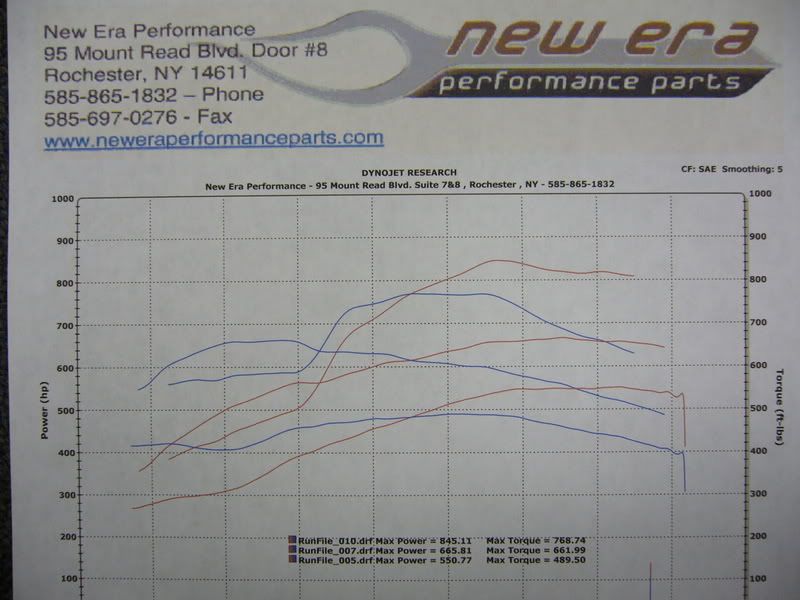

We just finished up a build for our customer, Brandon’s ZO6 that came out very well. Before the car even got to the shop, the performance goals were set, along with the budget. They were both planned for the most practical compromise. Building a weekend cruiser with 800+whp on a fixed budget is going to have compromises.

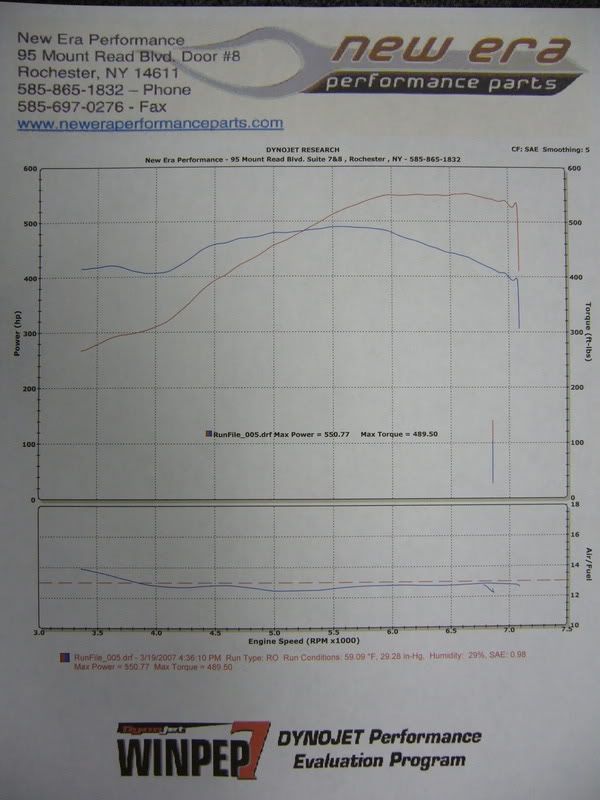

The car was pretty bad ass as it came in–2002 Electron Blue Z06. Old setup was the stock 346 LS6, MS3 cam, 225cc Dart heads, jethot long tube headers, stock midpipes, Corsa touring catback, ASP underdrive pulley, NewEra ported TB, NX wet kit. The car has been to many other big name shops on the East coast. Some good, some not, but thats what we had to work with. Mike at NewEra tuned it last year on our dyno. Found some power and made the tune safer. It ending up at 436whp 385wtq, hit with 150 :tspry: about 600whp and tq. Brandon is a good driver and on stock wheels with tires, ran a 11.2 @ 133 at NYI.

At the end of last year something “broke”. After getting the car and a quick diagnosis of no cranking compression we figured the timming chain probably broke. After tearing it apart it turned out to be running the stock timing set,:bloated: still. The chain was snapped, bent the valves, but the shortblock was fine. And now as a new home.:snky:

The basic performance goals were over 800whp, and with the budget more nitrous fit that well. And a given for this power level was forged internals. Along with more cubes will help for all-around drive ability, with a larger custom grind cam, and more head flow. I really don’t like the dart ls1 heads. The numbers aren’t that good for the money of a aftermarket casting, which is from overseas. The as cast runners are pretty rough, as are the castings over all. However, the budget didn’t alow a better head casting, at this time. So the darts were kept, and got some hand porting. New valves, and better springs.

For the short block, there were no questions about compromising for this power, and leaving room to grow. We’ve had difficulty getting good engine work on motor builds from the local machine shop that “does test work for GM”. A few other locals were also getting poor work, and having problems fixing it. But at the same time, two others purchased stroker motors from LME in TX, and found them to be top notch. One is even doing great after getting hit with a lot spray. And some other driver actions that did nothing good for the motor, but it came out unharmed. We decided to use a LME forged 408 cube shortblock. With a LQ4 iron 6L block, it added some weight to the car, but as a great valve for the cost.

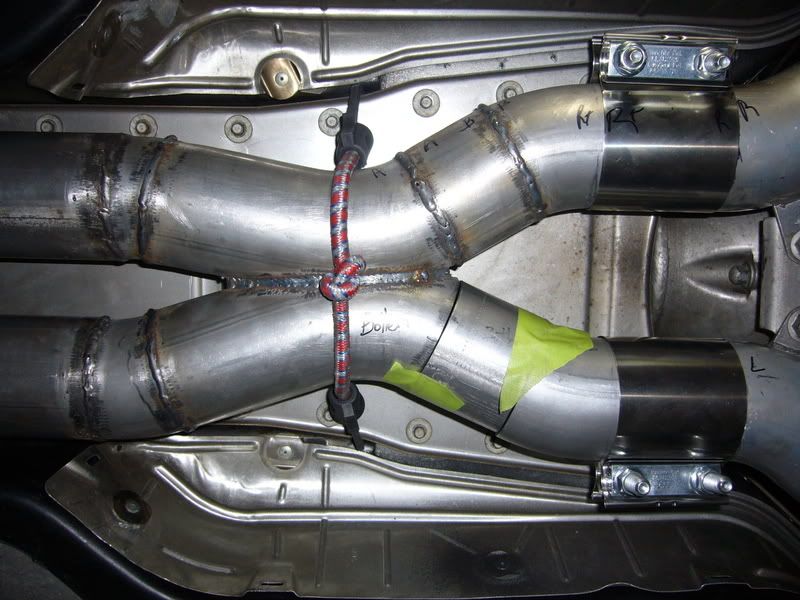

While waiting for that, I got the drivetrain out of the car, and started getting everything ready, adding the 2nd nitrous kit. Got both bottles mounted. I didn’t want to drill any added holes in the car, plus the bottle locations were in the way of the parking brake line and other things. So I used the old holes and made adapter plate, covered it with factory match carpet, for a clean look.

Then made a nice switch panel.

Done and painted, made some labels for it too.

The crate form LME came in. On a stand, the heads went on. ARP head studs, and comedic MLS HGs. Cam, and a JP dual roller timming set (also off the shelf note: to add on site). Custom pushrods, and the new lighter Yella Terra shaft-mount roller rockers. Degreed the cam–it’s a big mother 256/264 .650/.650 114LSA :pimp:everything was fine.

Got the covers on, and sensors to seal the motor up. Had to grind a boss off the block for the motor mounts to fit.

De-burred it for strength, and painted it black.

Motor is ready to go back in. A new Ram hi-flow slave, in the torque tune.And a Ram dual disk clutch, for good stock pedal and engagement. Rated at 900ft/lbs holding force, hopefully it holds up:D Also, an adjustable master.

At its new home, rack back in. Notice the shitty ASP pulley, witch was was later switched for a better unit. ASP was the 1st underdrive pulleys out, but their quality isn’t that great. The center section is alum. and loses its ID on the crank after being removed a few times. Can lead the crank bolts loosening, witch is a PITA on a C5 and C6. A lot of the time the belt grooves have a wobble like there not even centric. Even new we’ve seen them. I switched it for a powerbond unit that we now carry. They’re Aussie built, and the same unit as a SLP just at a lower cost. A very nice piece.

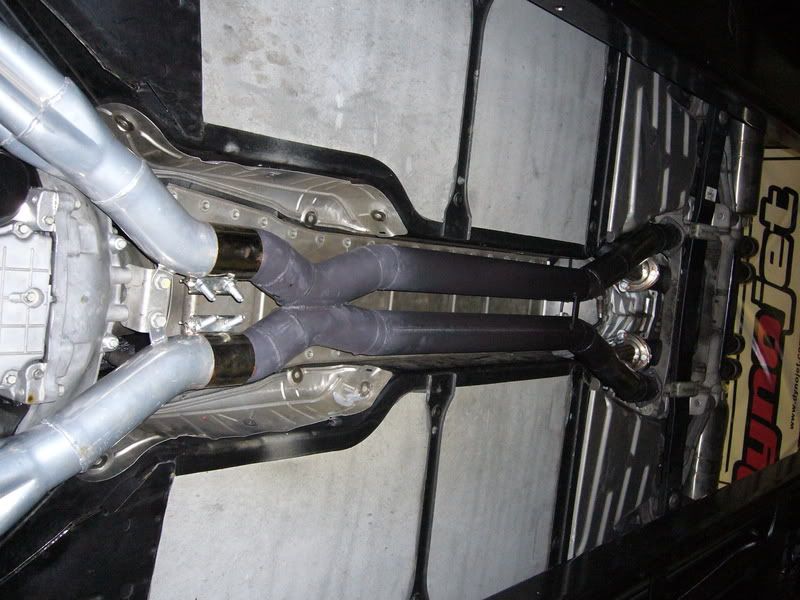

I’m really happy how this came out

I’m really happy how this came out