Hey guys - this may not be new to any of you, but I feel its important to contribute to the site and tonight’s job was to neatly assemble my wiring harness for my Alpine deck in the S14. The one that was in there before for the Panasonic was done with electrical tape. If you think this is fine, please read on.

The Victim - my '95 Nissan 240sx

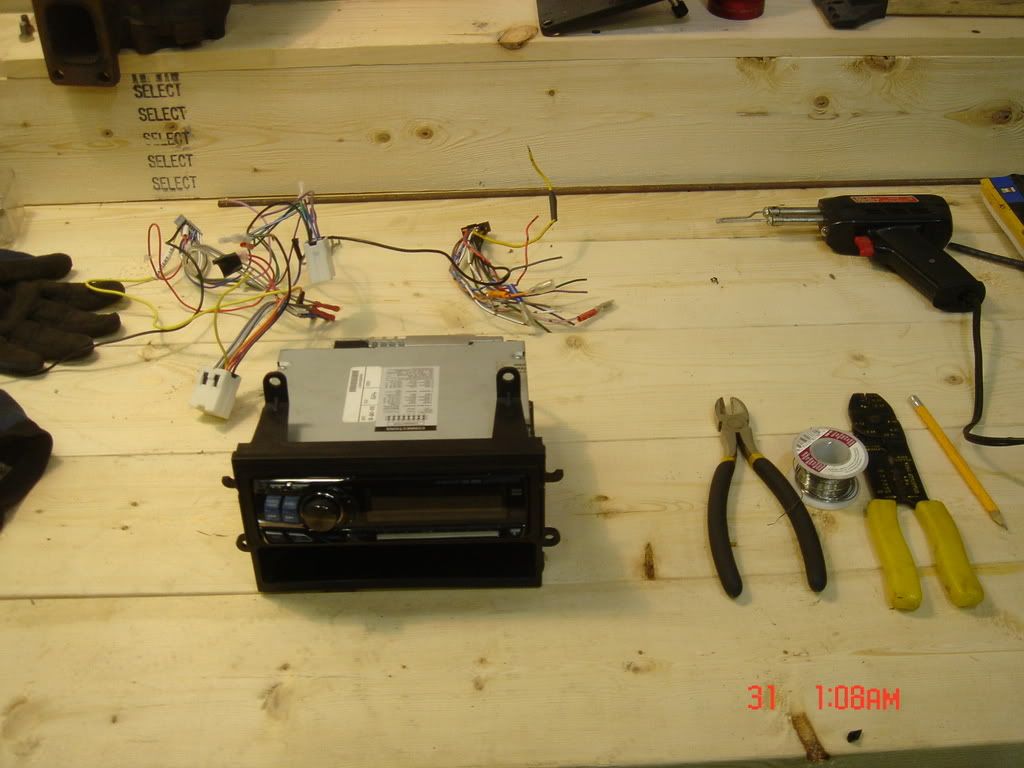

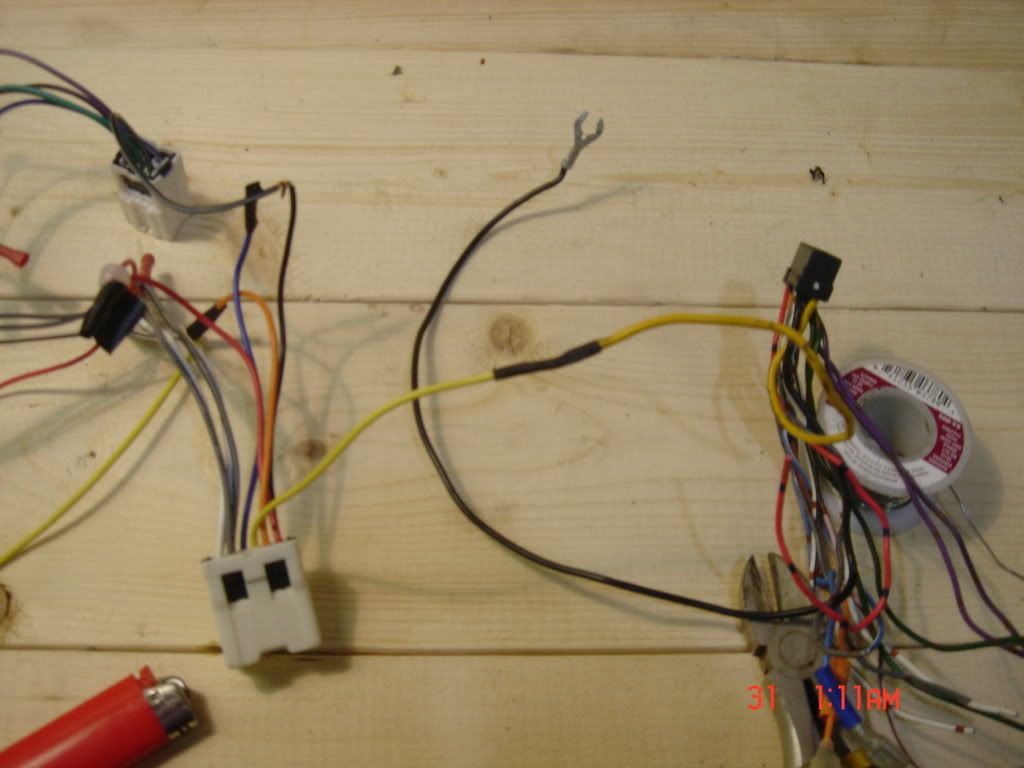

The tools you need - Wire cutters, wire strippers, soldering iron, solder, heat shrink tube, lighter.

And Very important - FLUX - needed for clean and strong connections.

All of these tools are available at your local hardware store - rona, home depot, even the source.

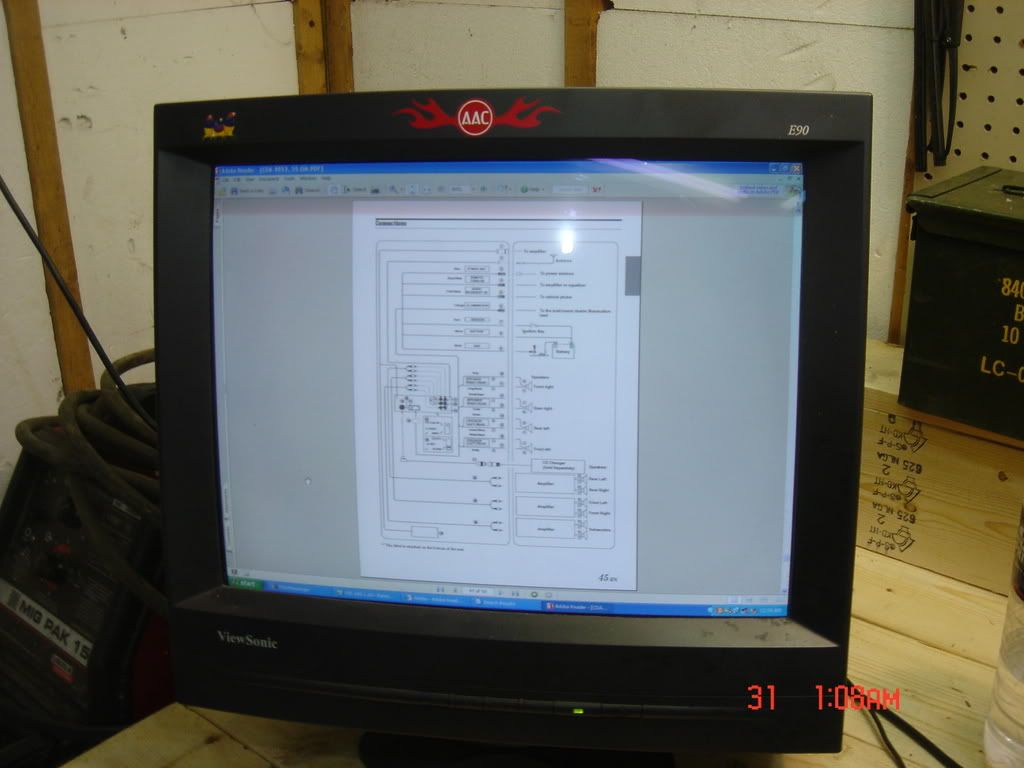

Shop computer - super handy for wiring diagram info.

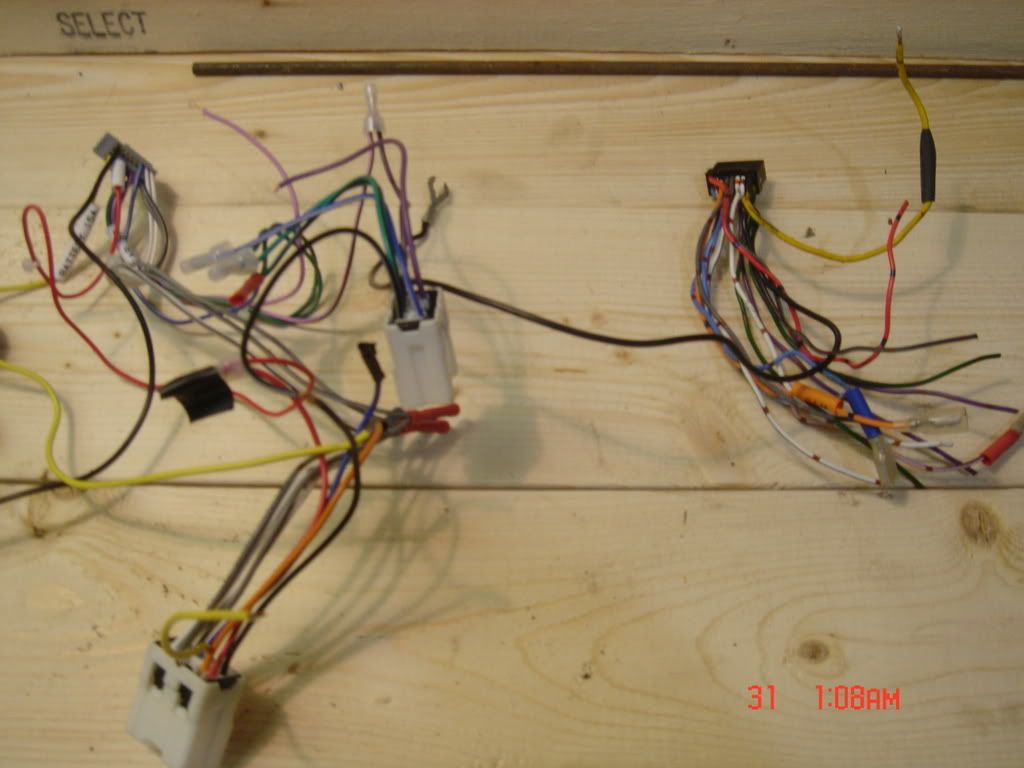

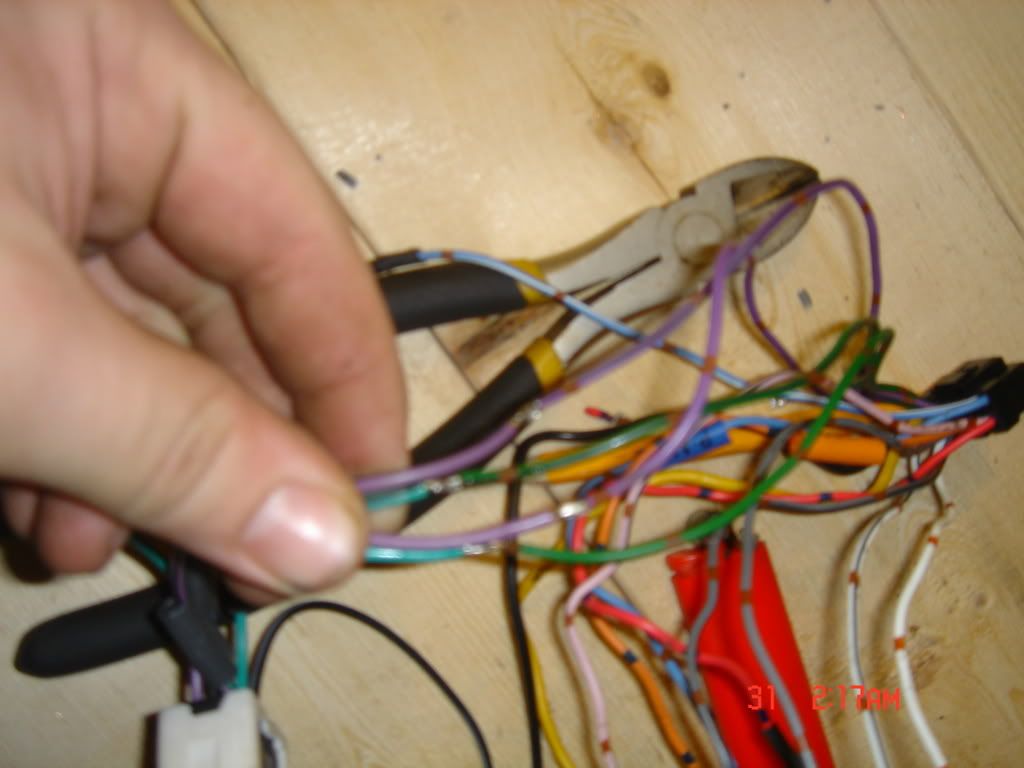

The Rats nest

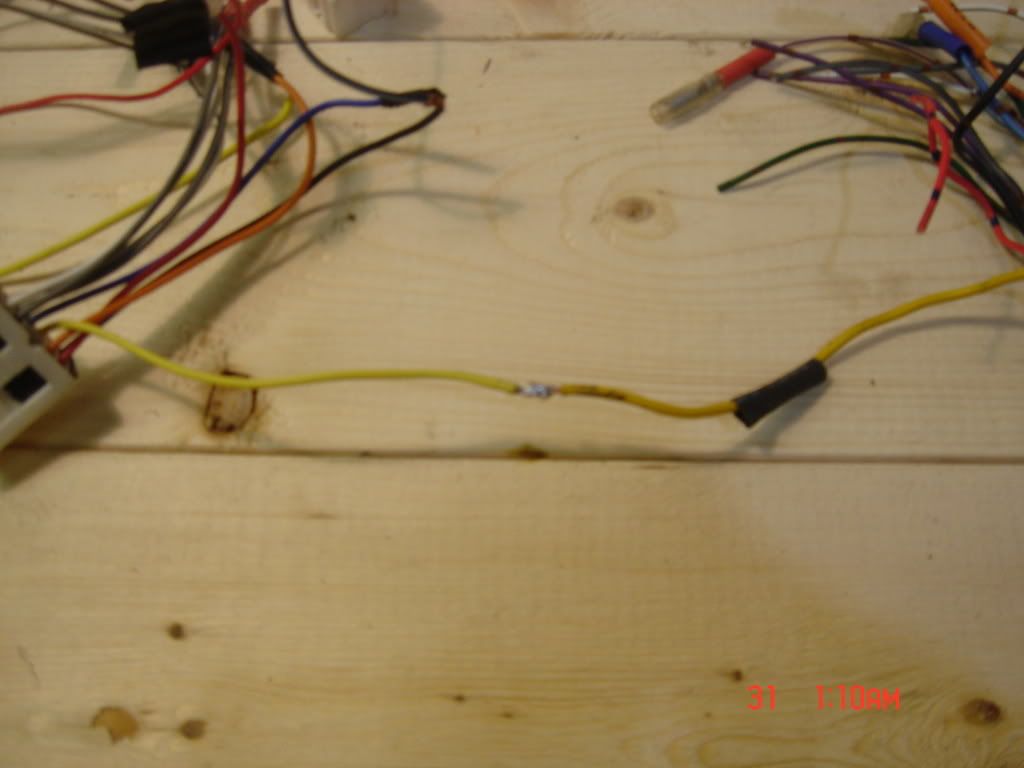

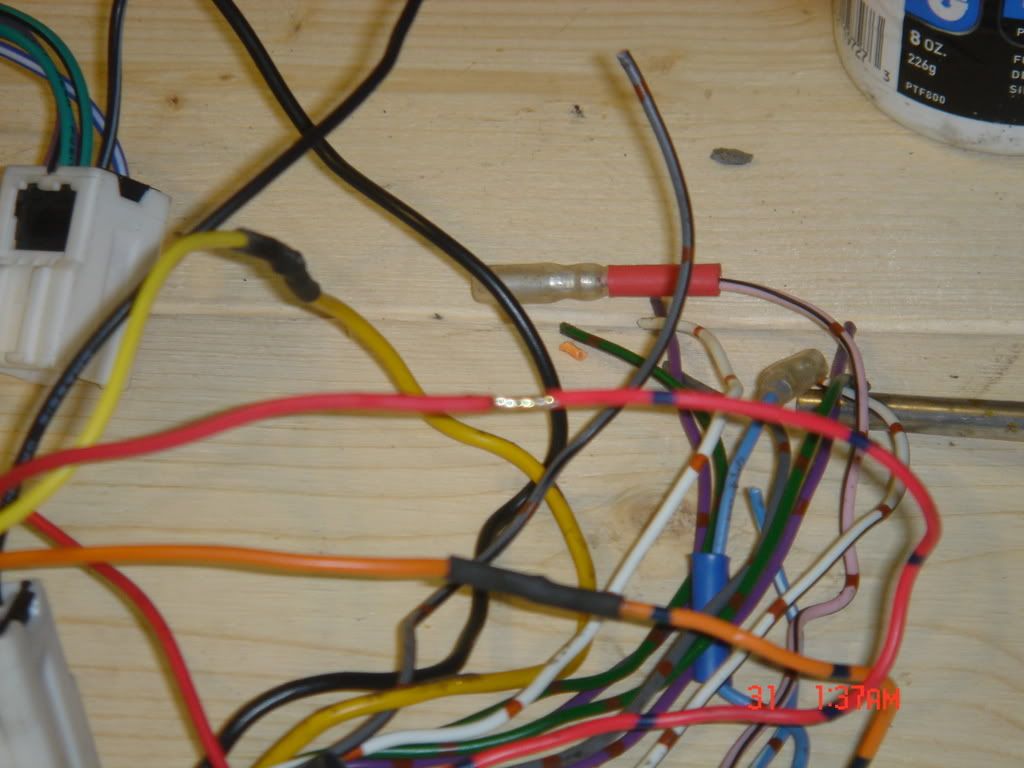

One connection made with heat shrink tube ready to be shrunk

Close up before heating

During heating

Done - Vary Nice!

One by one, take your time. No rush! I spent 2 hours on this at half speed.

Thank you flux! Excellent, strong connection

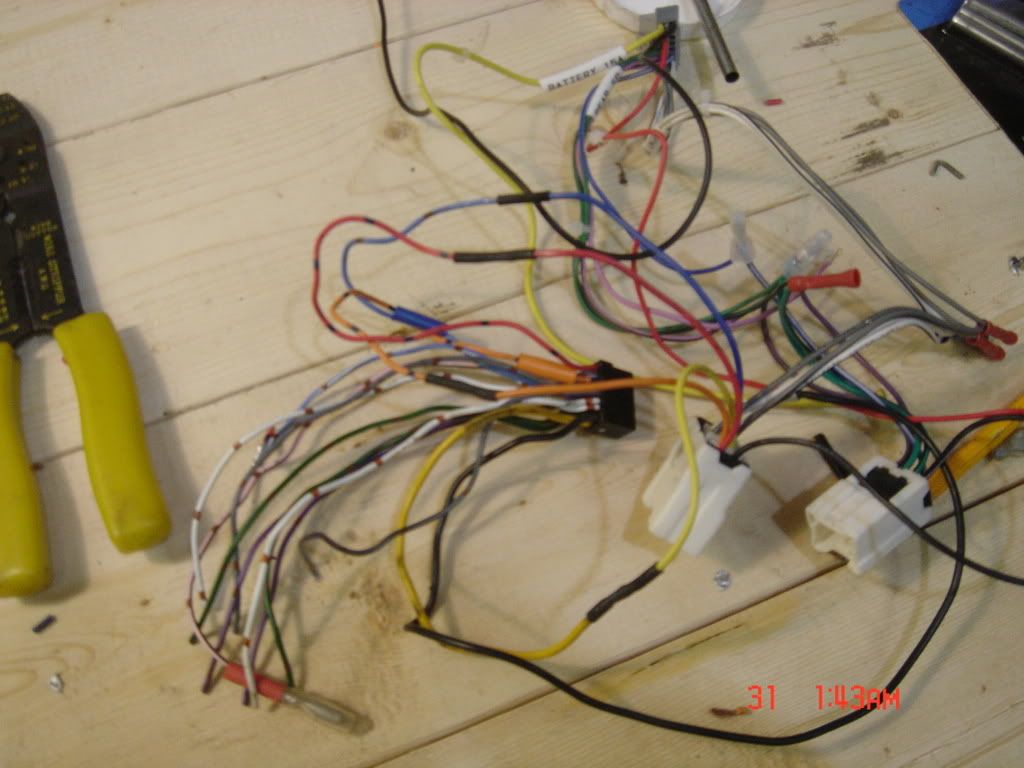

More progress is made.

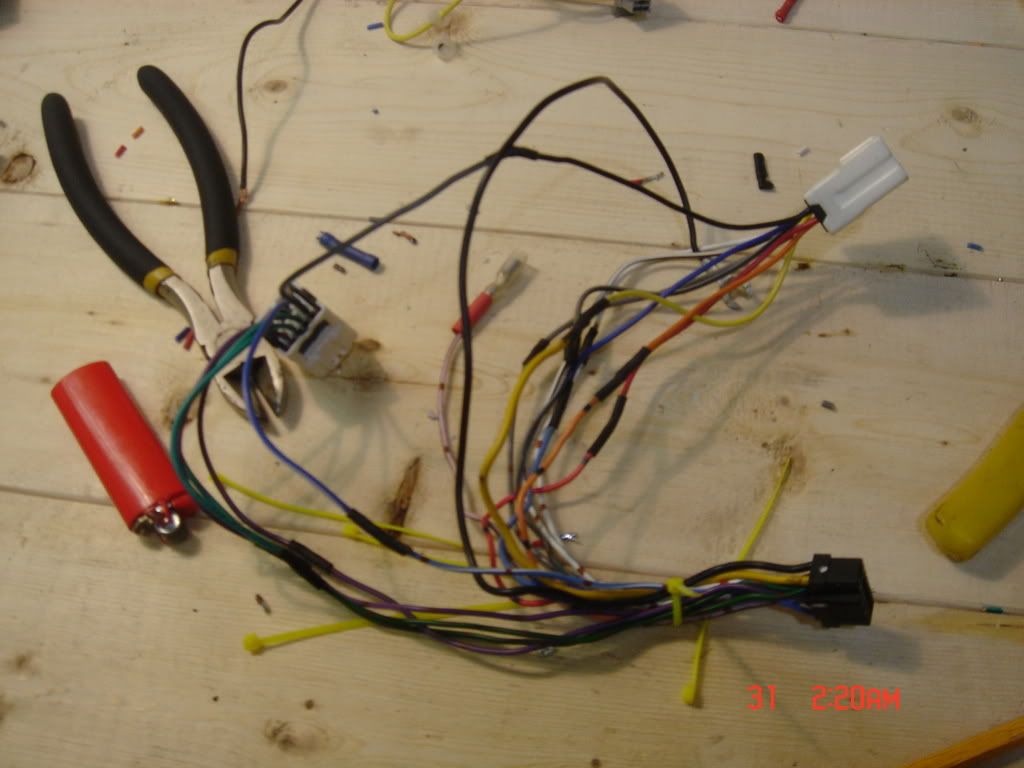

Old harness cut off - I was using it as a guide for some of the wiring code.

Almost done soldering and heat shrinking

4 solid connections - no need to strip a tonne of wire, half a cm to a cm is fine, but make sure the solder is in contact with all of the wires (this is what flux really helps with)

The tedious part is done. Start cleaning up the harness.

This one is for Brendan aka simplemind7.

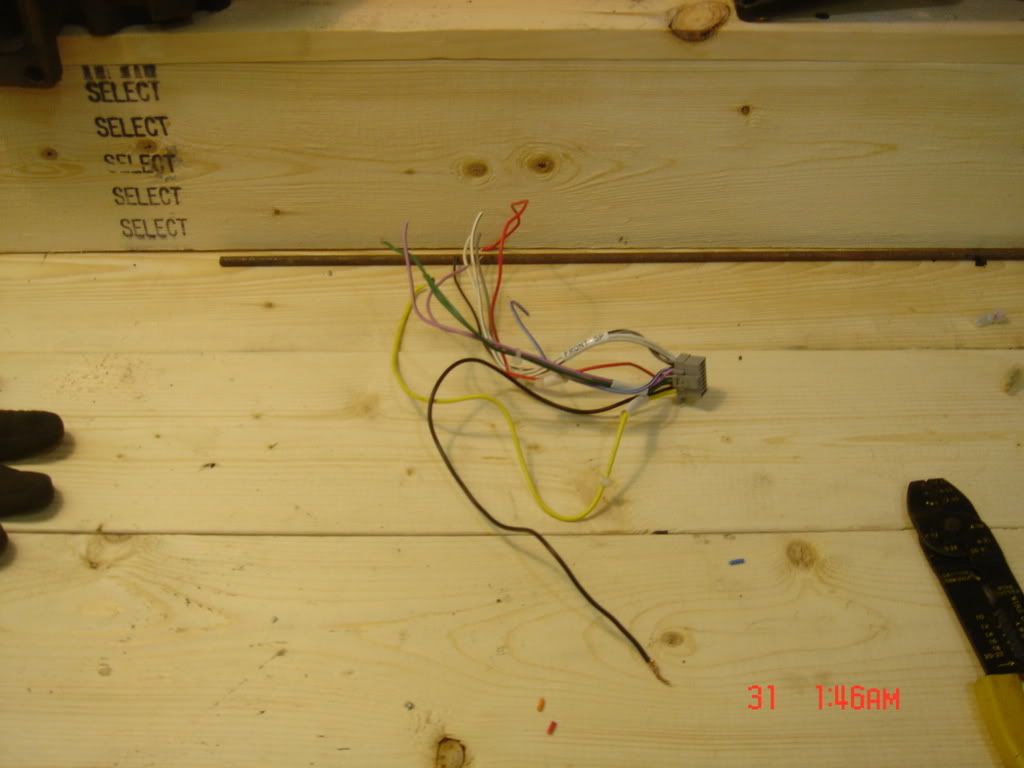

Fresh and clean

In the back of the deck. So easy to work with.

Another angle

Much more manageble

And we have power! Great success!

Mocked up.

I plan on finishing the install off in the morning - to tired for now. I feel as though taking the proper time to do a job, however small it may be, is always worth it in the end.

Cheers,

Dave