Well, I decided it was time to ditch all the old worn out bushings, bearings, tie rods & ball joints. I also wanted to rebuild both half shafts and clean up the diff while I was at it. And in my spare time so far, this is what I’ve come up with and completed so far

Rear Subframe before I got started…

After the Subframe was stripped and most of the flakey stuff off was knocked off (looks a tiny bit better, hah)

Had to remove all these inner sleeves from the Subframe, Arms and Spindles after removing all the Bushings… what a PITA! Its not exactly hard to do, but its very time consuming.

Then I decided to Box in the Traction & Toe arms.

After Boxing the above Arms I drilled some holes to stress releave things so they can flex a bit if need be rather then snap if it ever came down to that…

After doing the rear arms I thought I’d also do the Front Control Arms.

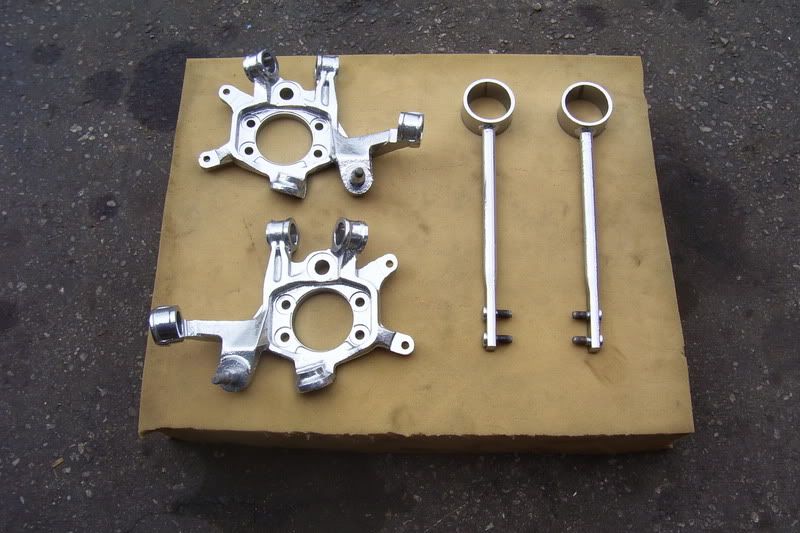

All the Arms, TC Rods & Rear Spindles all blasted and ready for Powder Coating

Here are some pictures of everything after I Powder Coated it all up. Subframe was done in a RAL3020 Red.

I also did a bit of boxing/bracing on the Subframe

Front/Rear Arms, Spindles and TC Rods were done in a color called Extreme Chrome.

Crappy shot of the Subframe with the Sway Bar (the Red on Chrome should look real nice once its all back together)

Energy Suspension Bushing all pressed into the TC Rods, Front Control Arms, Rear Arms and Rear Spindles.

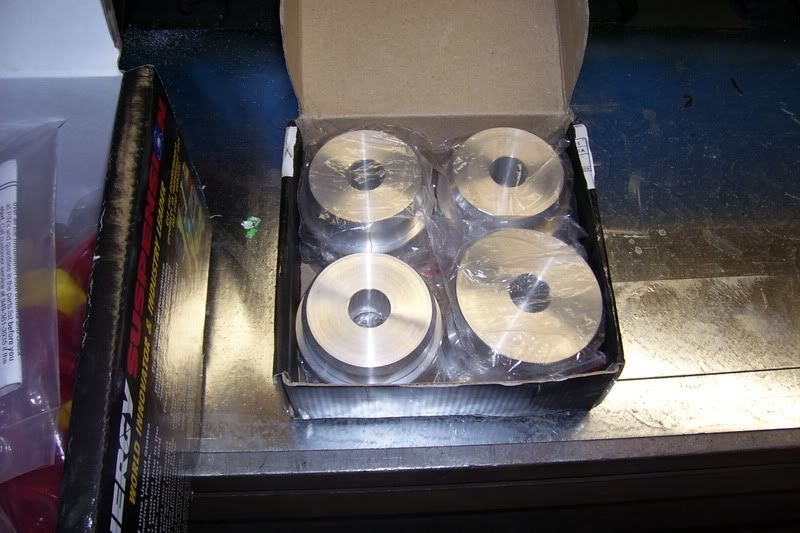

Solid Aluminum Bushings for the Subframe

Subframe Bushings all pressed in and ready to go

All the Bolts, Nuts and Washers from all the Arms/Rods/Spindles etc etc… Plan is to Media Blast them all and Coat them in a Flat Black as theirs no way Im putting everything back together with rusted hardware.

Most it all Media Blast and ready to be Painted

After being Painted

Next up is to Blast all this stuff and get it Coated up. Unfortunately I dont have spare rear Calipers thou so I will have to wait until I swap out everything in the rear and re-build the Calipers that are currently on the car.

Sad part is I still have quite a bit of work left to do…

- Press Hubs from Bearings (Buy new Bearings)

- Rebuild both Half Shalfs/Axles (Buy new Universial Joints)

- Buy and Install 4 Lower Ball Joints

- Powder Coat Diff Cover

- Prep & Paint Diff Housing

And that means I can start to re-assemble things in order to swap out everything with the parts that are currently on the car.