I am building a BIG, as you can see media blast cabinet. Spent $300 on the parts and media, shipped to my door from TP Tools. Homedepot bill was $124 for the wood and other parts.

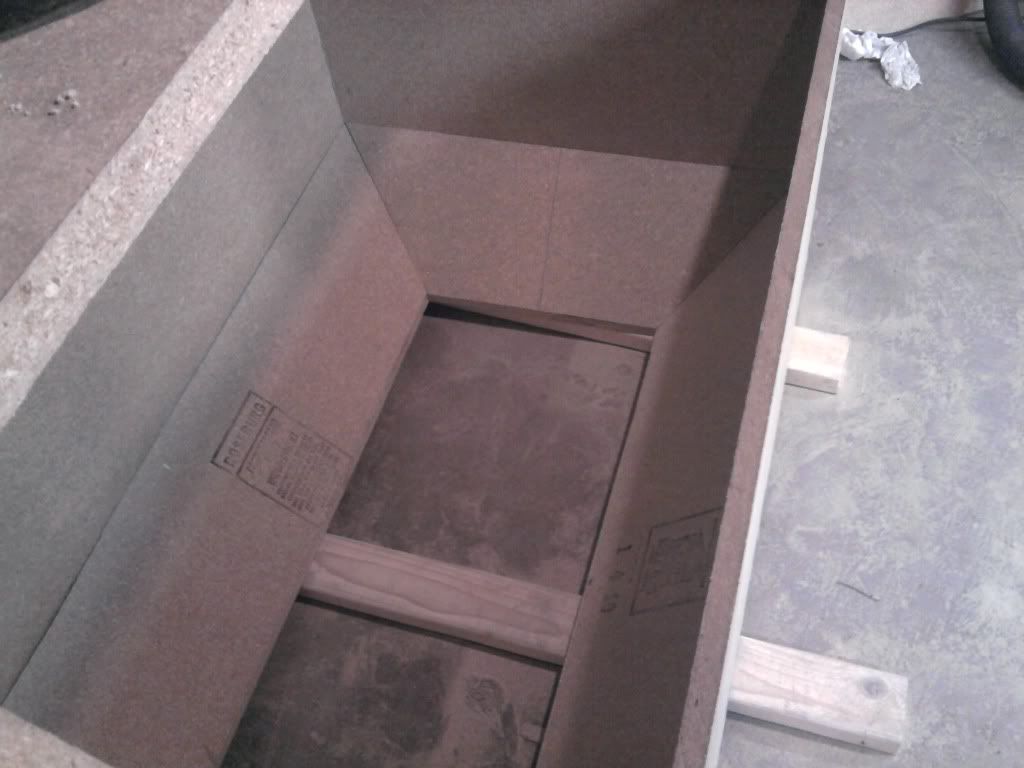

Last night VOT gave me a hand putting some of it together and coming up with some ideas for the rest of the construction. The hardest parts are almost over. As you can see the inside 45 degree pieces will help funnel the media under the work space grate down into that big hole withere the funnel will be built on the bottom of the box to recirculate the media into the system. Anyone who knows how to do crown molding knows how much of a pain in the ass it is to make all the compound miters! We put all those pieces in without a single recut! good shit!

The entire box is made of 3/4" particle board. outside dims are 48" wide, 41" tall and 31" deep. The inside will be skinned with some 1/16" sheet metal if when i use it the media starts to eat at the wood… we will see. The feet will have swivel casters with locking brakes. The front glass is 12" tall and 42" wide. Saftey glass with a lexan replaceable piece to protect the glass from being blasted. It will have a expanded steel work grate mounted inside the box to hold the projects while you blast them. Kit includes a electrical box all wired up and a switch to mount outside the box.

It will be heavy but it will also be solid thats for sure and a cab this size would cost you about $1000, so its a great deal and will work just fine.

Just about done. Yetti and I forgot out 7th grade math skills and it took a while to figure out how to make the pick up funnel on the bottom. lol And we accidently cut up the front cover piece i set aside, so i gotta make another one and mount the glass on it. We made a sweet trap door at the bottom and it fully opens without hitting the ground, and seals up like a champ with a nice latch system.

But there it is. All 6’ tall worth of mighty media blasting power.

The height is perfect. Very comfy to stand at and work inside. My adjustable shop chair is the tits too… perfect height to just chill in front and blast some metal. Or drink a beer.

Tonight I just have to put the last panel on, mount the glass, wire up the lights, and cut the side door in and frame that off. and it will be ready to blast!

It’s all finished.

Mounted the glass. Cut out the door out and framed in the jamb inside with some nice foam/rubber gasket. Found a brand new air filter from some car and used it for an air intake on the door. Just cut the door out and dropped in the filter, the gasket seats perfectly on the door. Then I cut out a frame and routered out a lip inside so it goes over and compresses the gasket on the filter to the wall, just like your airbox lid does.

I took a ¼” NPT nipple 1-3/4” long and sent it through the wall. Then sandwiched in some washers so the compressor fitting and the coupler inside to attach the hose tighten up and seal to the box. That made a perfect air attachment point.

The kit came with a prewired electrical box. The box plugs in an outlet. Flip the switch to on, and that energizes the outlet on the box so you can run your vacuum and the inside light from the switch. The inside light is mounted to a 1” dia threaded shaft that gets sent through the box and the light socket mounts to that inside and seals up the box nice. I have a 150W flood light inside, and its BRIGHT!!! I also wired the florescent light above the work area, up so it comes on with the switch being OFF. That way while you’re blasting you don’t get the reflection on the window from the light above. Then when you shut the blaster off the light comes on and you can see inside to take the work in and out.

I welded up a nice work grate too. $50 worth of metal from Metal Supermarket. Used expanded steel 1/8” thick for the grate, ad 1” square tube 1/8th wall for the frame, all tigged to perfection. Its held in the box by 50 1-1/2” long #10 self tappers with big washers under the heads drilled through the box all the way around. It will support my weight in side there, I tested it!

So here it is…

I shot Yetti’s centers with it for a little bit last night. It works very well! But I need to get another bag of walnut shells casue I only had about 15lbs left from last year. The 33gal compressor is a little small for it, so I have to wait between cycles but it gets the job done at this point. I also used some of the 1st choice media I got with it. Not as aggressive as nut shells, so it doesn’t really take the paint off, but its fine and gets surface rust and stuff like that off parts like butter.

So far I like it, no leaks at all, I don’t even need to leave the vacuum on to use it, it doesn’t get dusty in there much at all. The gun needs some tweaks to still, the jets need to be adjusted, and the compressor doesn’t really have the balls it should for a setup this big but it’s a great start!