Hummmm good point! Have then been weak points?

wrist pins are always a weak point at 350+, might have to be custom machined not sure who makes an aftermarket repkacement, you should still think about o-ringing the block and using a one piece copper headgasket and running 35+ pounds of boost.

Damn it that edit button is too close to quote.

sorry guys

well considering youre gunning for 600+ whp im sure that could be an issue. i mean look what happened with Aarons car engines.

and like tom is saying o-ringing might be a good idea, although a smaller turbo, i ran 28-29psi without an issue on my setup. the OEM MLS head gasket hasnt really shown much issue in the high power world though. alot of 500-550whp cars are using OEM gaskets, with ARP studs(and stock TTY Bolts before the ARP hardware was available)

you have the Ie H-beams, many say the limits of the H beam rod in a 1.8t is 500-550whp. then you should plan around an I beam rod, like the Pauter, Brute I beam, or IE Tuscan rod.

ARP 625 bolts are recommended as well, not the ARP 2000s.

id like to NOT see this motor let loose and see it be a success. just gotta make sure everything is up to snuff.

There is still a good amount of fabrication to do on the car. The motor will hole 400-450 for ever, so that’s my initial goal to start. Make some passes, work the bugs out of the rest of the car then crank it up. At that point it wouldn’t be hard to drop the oil pan and crank then swap out the rods and bearings again. at that point I would like to have designed or bought a main bearing girdle too for extra insurance.

Also thanks for the kind words, coming from you that means a lot actually! Thanks buddy. :thumbup

I am not sure if you have seen this:

http://forums.vwvortex.com/showthread.php?4338034-My-VR6-MRIM-progress-thread…

That has been friend Lee’s science project for a number of years.

is lee EVER going to finish that car? i know jesse has done alot of fab work for him.

i see its close, but man its been SO long. i cant wait to see it put some power down finally.

Good stuff, I am reading through it now. CNC machine > hand grinding.

I should have the plenum cut the way I want it tonight and weld it back up too.

you gonna blow the welds off your intake!

probably so! lol Hope I got good penetration with those welds!

was the penetration deep?

I can go sooo deep… :number1

Annnd boom goes the dynamite

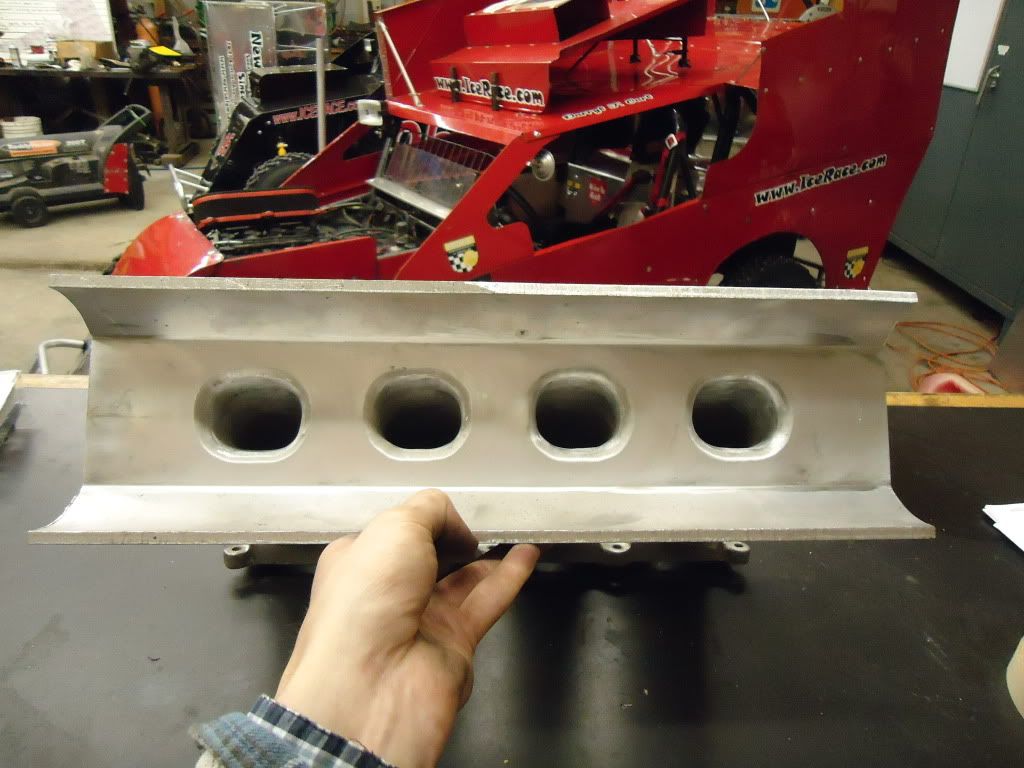

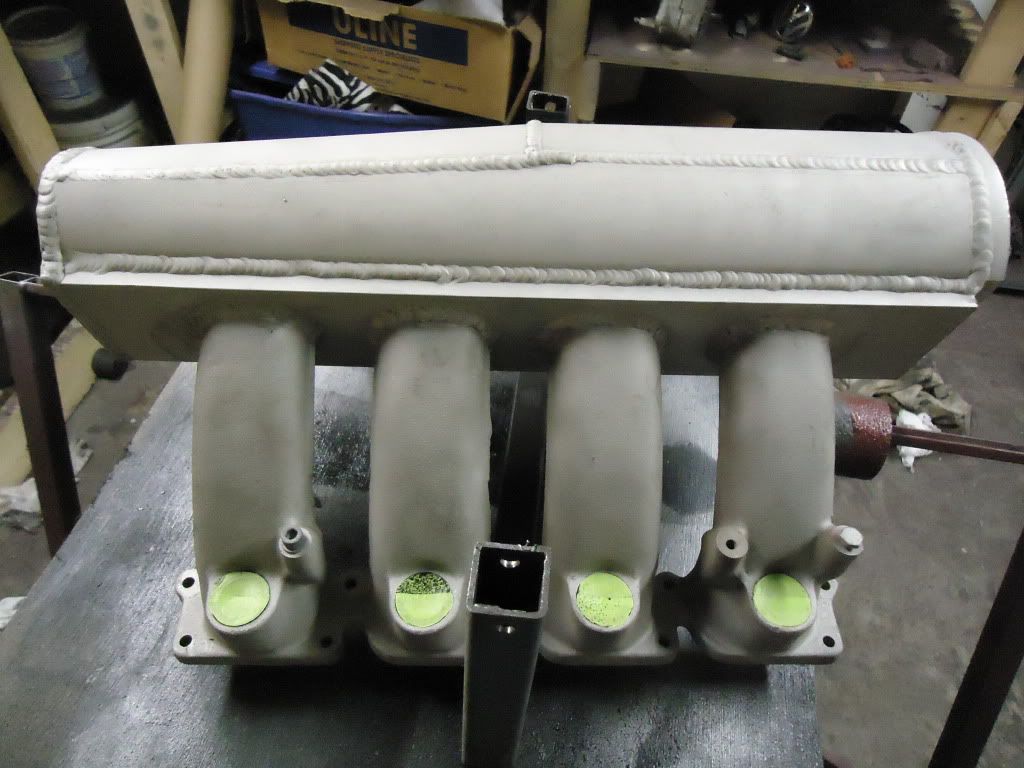

I know you eagle eyes will catch that I didn’t slant the TB flange back… I had it machined a month ago for the TB, and If I slanted it back it wouldn’t fit very well. So I decided to just run with it as is for now. I also listed it for sale, just for fun. If it sells, it sells, if not it works for now. I have a top secret design I am working on for the next one. Look up Laminova, that’s as far as I will go with letting the cat out of the bag. :ninja

Welding inside was a bitch. I need a stubby gas lenses bad. with the stubby back cap I had just enough room in there to get it done. I am jealous of the watercooled Pyrex torch setups that are all of about an 1.5" long total!

Either way, this thing is a beast wont blow apart under pressure and will work well. I also might get it flow benched for the heck of it from the shop putting the head together for me. Or Adam if he feel ambitious :ninja.

Now I can get the fuel rail, and all the plumbing, IC pipes going and inter cooler placement rolling in the car.

water cooled intercooling in an intake manifold??? WWWWWWHHHHHHHAAAAATTTTTTT???

oh wait gm did that like 6 years ago

lol j/k… can’t wait to see the end product

Yeah, the Laminova cores and that idea have been out for a while. The cores are VERYYYY efficient, WAY more than any water air IC out right now, and have little to know pressure loss either. They are damn expensive, like $200 a piece, 4+ cores needed, and require a lot of machine work to mount, flow and run them correctly. Many pro race teams run them in where its legal, and a few production cars use the same idea. Its a cool technology.

just an FYI… if you keep an eye out on either redlineforums.com or cobaltss.net the guys who are going from superchargers to turbo’s tend to get rid of the intake manifold. You could pick up an intercooler for 350 and get 4 cores right there

the LSJ’s use this type of core

Cool, yeah those are the cores right there. I have 4 on the shelf right now, found them wicked cheap online from a company that bought a shit ton and dint use them all so they are liquidating them. I think someone on ebay sells them for like $120 ea or so still.

they require a lot of machining. the ends are o-ringed, sealing the end from the intake stream and sending the water through. then the tube the core sits in has to be tight to the dia of the core fins. and its best to make it a V shape so the air overlaps each core as much as possible without blocking one from the next.

I would totally pump some liquid helium into one of those cores, that would bring the temps down :lol

I wish I knew more about this in my GTP days. Or they really should have intercooled them from the factory. Solid work tho