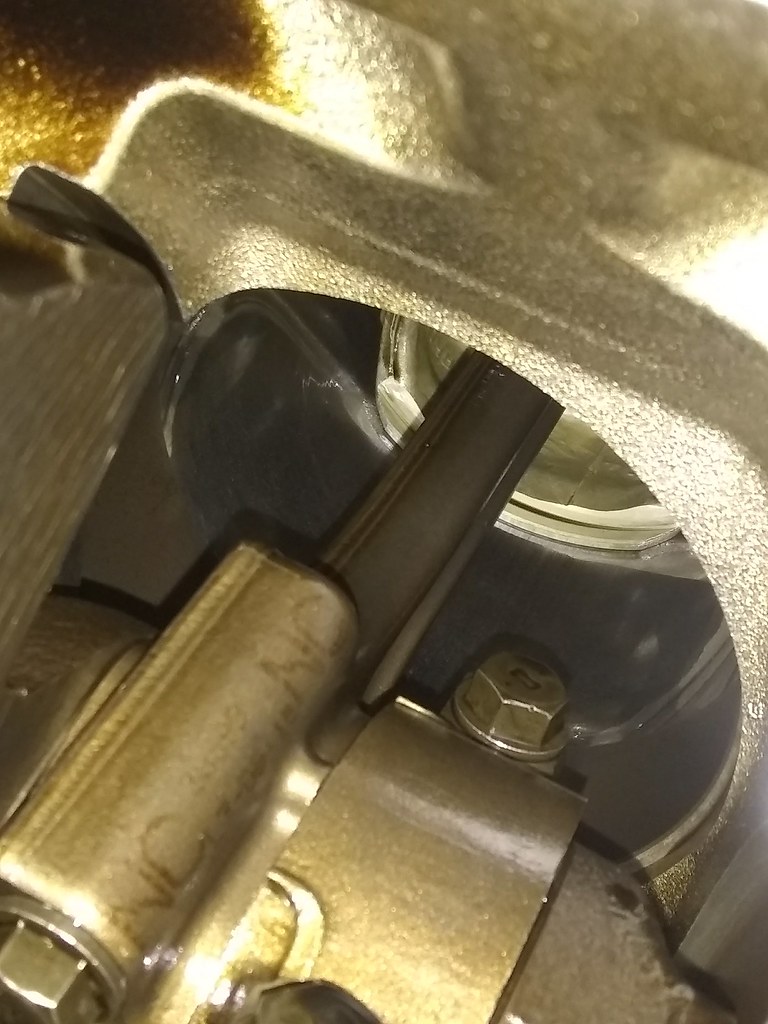

Rear brake lines removed and plugged to prevent fluid loss. Normally not necessary but I’ll be upgrading to stainless lines when it all goes back together.

Rear lower shock bolts removed

4x brake line 10mm brackets removed

Front upper control arms removed, attention to washer/shim location

Front brake hoses removed and plugged, etc.

Disconnect pigtail that loops under front sway bar

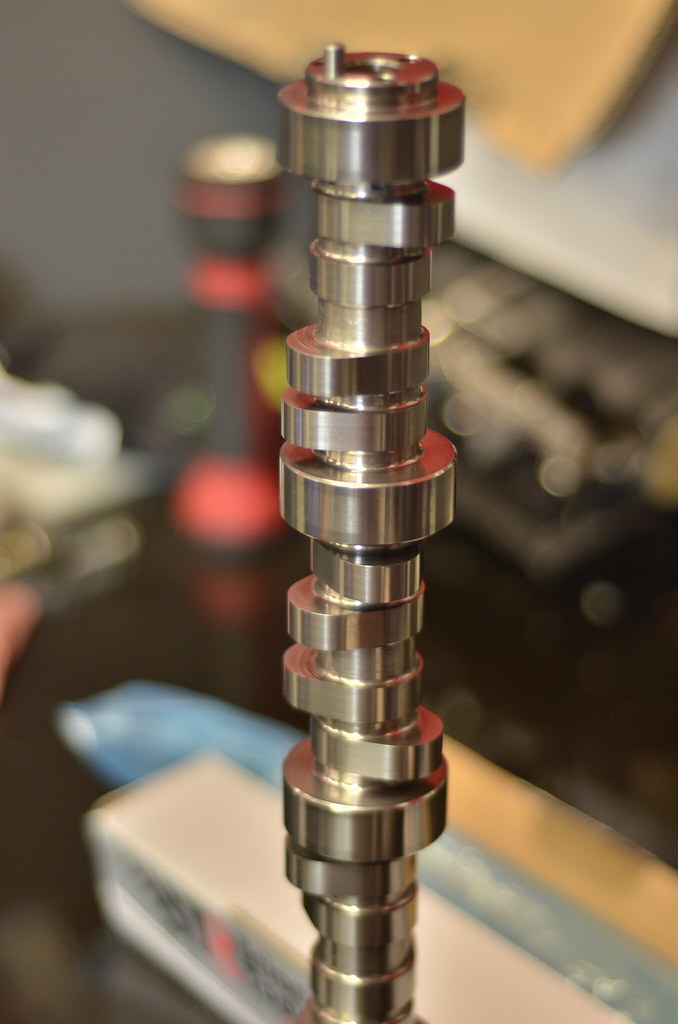

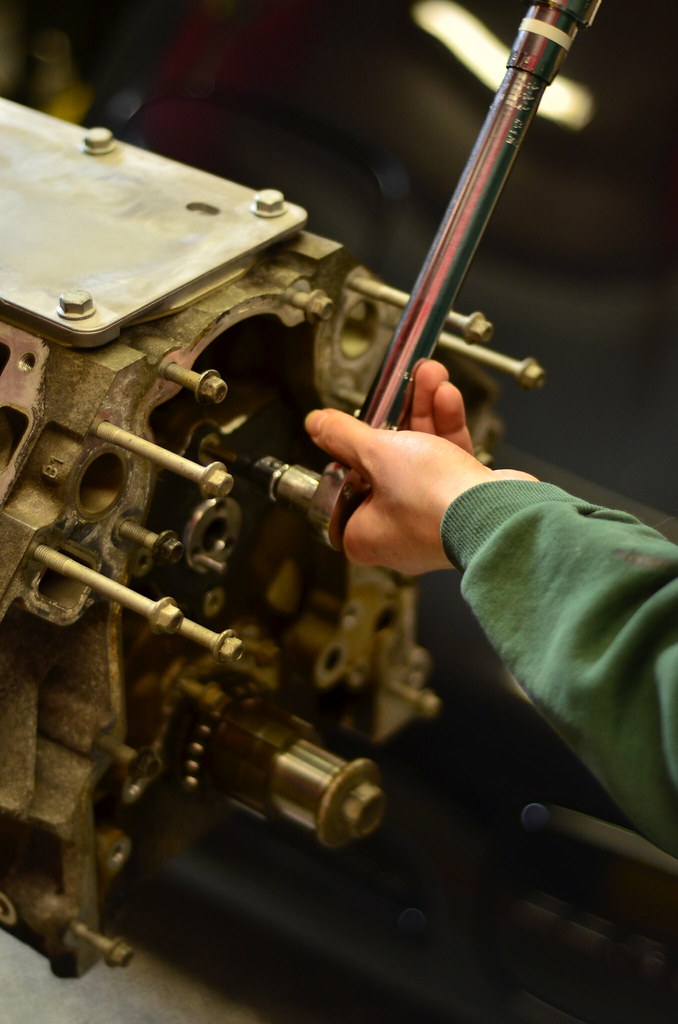

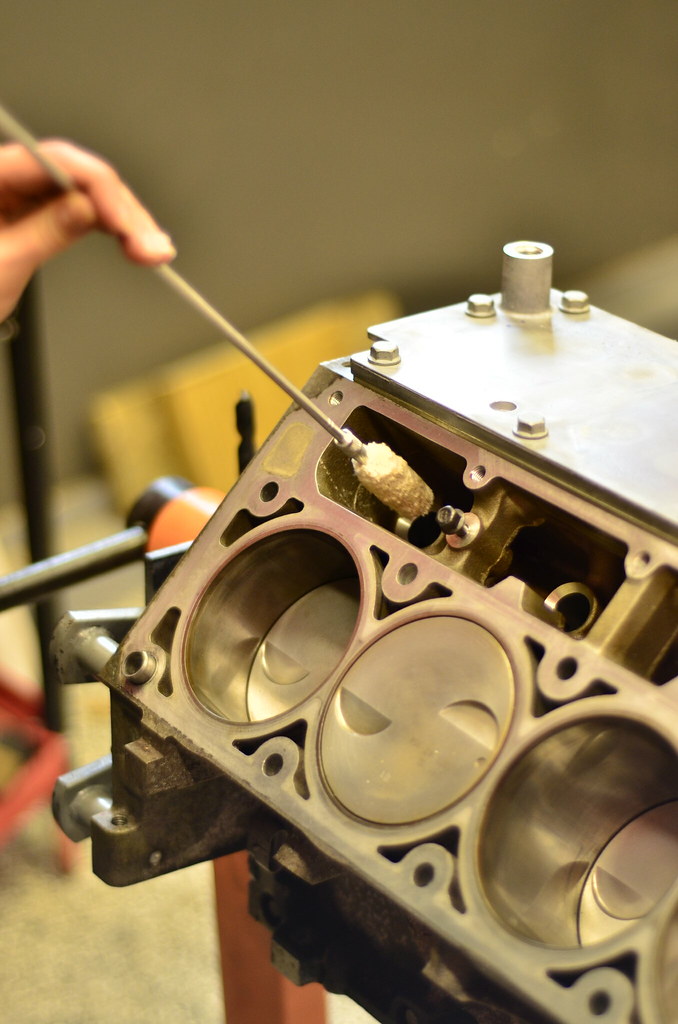

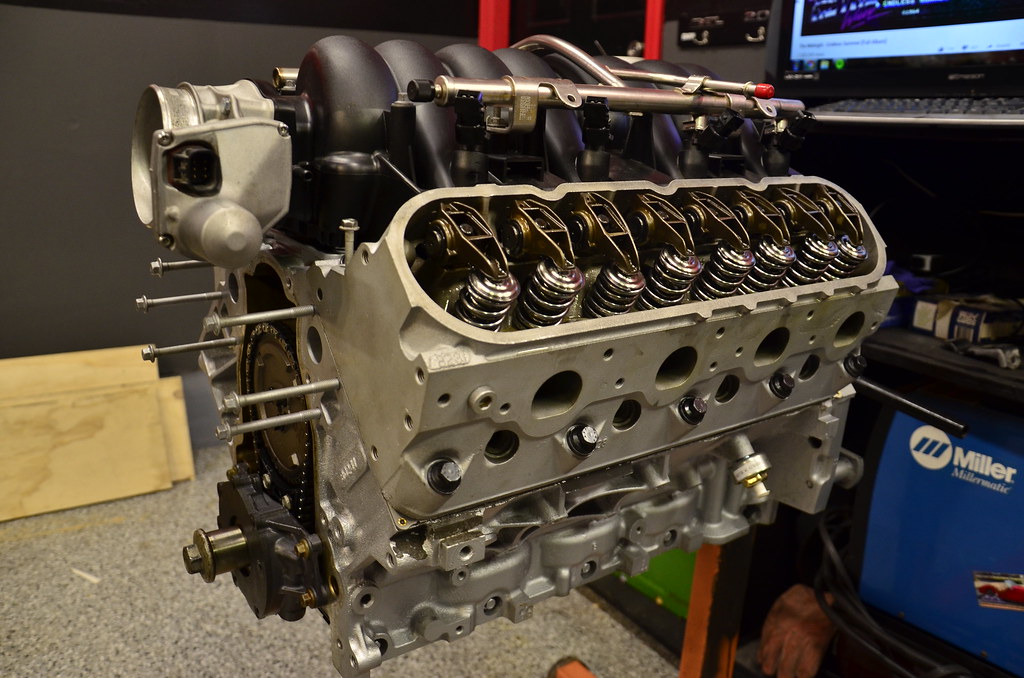

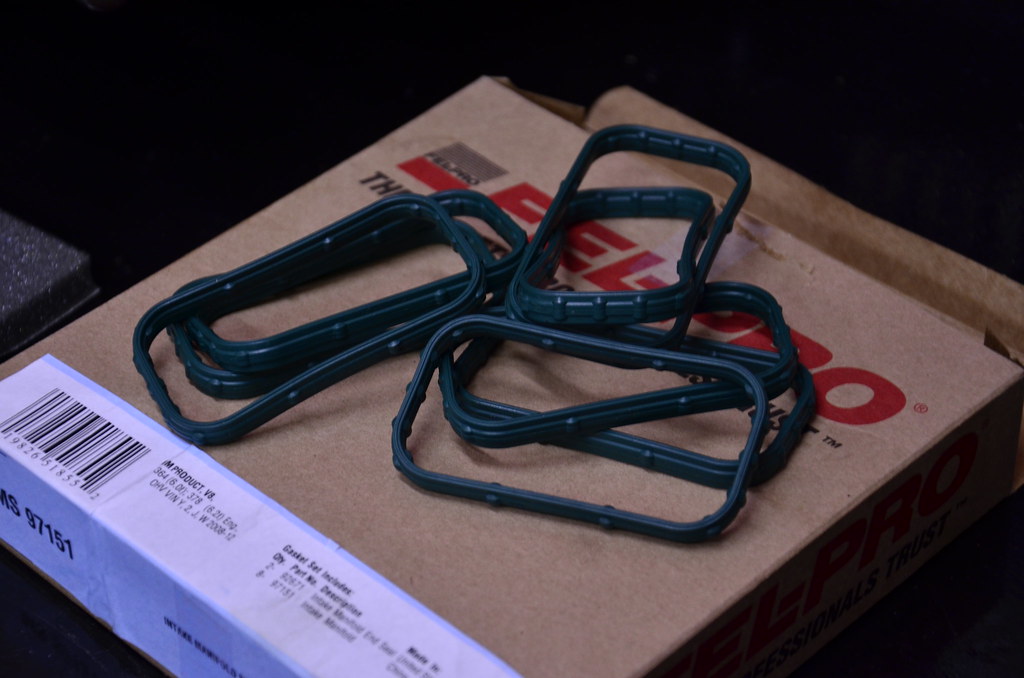

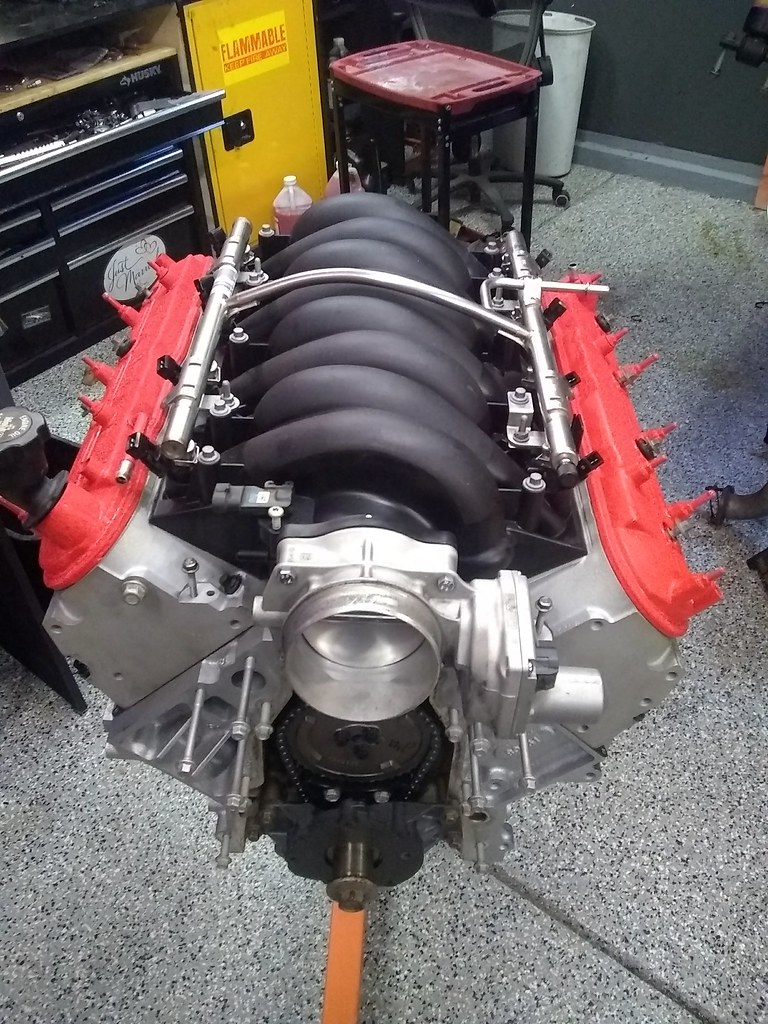

I need to buy a 12 point socket to install the pushrods and rockers tomorrow, then the new motor is nearly done. Now it’s beer time.