UPDATED [7/16/2010] The Final Chapter!!

Stages

- Prep/Clean Up

- Brakes/General Stuff

- Fixing the Wiper Gremlin!

- Interior Stuff - Vaders

- Subframe Replacement / Reinforcement Plates

- Wheels / Tires / Alignment

- Issues & Power of Community!

- The Final Chapter

NOTE: This thread reads backwards, meaning most recent stuff is at the top.

Stage 7 – The Final Chapter [UPDATED 7/16/2010]

After a year and a half of fun with this project, it’s time to write the final chapter.

So “Winter car use” was my number one justification for keeping this car as a 2nd car, but I know it’s just not necessary. The M3 sedan I bought last month is in decent shape, but it’s not like it can’t be driven in the winter. All I have to do is jack the suspension up, put on some 50 series snows and save up for a new front lip every winter!

In all seriousness though, keeping this car doesn’t jive with my philosophy to try and keep life simple and clutter free. I’ve been experiencing “complexity creep” in my life and feel like I need to simplify, cut things down, and make time for what’s important. So the 325i will be going up for sale.

Last time I checked though, faded three tone paint jobs and wheels that resemble bottlecap lids like

UGH 1

UGH 2

UGH 3

… tend to attract buyers who ask “will you take food stamps?” while asking about bus routes to come see the car.

So, I took some time to make some cosmetic updates.

The front bumper was scuffed, sanded, and sprayed black. I sourced a nice silver M3 sedan bumper and moldings and painted the M3 bumper black the same way.

The questionable grey lower skirts were masked off and blacked out as well.

(note awesome knife rip I made because I realized that when it’s taped up and masked off, you can’t open the door! DoH. Don’t worry I remasked it before actually painting)

I picked up a set of nice OEM 16" from a 328iC and threw some good RE92s on them too.

The M3 lux seats from my '97 sedan were swapped into the 325i to match the M3 rear bench in there.

Here’s a comparison while I had a Lux seat and Vader side to side:

In the end, the car didn’t come out half bad! Seems a shame to let it go… But I’ve made up my mind!

In the end, here’s what I learned from the ol’ E36:

- Older BMWs are neither a big hassle nor very expensive to maintain (*1)

- These things are for the most part, overbuilt. 17mm nuts for the seat rails, really!?

- The car has the right mix of technology / simplicity (*2)

- Did I mention they drive nice and have that nice solid feel to 'em?

(*1) When one has no shame and bothers every Shift member for the E36 question of the week while simultaneously lurking on Bimmerforums classifieds at every waking moment

(*2) In other words, it’s modern enough to go good and handle well yet free of gimmicky driver aids and other weight adders.

Much thanks to all who shared time/knowledge with me- it was a lot of fun and I learned a lot.

And to those who think they’ve escaped the Saturday morning “hey what’s up man, I’m trying to get this bolt off the Beemer’s _______ and…”

Don’t forget I still have an E36 (:ninja) so don’t deactivate the caller ID/blocking just yet!

Onward and upward! It’s been fun! :thumb

Stage 6 – Issues and the Power of Community

Calling this a “stage” is a bad joke, kind of like this vehicle. It’s more like “Mistake 6 – Issues and….”

Well, you have to give me credit for being unique here. For one thing, this is probably the only build thread where:

- Car has shiny bright and clean headlights

- Interior has been fixed up to some extent

- Car has rims/tires/major rear end work and good suspension

YET the engine bay still manages to look like:

Damn, this M50 looks like it spent New Year’s Eve at the Albany bus terminal with the head resting on the toilet.

I will continue to stand by my excuses that

- this is a daily so I don’t care what it looks like and

- the price of bread has gone up $0.32 and BoA does not finance Simple Green

This time, though, it turns out the lack of attention would come to bite me in the a$$… (Actually, after spending most of the holidays demolishing a 7 lb Honey Baked ham with my cousin Brian, a bite out of my a$$ may help me to look quite appealing)

Yes I know the visual imagery was just too much and some ladies out there had to take a cold shower. So dry yourselves off and read on (this totally did not sound good).

Now, let’s back things up a few days:

12/31/2009, 1:47 PM – Getting ready to head out to NH for the long New Year’s weekend. After piling about 7 bags, stroller, crib, etc into the family van, I’m feeling lazy to clean off the Beemer before I stick it into the garage. So I don’t. In it goes with about 6 inches of snow on the car.

1/1/2010, uh, all day – Most of the day is spent struggling to breath in between bites of Honey Baked Ham.

1/2/2010, 1145 AM - Somehow, Brian and I finish the ham after just 2 sittings, and decide that defrosting and roasting their turkey left over from T Day is a good idea – for, ah, FOUR people. So the rest of the weekend is spent in and out of food coma.

1/3/2010, 7:45 PM – Back in NY after driving through the snowstorm. My belly rubbing on the Odyssey steering wheel functioned as a sort of passive stability control mechanism and probably helped me save the van from a couple slides. Thanks Honey Baked Ham.

I get into the 325 to pull it out of the garage but all I got was-

WHRRWHRRRWHRRRRRWHRRRRRR just cranking, no firing.

I thought I heard it catch once or twice, but no more than a revolution or two and it just wouldn’t go.

I try it about 6 times, alternating between stepping on the gas and not, but it was as if the M50 is saying “not now, man, lemme sleep it off some more ok!?!”

Although this is my daily, I’m lucky in that my brother is out on vacation so I can use the Civic tomorrow to get to work. I’m tired, so I give up on trying to do anything more.

Monday morning: a couple of PMs from more knowledgeable Shift members later (oh wait, “more knowledgeable” could mean the entire forum so let me be more specific- thanks Fn Skanks and skiboard), I was armed with the following ideas:

- Turn off the sappy R&B and listen for fuel pump priming before starting

- Crank Position and/or Cam Position Sensor(s) could be bad (Yikes!!)

- Moisture from melted snow could have crept into the DME and screwed something up

- Moisture in tank could be bad enough that it’s affecting ability to start

- Pull coils / plugs and check for fuel delivery

Fn dropped by that evening to help check me out (and the car as well).

Before I could ask insightful troubleshooting questions such as “Yo does Bavarian have one V or two?”, the rear seat was apart and Fn was asking me to put it in RUN so he could listen for the pump.

We went through that and I checked fuse #18 under the hood and it all seemed legit.

While I cranked it, we could also smell fuel, so it seemed that fuel delivery wasn’t the issue. I had already checked around the DME and it was dry so I doubt it went bad (whew).

Soon, though, we find this:

Yuck. I could almost see the electrons slipping and sliding all over the place trying to jump the gap.

This called for cleanup of the coils, new plugs, and a new valve cover gasket to make sure it stayed oil free. I thanked Fn for help with the diagnosis and started piecing together the plan.

Next day, I order some parts from Union Foreign Auto in Ballston Spa.

Note: Good service there, the lady answering the phone really sounds like the band camp girl from American Pie. Dead serious.

Getting the valve cover off is easy- the hardest part is the bolt at the left rear of the engine.

But since I pack mad small tools getting in is never an issue (re-reading this sentence I realize why I never had any good game):

Removing bolt at the rear

JDM mallet that I used to tap out the GDM cover!

These spark plug seals actually cracked in pieces as I was removing them. Yep, I’m sure they were preventing all kinds of leaks in this condition!!

Coverless M50

I took a moment to congratulate myself on not dropping washers / nuts straight into the combustion chamber, then cleaned up the mating surfaces with gasket scraper and then put some Permatex on the front and rear of the head before laying the new Reinz valve cover on:

Then I replaced the old hardened up bolt washers

I went with NGK BKR6E’s for the plugs after reading BF.com.

Although these are supposed to be pre-gapped at 0.032”, I found mine were all at 0.036” so I adjusted the gap down before installing.

Another after pic

I also replaced the breather valve / O ring to prevent more leaks:

OK, so the moment of truth… Get into the car and crank it some more.

The engine catches a couple times but keeps dying. Hmmmm seemed to be getting closer but still not quite there.

I scratch my head and nuts (in that order, I think) and remember another PM where Skiboard told me to try and put HEET in the tank to remove moisture build up in the tank. Good thing I picked some up on the way home.

I put 2/3 of the HEET into the tank and go chill for awhile… Wait 25 minutes and about 5 attempts later I had:

YESSSSS! Got it started!

I had to give it gas to get it to start but after it ran for a minute I could take my foot of the pedal and it settled down to about 800 RPM eventually.

Just to be sure, I drove the car to the gas station and filled up the tank. Car felt smooth, no hesitation. Good for me.

So in the end, a problem that would have me stressed out about how to get to work turned into a pretty easy fix and great learning experience.

Thanks again to the E36 heads and cheers for the power of community!

:thumb

Stage 5 - Suspension / Wheels / Alignment

OK, time to get the rest of the suspension in the car.

First order of business - STRIP the top sway bar mounting bolt at 12 midnight before you need the car to go to work!

Again, the reason why I ask people for help!

Quick (non-booty) call to B-fizzle (my nizzle) and there is no endlink to be had for the late night emergency.

So I have to undo the bottom link and pull the strut out. I figure I’ll finish the job and just leave sway bar disconnected.

So I put the new struts in:

I couldn’t finish without sourcing sway bar link, so I drove to work without the sway bar connected and purchased the end links from Eeuroparts.com.

They are knowledgeable and parts always come the next day if they’re in stock since they are in Connecticut. Bought some Karlyn tie rods there too.

New tie rods were put in at Cooley Mazda, along with new sway bar end links:

Now that the pending issues from the installation are addressed, time to mount up the new (well, ok, used) shoes!

I chose to go with SSR Competitions, 17x8.

Main reason I went with these is that they weigh less than 15 lbs. Secondary reason is that they have a nice open look.

Tires are Sumitomo HTRZ IIIs, sized 225/45R17. So a pretty basic fitment. I’m not one to try and put playing cards between tires / fender, sorry.

SSR Competition Wheel

Stack o’ 17s!!

Anywhere Tire Care got the call to do the tire mounting, mainly because you can’t beat home mounting and he had mounted 245/40 18s on RPF1s for me before without scratching anything. Mike’s a nice guy and he knows what he’s doing. Doing a nice business for himself…

All mounted up but still too much of a rake… (We’ll have to fix that)

So yet another night burning the midnight oil and falling asleep at work the next day and:

I start with this:

Play with this:

And end up with:

Overall, the ride height is set to:

The last piece of it is a good alignment to

- make sure car goes straight when wheel is straight

- increase contact patch when the car is in turns

- set toe characteristics so there are no surprises

I brought the car to Capital Cities in Glenmont, a recommendation from BF.com.

It was obvious that they had done previous work on custom suspension setups and knew all the adjustments. A BF.com member had an alignment done there with TCK Single Adjustables, camber plates, and rear camber arms, and had good things to say. This was very similar to what I was going to have done.

I heard that SCCA guys use Watkins Spring in Albany, NY for a good alignment, but the pricing was almost the same and after talking to both places, it seemed that Cap Cities had more experience. Brad from Cap Cities is a great guy, very helpful and personable.

I had been to Cap Cities once, actually as part of the Craigslist deal in which I picked up the 3.38 LSD from one of their techs. He was there but busy so I could not say hi that morning. Brad said he remembered me though and asked if I put the diff in yet. Well, that’s Stage 7 I guess!!

Extra bonus is that I got a free recall fix, the radiator cap replacement from bringing my car there. Well, the extra cost of the alignment more than covered THAT, but it was nice to know even old ratty 17 year old cars get a break once in a while.

I asked for the following alignment specs:

FRONT

Camber: Negative 2.5 degrees

Caster: Positive 6.0 degrees

Toe: 0.0 degrees

REAR

Camber: Negative 2.5 degrees

Toe: 0.20 degrees total toe in (same as 12’, or 12 arc minutes)

As with any place, I got the printout the afternoon I picked it up.

At maximum the specs were off by 6’, or 6 arc minutes. One arc minute is 0.017 degrees, so this is about 0.1 degrees… Er, I think I can live with that!

No alignment write up is complete with the

GRATUITOUS BUTT SHOT!

Here you can see how the top of the tire leans in more to the center of the car.

And here you can see nothing about the alignment, thanks to my ghetto rigged rear bumper.

And last shot so you can see where this 325i started:

Overall, Cap Cities was definitely a good experience, as with most people who have learned some BIY (Butcher It Yourself) stuff, I tend to stay away from dealers since I’m a cheap a$$, but it’s nice to be treated well at one, with the job being done well and on time!

I was kept up to date with what was happening on the car and made to feel like my old POS mattered. That’s service! Or maybe just plain butt ki$$ing. Well, business revolves around customers, and you can peg me as a happy one for now.

Impressions:I went out for a drive Saturday early in the morning and within 5 minutes ended up here!

So the alignment is that good I guess!!

But seriously, with the suspension (and myself) set on Full Hard (minus half an inch, er turn) I bombed out on some local roads /on-off ramps this past Saturday morning.

I can feel the weight transfer of the car so much better and there is a feeling of quiet stability at higher speeds.

Turn in has been helped too, not only with settings but I’m sure the new tie rods contributed a lot here too.

There’s only some rubbing at full lock, but none while driving. Overall, very happy.

Stage Four – Suspension

[8/29/2009]

There are several known issues on this car with respect to the suspension / subframe, 85% of which are a pain to get at because it involves removing bushings!

My plan of attack to address common issues with the 325:

• Replace Rear Trailing Arm Bushing (RTAB) (2 pcs)

• Replace Ball Joints / Bushings in Rear TA (4 pcs total)

• Replace Ball Joint / Bushing in Upper / Lower Control Arm (link to subframe) (2 pcs)

• Replace Subframe Bushings (4 pcs total)

• Replace Front Differential Bushing (1 pc)

• Replace Rear Bearings (both sides)

• Replace Rear Hubs (both sides)

• Replace E-brake Shoes (both sides)

• Weld in Reinforcement Plates for Subframe Mounts

Now, the challenge

This car is my daily (hence the thread title), I don’t have a “beater” or second ride that I can freely use if it’s out of commission. So… This whole thing had to be completed in one day.

This required some advance planning on my part (and late nights in the sauna, er garage). Serious, I lost more weight sweating it out in there than going to the gym or attempting to run/jog/walk around Halfmoon, NY.

WARNING: This is a Mega Update and I am Mega Boring so grab a Mega 5 Hour Energy, Pop a Viagra, Experience a 5 Hour Boner and Read On!!!

I’ve split Part 4 into several steps(as if that helps people from falling asleep)

Step 1: Prepping

Step 2: Getting Parts

Step 3: Bearing Presswork

Step 4: Installation

Step 5: Aftermath

Step 1: Prepping

I figured that having a spare set of all parts would be necessary to prep / clean / check parts and most importantly have the darn bushings removed!

So I picked up:

’95 M3 subframe + Upper & Lower Control Arms + Loaded Trailing Arms

Checked subframe, it looked ok, bushings weren’t even half bad but I already made up my mind to go with Powerflex Polyurethane ones (the purple joints)

To start things off, I disassembled the caliper off the TAs, threw away the crap rotor left on ‘em, and proceeded to pull off the hubs so I could get at the bearing / Ebrake stuff.

Getting ready to pull hub

Ghetto Technique to retain leverage when pulling hub with no way to stop it from turning and you wear cheap New Balance 574s and are laughed at by opposite sex at clubs

More Ghetto Freestyle BizNeSs with Slide Hammer

Finally (!!@#@) Some progress!

This one is simply titled “101 Reasons the wife wants use of the garage back by Fall ‘09”

OK, in the meantime (and many nights sleeping on the couch or living room floor), I hatched up the next plan:

Step 2: Burn Up Credit Card On Mad Pricey Bavarian $hit

Ball Joints / Bushings and I$ht (not including Powerflex stuff)

E brake shoes

Rear Wheel Bearings

All Important Subframe Reinforcement Plates

Call it overkill, but I ended up buying a spare 325i rear axle too because one of the threads seemed FUBAR on the loaded trailing arm I got. I just could not afford to have anything missing that would seriously delay the project.

Basically, I wanted to COMPLETELY AVOID having to remove the axle/hub/collar nut etc on the assembly on my car, so I was building a completely new subframe with pretty much everything in it.

Having said that, the next thing you do is:

Step 3: Presswork i.e. Put Machine Shop Guy on Speed Dial (as you Bend Over)

In the meantime, I was busy becoming bum chums with the guys at the NAPA Machine Shop on Wolf Rd, seeing as I seemed to be dropping off parts every couple of days.

Basically, they did the bushing removal work and press work for me. One of the hubs from the loaded trailing arm I bought did not cooperate and come out easily so they got that out for me too.

I tried to go my tried but not true El Cheapo Route and buy a used hub from Bimmerforums.com off a pretty reputable seller there but got this in the mail after waiting a week for the damn thing:

Faaaaaaaaaa##@##$k!!

I got a refund eventually but wasted about 8 days waiting for this sad POS posing as a hub.

That $hite irked me to no end, so much so I whipped out the plastic again and dinged my Paypal account for some new hubs:

Man, why do them $hits gotta go UNDER the car, they are like the nicest thing on my vehicle!!

These joints are so pretty, if I had real neck muscles I’d wear one on a chain, like Flavor Flav does with clocks and $#ite…

Anyways, I digress (my specialty, I know).

After a couple of days, NAPA pressed in new bushing/ball joints into the trailing arms and put in the new bearing / snap ring and pressed it with the hub. I ended up with:

Side note: I did take all this stuff to Hunt’s Machine Shop in Schenectady, but after I asked for a quote the guy looked at me like I asked him for his digits at the Blue Oyster Bar… He went on and on about how it could take HOURS to get that hub out and he wouldn’t want to charge me like $300 if it took way longer than I thought.

In the end, I figured he didn’t want the job so I just threw my stuff in the car and left.

Basically, I think he was pricing himself out of it since he didn’t want to touch these ghetto fabulous used parts. Heck, if I had a reputable business, I probably wouldn’t either. But NAPA was all good with it, so they got the work! Hey I understand building engines / precision machining is where the $$$ and props are at but you want business during these times, you gotta do dirty work too ya know?

Soon I had more components disassembled and brought these to a buddy who does some ill sandblasting work. And when I say ill, I mean he was doing blasting prepping salt trucks and stuff for the State, so the following parts were literally a drop in the bucket.

Approximately $160 of press work and a few million particles of abrasive resin later I had:

I also threw in some extra parts to get blasted, such as the 3.38 Limited Slip Diff I picked up off a ’97 M3 and the X Brace I bought from Bimmerforums.com:

Once I had the loaded trailing arms done up with the bearings/hubs, I was pretty much on easy street. Only things left to do to complete the preparation were:

Masking parts for painting, followed by:

Painting new components!! (Yes I eventually did the X Brace too)

Now that everything was ready it’s time for:

Step 4: Installation aka MAAD #@@# WeRk, SoN!! [Updated 9/16/2009]

Time to get busy and install these parts that were just sitting pretty in the garage!!

8:40 AM

I pull into Wayne’s spot in good ol’ D-burg (home of Stewarts and uh, that’s about it for downtown).

Entering Wayne’s World, aka home of D-burg’s Welder Supreme

Wasting no time, our man has the car up on stands and is working exhaust bolts before I can say “yo who jizzed under my rotor?”

An overview of the work area (Caddy motor and auto tranny not going in today- sorry)

Soon the exhaust is off and lower shock bolts are removed. Calipers are removed from the mounting bolts and ziptied away from the rest of the subframe. Wayne removed the driveshaft to diff bolts as well, probably the trickiest part of the job but he zipped through it pretty easily.

We pull back the wheel speed sensors for the ABS and the brake pad sensor on the right side and within about 1.5 hrs of jacking the car up, we are ready to drop the subframe out.

Note: you can’t see it well below, but if you put the jack 1-2 inches behind the BMW symbol on the side of the differential, it’s pretty much the center of mass and allows you to drop the subframe down without it tilting and crushing your body parts.

First the subframe wanted to hang up, so we thought it wasn’t coming down straight. But obviously THIS was causing problems:

ILL a$$ cracking around the passenger side front stud that hangs down and functions as 1 of 4 subframe bolting points.

No WONDER the car was starting to exhibit iffy handling and feel like $hite…

I seriously question why BMW allowed the chassis engineer to use a stud bolt design that acts as a cantilever beam that is basically cyclically stressed over the life of the car.

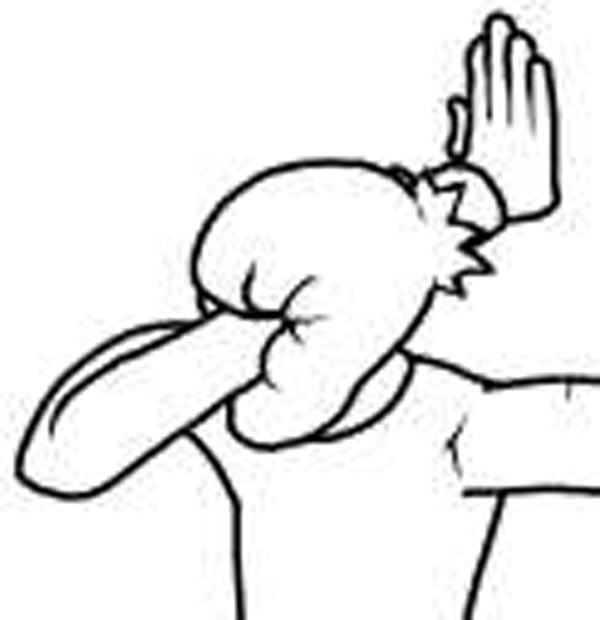

This type of ill shenanigan deserves a straight through facepalm, just the like the stud bolt causing tearing through the chassis…

Ever the optimist, I think of the upsides:

(1) The OEM reinforcement plates from Turner Motorsport fit like a charm

(2) The crack didn’t go all the way around and cause me to have a major accident

(3) I know the rear will be good for pretty much anything I throw at it after the weld reinforcement

(4) My wiener schnitzel is still above average in girth, regardless

Proof I’m not just pulling your leg and (1) above is true:

As for (2), you can see much more clearly the extent of cracking after the area was cleaned and prepped by “Da Man”

As for (3) and (4), well you’ll have to take my word for those.

In the meantime, Wayne got to work under the car and performed the hard-core cleaning and prepping the four areas where plates would be welded, followed by the actual welding of the plates to the underbody.

I did the easy stuff and started assembling the new subframe / control arms and transferring parts over to the new unit:

See the old subframe at the bottom, new one being worked on at the top!

The Powerflex urethane subframe bushings were really a nice fit and went in real smooth.

Meanwhile, the UUC Rear Trailing Arm Bushings (RTABs) had a crappy a$$ fit- loose as hell and they made me think of the mother in the show “18 Children and Counting”. Damn.

These look decent but fit so poorly in the trailing arm they will actually fall out if not held in with the bolts when mounted. You can even see in the photo they’re loose… I plan to replace these with Powerflex units in the future.

Over on the other side of the massive two car garage, Wayne is getting real busy with some ReAL WorK (SoN!)

Grinding / Prepping Plates for a nice weld job

Kickin’ a$$ with some proper welds

Spray painting the underbody for rust protection

Looking nice! Big thanks to Wayne, seriously…

I got under the car to admire the handiwork, then returned to my subframe(s) to do what I do best and butcher stuff:

“Oh so the ABS sensor is supposed to come out as one piece you say?”

Some stuff even a moron can do, like match the lengths of the adjustable rear arms to the stock piece (at least until this sucker is aligned properly). So I hit that… I went with SPC rear camber arms, by the way.

Mounting the trailing arms onto the subframe (note rear sway bar was transferred over from the old subframe as well). I will be running stock M3 front sway bar with stock rear sway for the time being.

Sway bar goes in, other trailing arm is assembled, we torque down all the nuts and bolts to Bentley specs and the entire subframe is almost ready to put back into the 325!

The red / gold things in the upper control arm are the adjustable perches for the suspension (Ground Control / Koni w/ Eibach Springs, basically a run-of-the-mill full GC kit).

Getting there!

Wayne moving the creeper so my clumsy a$$ doesn’t accidentally use it as a skateboard in his garage.

NOTE: If you are a sharp guy, you’ll notice the old LSD went into the subframe.

Well, apparently the output flanges (diff to axles) are a different size from non-M to M.

(LSD was from a ’97 M3 so it works with larger axles). I didn’t realize how easy it was to swap the output flanges- thought it would be much more work than it actually is- so I kept the stock 3.15 LSD for now. Will be putting in the 3.38 LSD at a later date though!

Stock rear struts vs. Koni adjustables

Getting the subframe into the car wasn’t bad at all. The trick was to balance it and jiggle around towards the front where it tended to “hang” more with those long a$$ studs coming down for the front mounts.

Subframe in and bolts torqued up = only exhaust left!

Wayne put the exhaust in pretty much by himself- still going strong even though it was about 10:30 PM at this point. I handed him tools and otherwise pretended to assist.

We only had two breaks the entire day, 30 min for a quick run to Dunkin Donuts at noon, and took about 1 hr to go in and eat a killer burger from the local D-burg spot while watching some Speed TV on the big screen. So, yes, WoRk was done today.

11:00 PM

We finally set the car down after a 14+ hour day…

Not wanting to leave anything to chance, our man took the car for a quick drive and he pointed out the following – all after a quick 5 minute turn at the wheel.

(1) Left tie rod was loose and a quick pull on the front wheel at 3 and 9 o clock confirmed something was up with it. Put it on my to-do list for replacement.

(2) Main bolt on stock front strut was loose (we ran out of time to put new front struts on so the old ones off a ’99 M3 were left on the car for now) - ILL! Wayne hit it with an impact gun and that issue was solved. Props! :thumb

(3) There is a loud clunk from the rear of the car (on both sides) when going over a small bump at low speed. After having double checked all the suspension components, we concluded it was the RTAB. A quick visit to bimmerforums.com yielded a couple of threads on this- basically it’s not uncommon and probably a result of the poor fit with the UUC piece and not using marine lube on it. Will update if it goes away after I replace the RTABs with Powerflex pieces.

(4) My front tires were WAY worn on the inner edge, likely a result of crap alignment and also negative camber after installing M3 struts/springs that lowered the car and scrubbed tires that were probably toed in/out/who knows!? I made it a point to throw on my winter set with good tread immediately.

Overall Impressions

Well the car look, felt, and drove like a bucket of shiz when I pulled into the driveway that morning, and after the repair the rear was definitely much more planted. I swear, a horse carriage with a single transverse leaf spring had more stability at speed than what I rolled in with.

As I drove to D-burg that morning, doing a killer 40 mph on the highway, I was fiddling with the wheel to keep the car straight- probably a result of all the play in the subframe with relationship to the body. Since the trailing arms and control arms were connected to the subframe, they moved too and caused all the issues.

At one point I seriously thought about calling AAA and getting it towed, the car felt so bad.

Although the front suspension was not yet installed at this point and it was not yet aligned, the difference was already huge and well worth the effort, time, and money spent.

Step 5: Aftermath

Lessons Learned

• Source subframe and control arms separately to have the bushings removed ahead of time. If not, what took a long a$$ day will take you MUCH longer.

• If you are not going to replace wheel bearings as I did, skip sourcing a set of trailing arms and buying the other stuff like hubs, etc. But hey, if your car has 130k+ on it and bearings go… Ya missed your chance to do it and it’s gonna cost ya!

• When lowering the subframe, make sure you are lowering the subframe at its CG (center of gravity, or center of mass). For the entire subframe assembly, the CG appears to be about 2 inches to the rear of where the BMW logo is on the side of your diff, below the output flanges.

• If the subframe is coming out but seems “stuck” on the front studs, don’t force it to come out unless you are sure it’s coming down vertically and not bending the stud. If you continue lowering it and it’s not straight, the moment created at the stud to underbody interface (remember “cantilever beam”?) MAY cause even more damage to what may be cracking around the front subframe mounts.

• Cleaning / Grinding / Prep takes MUCH longer than actual welding for the plates.

• If your welder / assistant / BFF / Homey Lover Friend doesn’t know what he / she is doing, do not pass go do not collect $200 go to someone who does.

• Welding the reinforcement plates is a balance between joining enough of the metal to make it sturdy but not welding so much that the metal is heated and weakened as a result.

• Replacement plates are a great fit – BUY

• Powerflex Bushings are a great fit – BUY

• UUC Bushings are a sucky fit – POO

• 3.38 Diff from an M3 will go into a non-M and all you have to do is remove the output flange (to axles) and swap them with the 325i pieces. The 4 bolt input flange (from driveshaft) actually matches up.Again, I didn’t realize how easy this was due to fatigue / trying to get things done that day, but using the trick in this video you can remove them WAAAY easy:

- Lots of negative camber with poor alignment will turn your tires’ inner edges to garbage. Mine were worn to the cords, literally, though they looked fine outside. So get that damn alignment already!!

Stage Three – Interior Stuff

[8/1/2009]

I’ve had the car for almost six months now and have purchased seats and cleaned it up a bit. Big wow, I know, but hey it’s hard to juggle other priorities with this stuff.

I finally got around to doing the window regulator / door panel though. Lemme tell you, the regulator is a PITA for two reasons: For one, BMW chose to curse all ’92-’93 E36 owners by integrating the motor / switching mechanism with the damn window regulator module, all to allow “easy one-touch operation”.

Personally, I don’t think any “one-touch operation” is worth $320, but that’s what parts stores wanted for a new unit. Forget that.

Fortunately, Ebay came to the rescue, and after ordering like 2 other regulators that were from a ’94 and ’95 and did not match up with what I needed, I finally wised up and checked realoem.com for the real deal Holyfield parts number.

Anyways, $110 and a esnipe type bid later, I had this:

Come on, would you pay $300+ for this piece of dung?

To make matters worse, BMW decided it would be a stellar move to include four rivets to mount this piece to the door panel. Brilliant.

After much finangling (yes, a technical term), cursing, broken drill bits, and one trip to Lowe’s for some funny looking pliers while I held in a monster dump, I removed all the rivets:

Exhibit A: Proof that Rivets > Cr-Mo drill bits

Note to Boeing: Use BMW’s Rivets in your 787, it should help extend those inspection intervals to like, 53 years!

Exhibit B: What your 325i looks like when parked in Jersey City for 2 hrs (note interior wipes can stuffed inside door panel to hold up the window)

Exhibit C: Funny a$$ pliers that did WORK!

Now I had to deal with a crack in the regulator that I stayed up half the night bidding for. Eff!!

BIG thanks to Wayne for helping a brother out at midnight though and welding it for me!! Little did he know he would be helping with a $hit ton more welding… See next phase: Subframe repair!! Hehe.

Couple of hours later, I managed to align the window with the tracks in the door itself while getting the regulator to move smoothly up and down.

I lost about 310 calories in the damn fitment process and had little energy to take pics, so basically you are left with the finished product, Voila!

[7/6/2009]

It’s been awhile but I have been busy trying to GET DIS MONEY.

The massively ripped driver’s seat that came with the car was cool in the sense that I didn’t feel guilty ripping huge ones into it after those late night jaunts to Taco Hell. (Oh wait, don’t I have a For Sale ad up on here?)

But what I really wanted was a seat that looked like it belonged in the car. And more support. Not just loving car guy support from the Shift518 members who are always there to keep me from picking up dudes because I owned a Miata for over two years- but true lumbar and lateral support as well!

Now, having said that, I wanted to stay under the budget.

“The budget” meaning, say $350 for a pair of seats?

Choice #1: Buy sliders for the Corbeau FX seats from my Miata

Choice #2: Buy some reclining “Sports Seats” from EGay?

Choice #3: Get a real job and drum up more than $350?

Choice #4: Hit BF.com. Go to Interior/Exterior. Buy Vaderzzz!~!

Choice #1 was ruled out mainly because I felt the Corbeaus were a trying a little too hard on this car. Fixed back seats on a daily driven car didn’t seem right.

I’m sure the wife would bust my a$$ too the first time she tries to recline it and reaches for the magical lever that is still at the Corbeau factory…

“WHAT@#! What do you mean they don’t lean back!?? #@#% Buy me a purse!!” So…

Choice #2 is great, but I could not find any good reclining seats for $350 including sliders.

Beggars can’t be choosers, I know, and I will totally cheap out on some things, but seats and safety is not one of them. So Corboo and Recardo did not get the Buy It Now straight from Pudong.

Incidentally, Sparco does have some real cheap a$$ reclining seats called the Steel but on the real, they reminded me of a limp flaccid you know what so I was like “nah”. Not looking real supportive. What do you think?

Come on, do these ^^ really look like they’ll do a good job!? Instead of Steel, they should rename it Sparco Flaccidity. And that’s real.

Choice #3 would be awesome, except I have little marketable talent aside from the ability to blabber for days, 1% of it relevant or likely to keep you awake.

This left me with Choice #4, so the search was on for some black leather Vaders out of the E36 M3.

I’ve sat in these seats many different times and they seemed to fit the bill for the three Bs in this case:

Build (fat a$$ is comfy up in there)

Bolstering (not aggressive but sufficient), and

Budget (y’all know what this is).

NOTE: The magical mythical fourth B (Ballerific) is still something I am trying to attain, but once I am able to make a dollar out of 15 cents- I’ll write about it.

Plus they recline. I lose the seat heaters, but last time I checked my Physics book, Q (heat) does not appear in the formula for lateral acceleration. So that’s ok.

Only con is that the Vaders seem to weigh MORE than the factory seats.

So much so that in preparation for the install, I actually spent the past 3 weeks at the Y squatting, doing deadlifts, you know, training up.

And being laughed at by young punks from Shen who picked up the bar off me and curled it in front of me- highly embarrassing when I just used it to bench press for reps.

But anyways, here are pics of the install!

Out with the Old

Vaders vs. Stock 325i seats

Installed

Other Comments

No modification is necessary to mount E36 Vader seats into a 325i (sedan).

All bolt holes lined up, and even a butterfingers like me was able to do the install. Again, be sure to lift weights and train up accordingly if you are the guy who gets sand kicked in his face at the playground.

Overall, I’m real happy with them.

Look for more work being done on this car over the next few weeks.

Stage Two – Fixing the Wiper Gremlin!!

[3/7/2009]

I got tired of driving around with my “fully manual” wipers this week.

Before you diss me, please understand that I am not one of the spoiled bourgeois b#$ches floating to work on air suspension, soaking in the tunes from the Harmon Kardon as I curse the rain-sensing wipers for malfunctioning.

No, “fully manual” means that I have to stop the car, get out, pop the hood, and replace the #36 relay in the black box next to the master cylinder.

Just to be able to wipe the windshield. Damn, wiping my own a$$ after dining at Great Panda Buffet takes fewer steps.

A quick perusal of BF.com (Bimmerforums, not ButtFest.com, don’t ask) told me that the problem is likely the wiper relay, or the wiper switch.

I closed my eyes and tried to conjure up images of electrical circuits from my circuits classes. What could it be?

Hmm Kirchoff (rhymes with jerk-off so I remember) had some circuit laws. V equals I times R… And uh, that’s about it.

Left to my own devices, I snapped the wishbone off of the Popeye’s chicken wing in my hand. Since the right one was longer, this undoubtedly meant it was the wiper relay.

Thanks to “Buy It Now”, the relay arrived at my house within 3 days. The package was wrapped up well and much larger than I thought… Wow I wish girls said that about me!

When I say arrived, I mean the package ARRIVED. Whoa, the wiper relay is about the size of two iPhones back to back, without the cool touch pad.

Here is the old (black) vs. new (white) relay.

(I know you STILL can’t see how big/small it is but imagine two iPhones in the photo- I’m still trying to “do the damn thing” so I don’t have one- try someone more ghetto fabulous sorry)

Sadly, the relay DOES cost about as much as a month of iPhone minutes+data plan if purchased at BMW, though.

The Bentley Manual and a couple of threads say that the E36 wiper relay is behind the glovebox so I promptly tear into that first.

Ten minutes later, this is looking like the fastest relay switch ever. Straight butta…

Butta nothin’!

Crud, it’s just a mess of wires and what looks like a cable box, but no relay. It figures.

If you look carefully, you can see how the relay would go into one of the black brackets below. (I put the new white relay box there to show this, it did not magically appear)

By the way, the big black box is the security module, ripe for the taking. Gee, I hope Esurance doesn’t read this thread.

I dig around more on the internet and find out that the next likely position is…

Under the dead pedal… Whaaa-whaa-whaaat!?

Why of course, it’s a prime location- the carpet soaks up moisture, and the lack of circulation creates a massively corrosive environment for the electronics! Way to go Bavarian Boys! (Insert golf clap here)

Ok, now I am thoroughly convinced that the relay box location was the result of miscommunication at BMW Gmbh.

Here is what happened.

English Intern: Herr Schmidt, we have finished the instrument panel and the glovebox design. The fuses are in place but alas, there is no space for the relay.

Schmidt: Bitte?

Intern: Let’s place it with the other fuses, shall we sir?

Schmidt: (Puts down bottle of Pils) Ja… Ja wohl! Mit dem FuB!! (Note: B = ss for the GDM tech whores)

Intern: Very well sir. (Gives instructions to Udo, the designer)

Naturally, our boy Udo whips out the Unigraphics and draws a beautiful over-engineered bracket under the dead pedal after confusing “fuse” with “FuB” (German for foot, as in FuBball).

Back to the thread.

After removing the dead pedal, here’s what things look like.

There’s actually a speaker in here too? Cool.

The wiper relay is the black box above the large white connector, at the center of the picture.

I swap out my new white one in its place.

I put the panels back in and connect up the battery. I put the key into ACC, and the wipers stay off. Good sign. Flipping through the varying speeds, it seems that the relay switch did the job.

Thanks Popeye.

[3/1/2009]

OK, this technically belongs in the “cleaning” section but I figured I’d post it in chronological order…

We finally took the car in for a wash.

BEFORE

AFTER

Cleaned up nicely for now!

To follow: More maintenance (cooling stuff, diff fluid, tranny fluid, plugs etc) and hopefully a fix for the “wiper gremlin”

Stage One – Brakes

In order to reduce the braking distance from bus lengths to car lengths, brakes are first on the list because they are a necessity from a safety standpoint. The pedal pulses like crazy on low speed stops, so time for rotors and pads all around, followed by a good flush.

The hardest use this car will see, aside from my daily 5.7 mph turn into the driveway, is a possible AutoX or two. However, as track nuts on this site (no names, though JClark comes to mind) have already explained elsewhere on this wonderful site, neither of these uses warrants a good set of rotors / pads / brakes anyways.

Soooo. Let us BE CHEAP.

$211 later, I have Wearever Rotors, Pads, Brake Fluid, and other random bits ordered up from Advanced Auto Parts.

Finally ready to make the trip to the RPI shop and take full advantage of the lift.

I figure, if I use the lift 7,328 times this year, it will make up for the cost of one credit hour at this hallowed institution of higher learning, where Red Dog and Bacardi 151 help to take away the pain of constant blue balls that young engineers experience through repeated attendance at sausage fest fraternity parties.

[2/26/2009]

All that being said, I ditch work early on a Thursday and pull the car into the RPI bay. My baller Sleeptracker watch reads 5:11 PM.

5:19 PM - all access baby! Lifts rock!!

The undercarriage actually doesn’t look that bad, considering the past few years this car has spent in NY.

The brakes need work though!

Rears resemble pizza pie with Martian crust

40 minutes into the job, I’ve got the front brakes off.

I’m on a huuuuuuge roll… And then…

What’s wrong with this picture!?

E36s have FIVE lugs! Advanced Auto Parts screwed me and ordered what looks like brake rotors for E30s (with four lugs). I check the rear rotors and it’s the same story.

And the car is still sitting on the lift with four rotors with Mars-like reddish surfaces. Now what?

A few quick phone calls later, I source a pair of fronts from good ol’ Autozone in East Greenbush. I excuse myself from the shop and the Miata and I make the run and get the goods (stupid Advanced #$@#).

Now I’m back in the shop, it’s 8:09 PM, and I’m hungry… But I have my rotors!

New vs. Old

The fronts were pretty straightforward, although I did get stuck for a few minutes trying to figure out how to pull out the pad wear sensor. Apparently, it just pulls out right of the pad from the top.

Good thing it was only the on the left wheel. Interesting, I guess the computer assumes they wear evenly.

Here’s the new equipment.

(You can catch my sweet two toned bumper too in this shot)

The shop is set to close to 9:00 PM but I’m able to stay a few minutes after and finish up the fronts for tonight. I couldn’t source the rears anywhere but will be putting those on and flushing after I get them (and get my money back from that Asinine Auto Parts!)

And now… A gratuitous shot of the stock E36 full dual exhaust.

Dual Dragger THIS b#$@es! (Insert Euro snobbery here)

Oh yeah… Turning the right rear wheel forward confirmed that this Beemer does indeed have the factory LSD.

Now I can turn into the driveway 6.7 mph…

Hellz yeah!

Stage Zero – Cleanup (Continued)

[2/23/2009]

After unearthing a couple of rats nests and a few more dollars in change (including several bills under the driver’s seat), my brother and I hit Night Moves with a passion…

Oh, and the BMW started looking a bit nicer.

My bro picked up some $25 floor mats at Target and proceeded to use the old mats as a template.

Once again, this is the SECOND step in prepping your car for serious track duty, AFTER headlights.

Do NOT try this at home, you have been warned.

17 Years of Bavarian Hotness =

$25 of Target Flava

Layin’ it Over

The new mats

New mats really helped hold my feet in place during high G cornering! Two thumbs up (my a$$ for this lie)!!

Stage Zero - Cleanup

[2/21/2009]

We started some light cleanup of the interior today. You can see the general condition of the car. When it’s light out I’ll take more photos as things progress.

Front shot

Pop quiz hotshot- what’s the first thing you do when you get your beat up car home? Why, clean the headlights of course!? Way cooler than doing actual work!! Note difference though from left and right headlights.

More cleaning…

Engine bay, pretty bad but not as bad as I thought…

Other interior niceties

More exterior pics

Trunk

Interior

The previous owner was going for the “Time Attack” theme in his buildup, but somehow confused the tuning philosophy and went with “Theft Recovery” instead:

More pics

Steelie (Thanks Pete)

Other wheels

This Roundel has seen better days

Carpet Pics

The Pickup

[2/20/09]

We left at 4:15 AM on Friday morning, made it to Long Island by 8:15 AM.

Our handy Civic didn’t have the juice to jump start the stock battery, so it’s good we had a spare one that I recharged. After swapping the old one out, the car started up on the first try and idled well.

After letting it run for a few minutes, I shut the engine off and we put the steelie that I borrowed of Fn Skanks on the rear left to replace the tire that went flat over the time the car sat.

We threw out crazy amounts of the previous owner’s shizza into a big GLAD bag and were out by about 9:30 AM.

He left so much junk in there it was obvious he didn’t care much for keeping things tidy. The upside? There was $14.50 in change in the car (which went, uh, about half way towards covering the sales tax).

A few minutes later, I put the plates and registration sticker on and we were in business!

Gas gauge showed 1/2 a tank but you never know if it’s true- so first stop was the gas station… Couldn’t figure out how to open the gas cap to fill up the shiznit.

Turns out there is an actuator behind the gas flap, you have to pop out an interior panel to get at it manually.

It wouldn’t open at first since I think the actuator rod was not connected.

Well, eventually I called up Pete, he helped me figure it out and I got the flap open.

Man, why did the Germans have to make it so complicated (and make me feel stupid?)

Warum!?!

Filled it up with 93, supposedly these cars need premium!? Ahh who knows, it’s not like the timing is advanced or it’s super high compression but what the hell I’ll be a big spender for now!

So first thing I notice is the clutch is heavier than my Miata (well even a lawnmower clutch is so scratch that useless bit of info).

Clutch take up is high off the floor, the car actually drove very smoothly and better than I expected.

(Translation: I stalled the b$tch going out of an already downward sloping driveway, and on the way home it did not randomly explode into a ball of fire on I-87).

But seriously, the brakes are shot and I’m sure the shocks are blown.

As I navigated multiple on-off ramps thanks the serpentine maze of highways that envelop Queens/BX, I noticed that the steering feel and overall balance really felt nice, much better than should be expected from a 17 year old car that was left for dead in someone’s driveway.

Thirty minutes into the drive, while navigating a 30 mph roundabout on 3 worn Michelins and a no-name studded snow at the rear left, I realized the potential of this platform.

Up to now, the only E36s I’ve driven are the M3 variants. These are impressive handling cars and everyone knows this- but driving the 325i for the first time I saw how that the base has performance DNA built into its character.

Now I can understand how the E36 M3s sold for a reasonable $36k when they first came out here in the US.

BMW didn’t have to do a whole lot with the base chassis- careful selection of suspension components, uprated tires/brakes really brought to life a chassis that could already more than handle the power of the S50.

(I know, I know, the Stateside M3 was not blessed with the high RPM breathing capability and big power of the Euro 3.0, but that’s a story for another day)

Back to my thoughts on the car- there was no hesitation at all on acceleration, each gear engaged smoothly with no grinds / noises.

I had to pull a couple full turns lock to lock to maneuver out the parking lot and didn’t hear any ugly noises or clunks. This was very good.

Everything seemed to work inside, heat, defrost, power windows. Sunroof seemed stuck though. Driver door panel is completely messed up for now though so I was not able to adjust power mirrors.

Not sure about A/C but the compressor does work when you turn it on. Might need a charge, wouldn’t be surprised- it’s a 92 after all.

Brakes are a different story. Even stopping from 30, they pulsated, shook the wheel, and made some nasty noises. So basically I did the whole drive home about 5 bus lengths behind whatever was in front of me.

During the drive, the coolant temp was completely normal and stayed there. The OBC showed an exterior temp of -35 F.

Double checking the next sign to make sure it said “Whitestone Bridge” and not “Welcome to Fairbanks Alaska”, I thus concluded the sensors no longer functioned properly.

I was momentarily interrupted by a $hitty Chevy Blazer pulling within my mandatory five bus length safety zone, meaning that I had to move over a lane to the left. My hand instinctively reached for the shifter…

The old neurons started firing and then… WAIT there’s no need to downshift, this thing has torque! And even a bit of horsepower too!!

My brain had forgotten that it is indeed possible to pass a moving object on a highway without downshifting into like, 3rd.

A year of Miata ownership has this effect on a person.

After passing Kingston NY I grew a sack and brought the 325 up to 90 mph for a very short stretch (fearing the four football field stopping distance more than an actual ticket).

Fortunately, there was no vibration or weird business.

The only weird moment driving up - the wipers randomly turned on for about 3 minutes. I didn’t touch a thing. I tried to turn them off but putting the stalk in the normal position did nothing. They went off again though by themselves.

Five minutes from home, it happened again, but they only went on for 20 seconds. Electrical gremlins!? Oh well, it wouldn’t be an older Euro car without these weird issues I guess.

By 1:32 PM, I was back in Clifton Park, smile on my face with visions of M suspension bits and engine swaps dancing in my head. However, in order to stay true to this “build” this will all remain a fantasy.

We shall see!