Awesome build man

finally got the car back from getting the cage done so i can really start to work on this thing now!

and i cut the old shitty subframes off the car. what a PITA that was.

Now that is a proper cage :tup:

…you could add a point and spreader plate to the firewall to prevent wheel intrusion.

Sweet Mike :tup:

:tup: cage looks great.

That cage looks like its for NASCAR lol, nice build!

srs bsns :tup:

it did cross my mind. but i didnt want to add on to the cage build- can always add it on after the fact now that the rest is there. good thought though!!

:tup: i just noticed this thread

We’re adding those on mine as it’s rules required, it’s actually 2 bars per side which combined with a heavily sloped firewall is kind of a pain in the ass.

bro, December 7th lol

took a trip down to Ohio over the weekend to pick up another goodie for the car.

gas was on average about 3.23/gallon outside of NY. WIN!

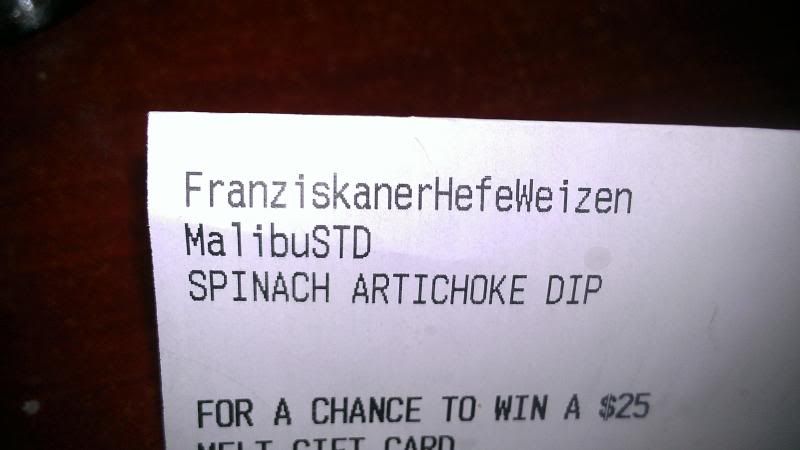

Stopped at The Melt Bar in cleveland. hands down best grilled cheese ive ever had. and an outstanding beer list to choose from.

grilled cheese with deep fried bacon!

and then sunday morning i picked up this! only 27,000 miles on it

which already had all the bushings and tie rods and braces and whatnot installed. minus the aluminum diff mount to adjust pinion angle but thats all thats missing. came with eibach springs and cut stock springs

list of installed parts

BF IRS brace

Urethane Differential Bushings

Delrin Upper Control Arm Bushings

Delrin Lower Control Arm Bushings

Urethane Subframe Bushings

IRS Adjustable Complete Tie-Rod Kit

Adjustable Rear Swaybar Endlinks

Low Profile Subframe Bolts, rear mounts

14MM Subframe Hardware, front mounts

Beers + Install = Win

Let me know

Wow now this is sweet. :tup:

WAITING ON PICS TO BE UPLOADED AND WILL ADD WHEN THEY ARE DONE, BUT HERE IS THE WRITE UP FOR NOW

so been a while since i have done any updates of any kind. been working away on the car though. along with piling up some boxes of empty beer bottles.

scored a Cervini’s Cbra R hood locally for 50 bucks. just had a chipped/cracked corner but that was no big deal to me

once i got it back from having the cage done, i finished scraping and wire wheeling all the sound deadening out of the car. what a pain in the ass. dry ice wouldnt work so a heat gun and an assortment of scrapers did the trick followed buy hours of wire wheeling the rest of the shit

10/22 pulled the rear end out that came with the car- was either a 95 or 96 cobra rear end with 3:27’s in it and 1.5" narrower than a 99-04 rear end. so sold that locally to pay for the 99-04 rear end i bought from Ohio

That IRS was a punk ass mo fo

This thing is going to be super rad when its done. Its been fun to watch the progress and of course drink beers.

10/23 pulled out the Maximum Motorsports K member and Koni shocks out of the Roush to put into this car after the last track day i will probably ever do in the Roush. cut down my times from a 2:19 to a 2:16 the first day and dropped to a 2:13 by the first time out on the 2nd day. so i was happy i cut a good 6 seconds off my previous times there

took a reference picture of my bumpsteer setup so i could get it somewhere close to start out once i installed the suspension in the other car

all pulled out, still assembled to toss it back in- Roush is back on the stock k member but still has tubular A arms and Bilstein shocks so it still looks good lol

car was fully gutted at this point- just the cage and the shell

10/24 installed front suspension in the car

-

-

- Updated - - -

-

10/26 did a rough motor mock up with the motor mounts still on the k member- going to have to cut them off and make something that works a little better

after lots of swearing, beers and sore backs. Justin, @2TurboZ and I got the IRS installed. that fuckin sucks to put in by the way if any of you were wondering.

10/28 New RCR 4 Speed Jerico Trans showed up at my house. REM polsihed gears- pretty much the works

10/29 always a good feeling when you take a grinder to a $600 K member to put new motor mounts on…off with the driver side mount

before cutting

after cutting

10/30 had to cut and modify the front of the oil pan to clearance the steering rack and k member. this was pretty much the first adventure of TIG welding for me. picked up a used Miller Dyanasty 200dx from a guy in Ohio and figured it cant be that hard to teach myself. so i got to work

15 gallon ATL fuel cell arrived. FIA rated and all that nonsense to conform to all the rules

10/31 but in order to put the fuel cell in i needed to cut out the rear trunk out for it to fit and be able to mount i low to keep the weight down lower. but that was a lot of unnecessary weight back there anyway

all cut out

11/1 ordered some over fenders for the rear to widen out the car. at the time i was building the car at this point the max track width for a car in American Iron Extreme was 78" but as of 2015 the rule was upped to 80". did a rough mock up and just taped it on to see what it looked like and where i wanted to go from there

this added about 2" of extra track width in the back, which would take me from 72" up to 76" roughly

11/4 made a template of what i needed to do with the oil pan out of aluminum and finally made it out of some 16ga steel

11/19 ordered another set of headers from speedway motors that i thought would work good without as much modification but they didnt so i ended up just reselling them for a $50 profit