I think i need to come over for a rummage sale with a pocket full of cash and a few pounders of PBR

well, after nearly a week of nonstop wrenching, the car is up and running, motor sounds normal.

I do have to hand it to Murphy, though…as I let the car idle in the driveway, coolant began spewing out from the nipple on the overflow tank - it just snapped on its own. So, off to the store tomorrow to buy a new tank, and then drop the car off for tuning.

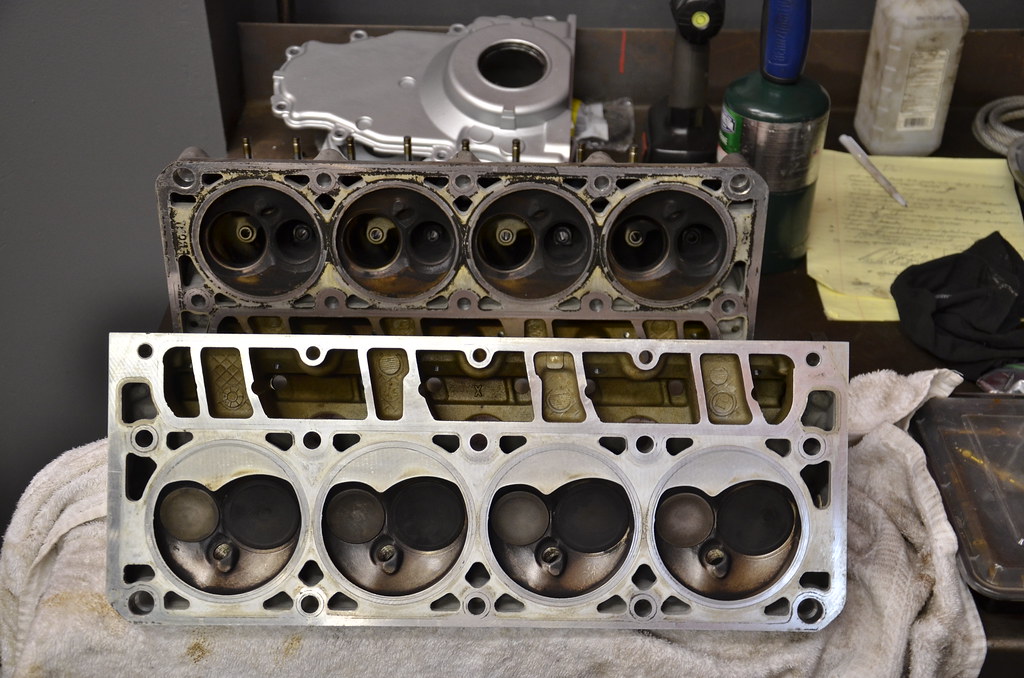

Cylinder Head Cleaning and Reassembly

Since one of my 317 heads was trashed from the bent/broken valve in the initial mishap, I decided to go down a different route with heads and grab a used set of 241s locally - they were very clean, low mileage, and the price was right. Although they don’t technically flow as well as 317s, I was willing to give them a try since I did not have to mill them to bring up compression.

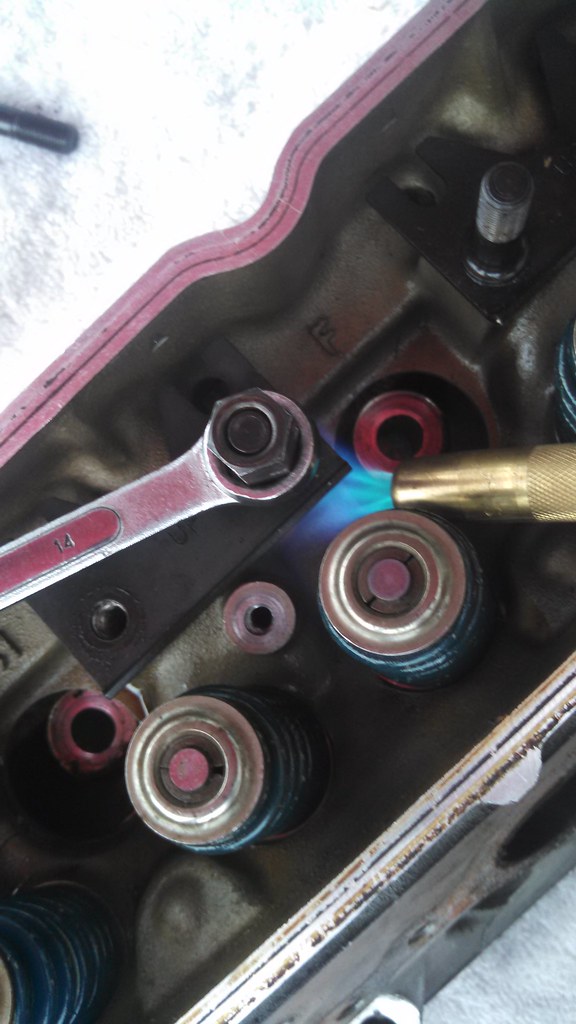

The heads came assembled with stock springs and valves, but the previous owner had installed a set of stud-style rocker mounts (with loctite), so I spent an evening with a handheld MAP torch coaxing them out.

IMG_20150530_200448_163 by Norbert Ogiba, on Flickr

IMG_20150530_200448_163 by Norbert Ogiba, on Flickr

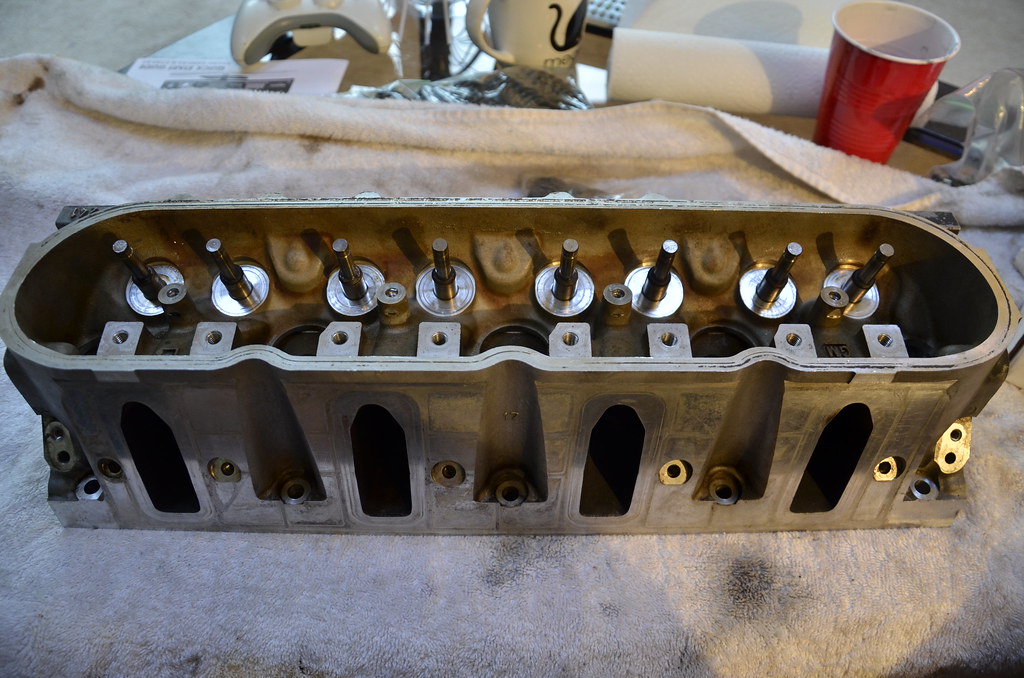

Before pictures - heads were removed from a 2002 Pontiac Trans Am with 50,000 miles.

_DSC3835 by Norbert Ogiba, on Flickr

_DSC3835 by Norbert Ogiba, on Flickr

_DSC3836 by Norbert Ogiba, on Flickr

_DSC3836 by Norbert Ogiba, on Flickr

I cleaned all surfaces with a rag and isopropyl alcohol to remove grease and dirt, and then ran a plastic scraping tool over all surfaces to remove the last of the old gasket material. They came out looking very nice.

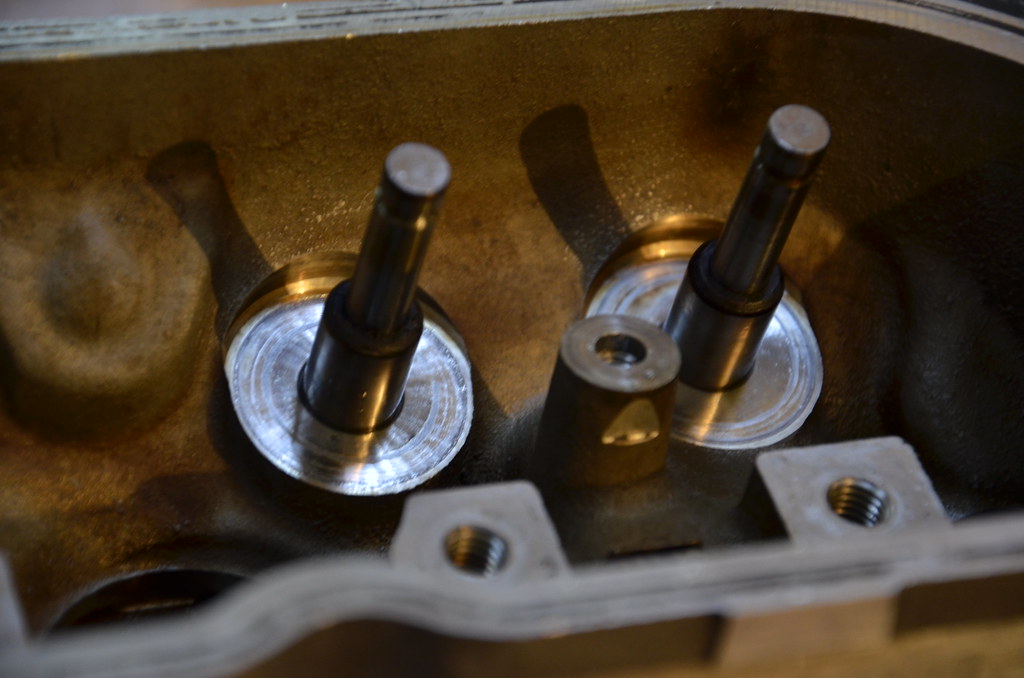

Bare valve seat base

_DSC3838 by Norbert Ogiba, on Flickr

_DSC3838 by Norbert Ogiba, on Flickr

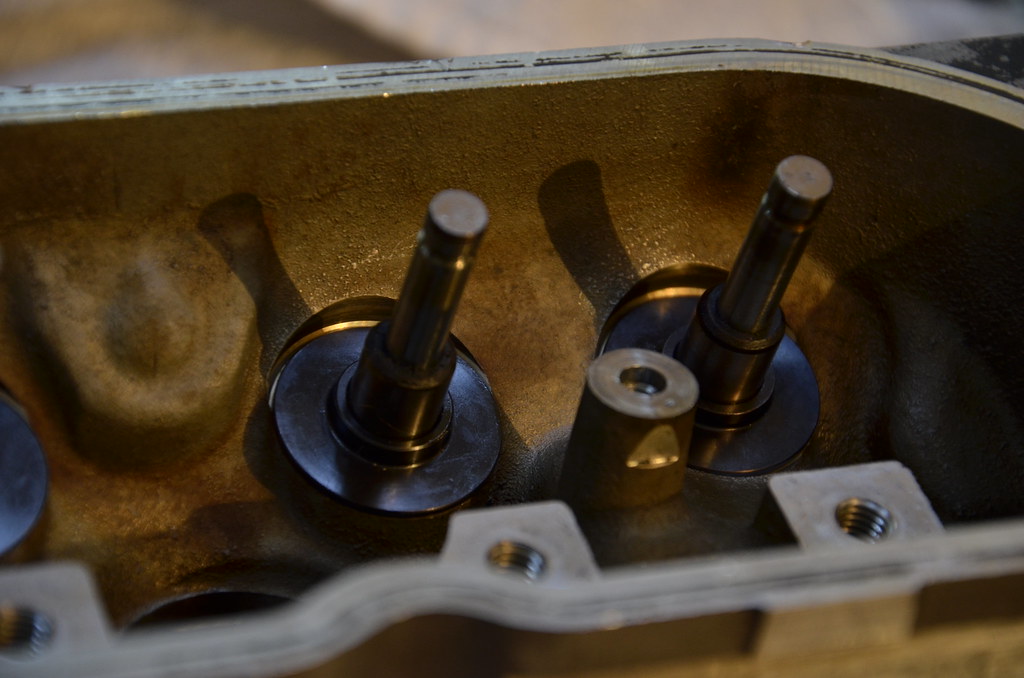

Seats installed

_DSC3839 by Norbert Ogiba, on Flickr

_DSC3839 by Norbert Ogiba, on Flickr

Brand new PRC dual valve springs with Titanium valve retainers.

_DSC3841 by Norbert Ogiba, on Flickr

_DSC3841 by Norbert Ogiba, on Flickr

Installed using my homemade spring compressor.

_DSC3842 by Norbert Ogiba, on Flickr

_DSC3842 by Norbert Ogiba, on Flickr

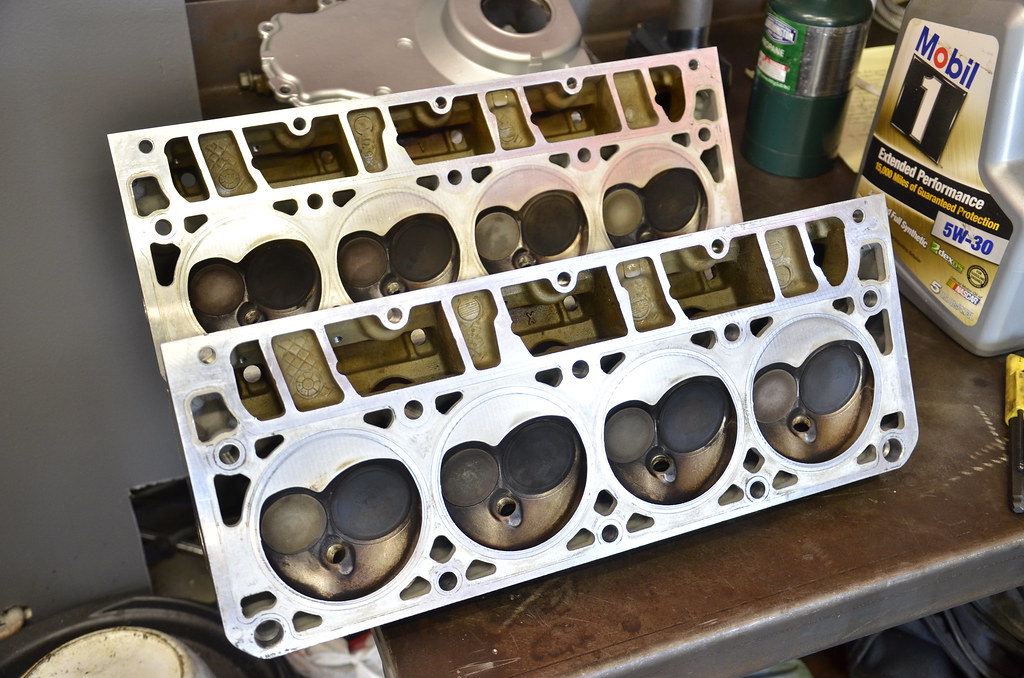

Before and after cleaning service on the heads, all done by hand. I actually really enjoyed this part.

_DSC3844 by Norbert Ogiba, on Flickr

_DSC3844 by Norbert Ogiba, on Flickr

The heads came out really nicely in the end. Of course I installed all new GM OEM valve seats and seals in addition to the dual springs and Ti retainers. The factory valve locks were in good shape and were reused.

_DSC3850 by Norbert Ogiba, on Flickr

_DSC3850 by Norbert Ogiba, on Flickr

-

-

- Updated - - -

-

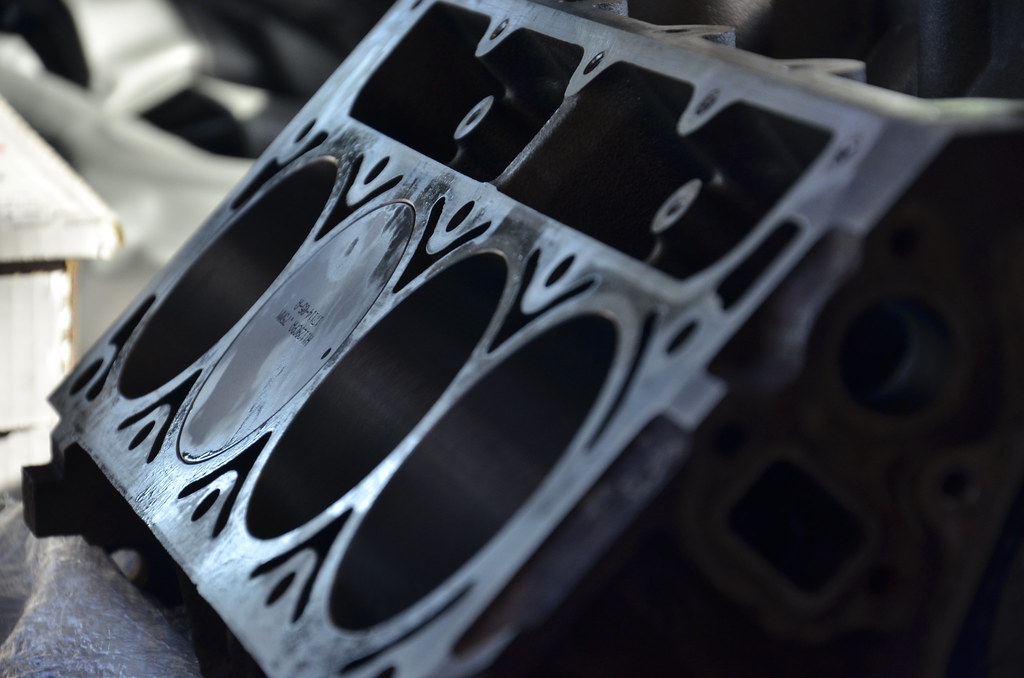

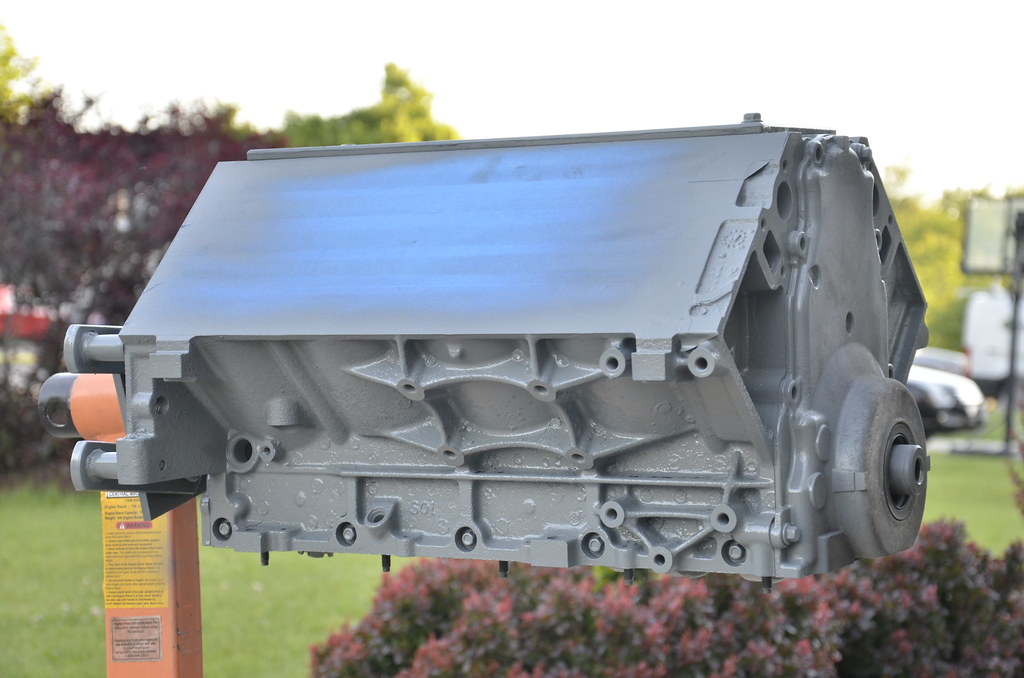

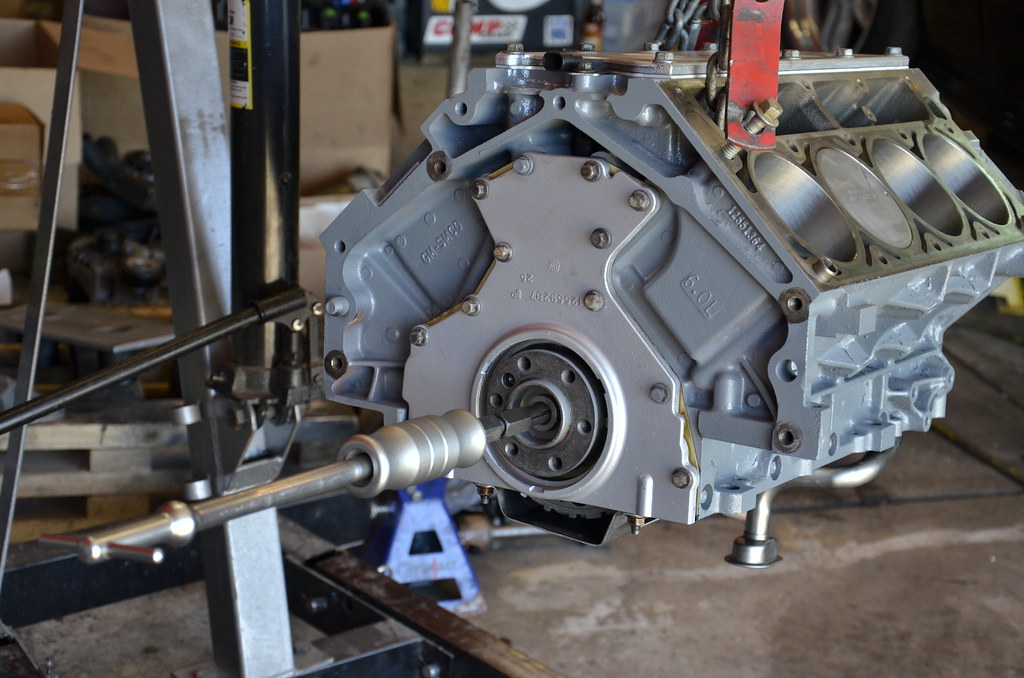

Engine block cleanup and paint

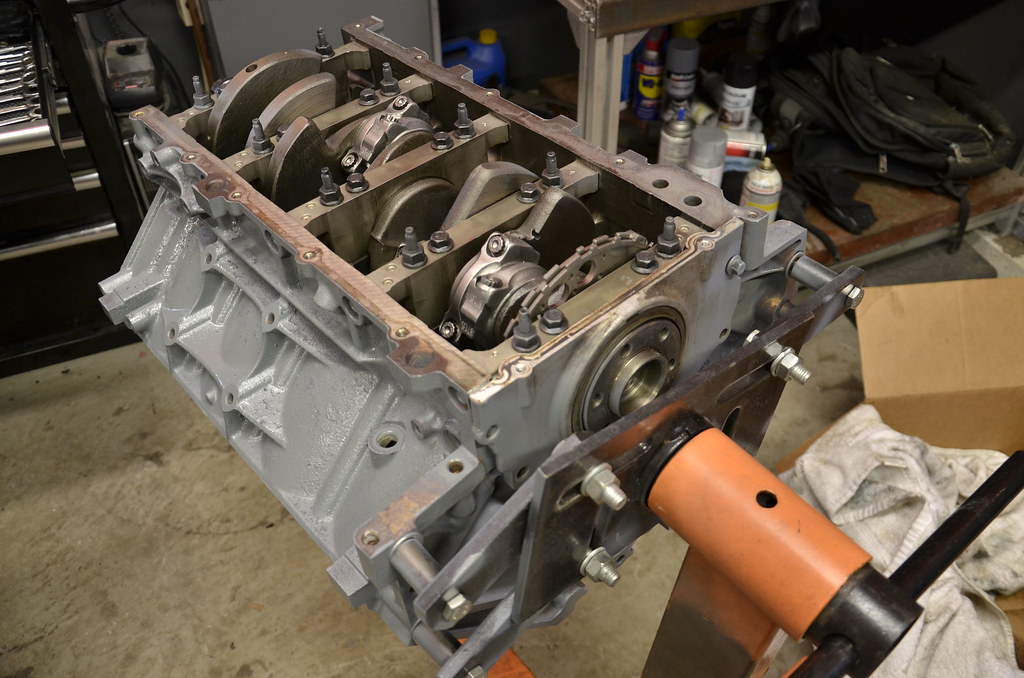

Bottom end came back from the machine shop on Tuesday June 2nd, so I jumped right in.

_DSC3854 by Norbert Ogiba, on Flickr

_DSC3854 by Norbert Ogiba, on Flickr

_DSC3855 by Norbert Ogiba, on Flickr

_DSC3855 by Norbert Ogiba, on Flickr

Unwrapping the goodies

_DSC3856 by Norbert Ogiba, on Flickr

_DSC3856 by Norbert Ogiba, on Flickr

Flat-top piston goodness. My builder oiled the motor lightly to prevent flash corrosion on deck surfaces

_DSC3857 by Norbert Ogiba, on Flickr

_DSC3857 by Norbert Ogiba, on Flickr

Up on the stand, degreased, taped, and ready for paint

_DSC3858 by Norbert Ogiba, on Flickr

_DSC3858 by Norbert Ogiba, on Flickr

I had a set of nasty looking front and rear covers laying around, so rather than tape off those areas, I just snugged them up with 2 bolts to keep the paint out of the internals.

_DSC3859 by Norbert Ogiba, on Flickr

_DSC3859 by Norbert Ogiba, on Flickr

_DSC3860 by Norbert Ogiba, on Flickr

_DSC3860 by Norbert Ogiba, on Flickr

I chose a high high engine primer to start with, followed by medium gray high heat engine enamel. The idea was a nice “clean” color that would make leaks easy to spot, and not draw too much attention. I was going to go with an aluminum alloy silver, but since this is an iron block, it wouldn’t have looked “right” on the porous iron texture.

_DSC3861 by Norbert Ogiba, on Flickr

_DSC3861 by Norbert Ogiba, on Flickr

.

Certainly won’t win any concourse awards but I like how it came out.

_DSC3862 by Norbert Ogiba, on Flickr

_DSC3862 by Norbert Ogiba, on Flickr

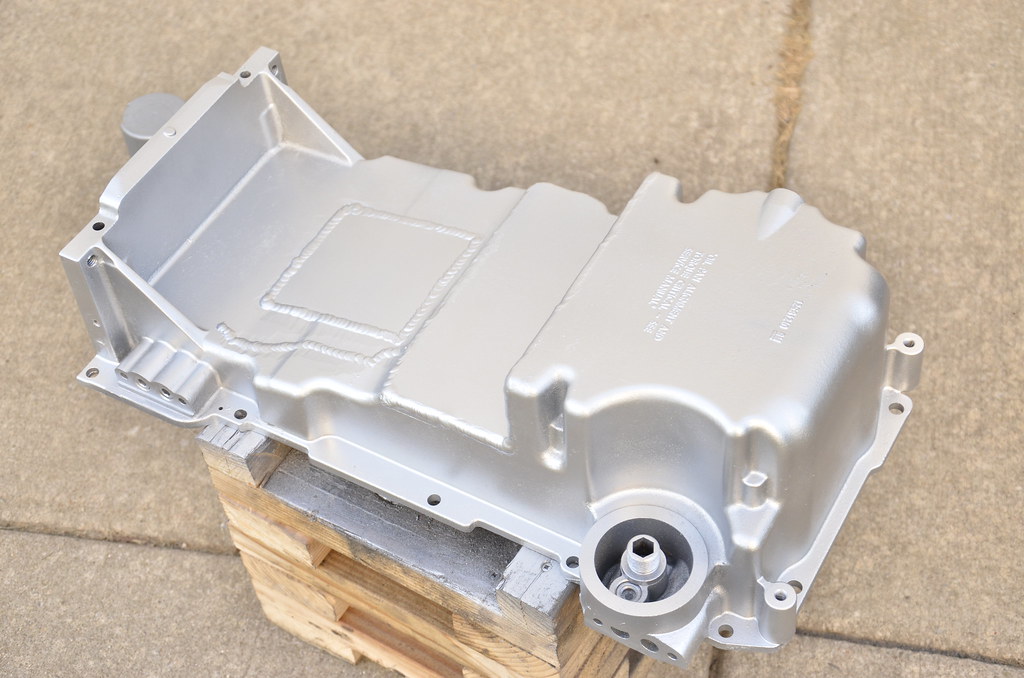

Oil pan was welded up by a local shop and got a fresh coat of silver aluminum color paint.

_DSC3863 by Norbert Ogiba, on Flickr

_DSC3863 by Norbert Ogiba, on Flickr

:tup:

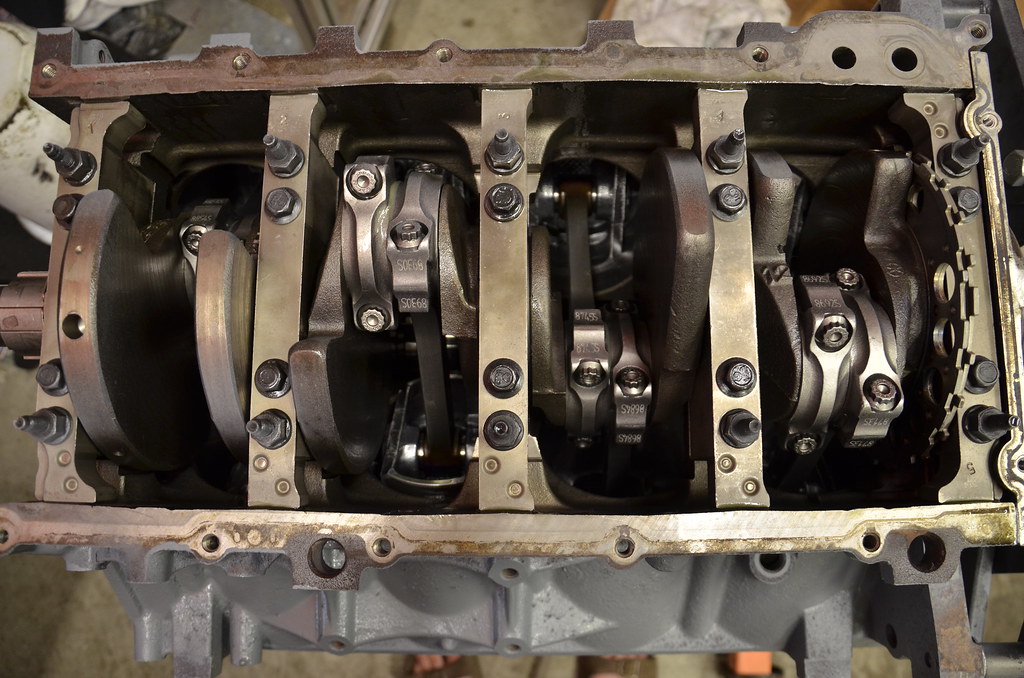

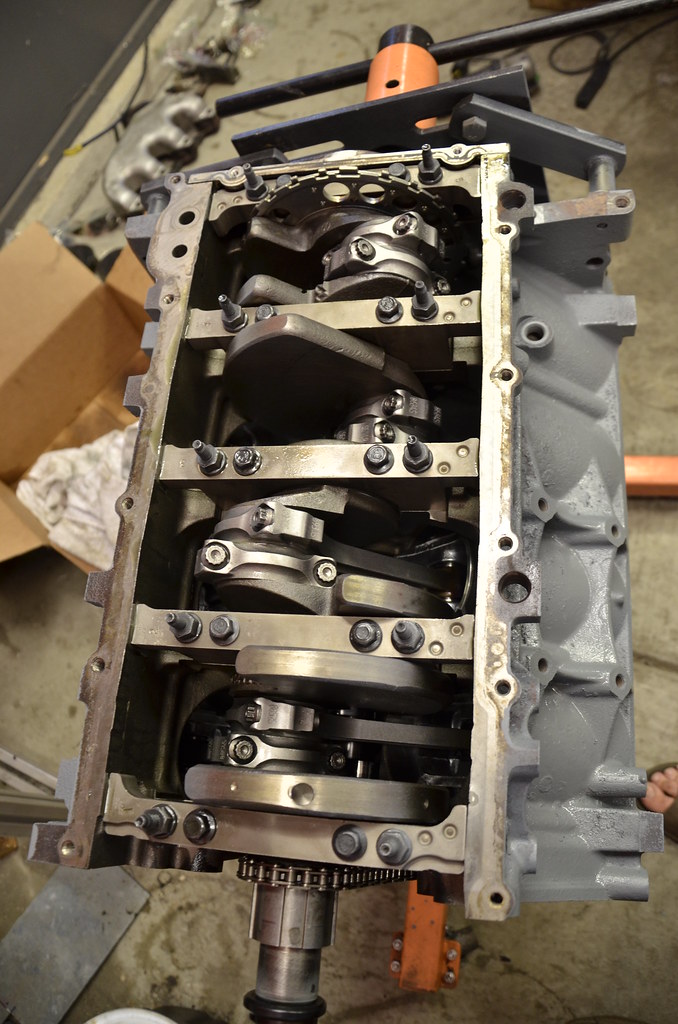

Bottom End Assembly

Scat I Beam Forged Rods, ARP hardware

_DSC3868 by Norbert Ogiba, on Flickr

_DSC3868 by Norbert Ogiba, on Flickr

_DSC3870 by Norbert Ogiba, on Flickr

_DSC3870 by Norbert Ogiba, on Flickr

The stock crank was in good shape, so it was reused - rod journals were within clearance and were just polished, but the mains needed to be ground .010 with appropriate size Clevite “P” bearings installed.

_DSC3872 by Norbert Ogiba, on Flickr

_DSC3872 by Norbert Ogiba, on Flickr

_DSC3873 by Norbert Ogiba, on Flickr

_DSC3873 by Norbert Ogiba, on Flickr

_DSC3874 by Norbert Ogiba, on Flickr

_DSC3874 by Norbert Ogiba, on Flickr

Ready for the oil pan.

_DSC3875 by Norbert Ogiba, on Flickr

_DSC3875 by Norbert Ogiba, on Flickr

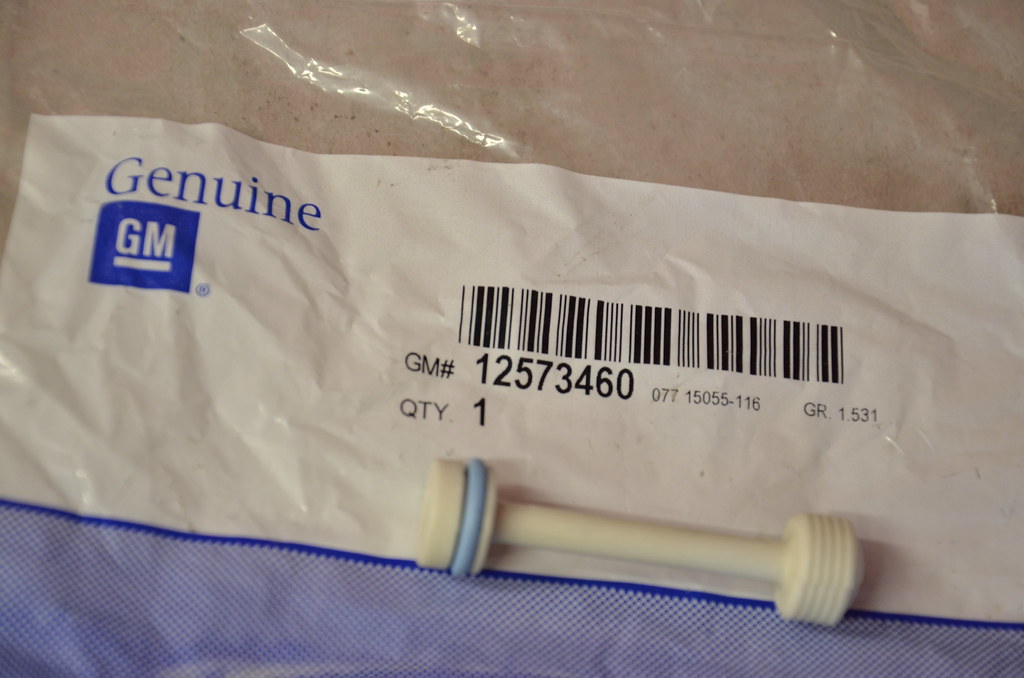

A new oil galley barbell plug was installed as the old one’s o-ring had grown brittle and dry.

_DSC3876 by Norbert Ogiba, on Flickr

_DSC3876 by Norbert Ogiba, on Flickr

A new OEM GM LS2 timing chain replaced the weaker factory Gen 3 chain.

_DSC3877 by Norbert Ogiba, on Flickr

_DSC3877 by Norbert Ogiba, on Flickr

I have to find the pictures, but I also disassembled the stock oil pump and scrubbed every component. Nothing special to report besides the typical oil staining and deposits. The pressure relief spring was not stuck, but I still cleaned the spring bore to make sure it moved perfectly.

Oil pump was installed over new timing set followed by front and rear covers, which each received a new main seal. Oil control tray, was installed followed by the pickup tube (don’t pinch that o-ring!). Lastly the balancer was pressed on using my homemade tool (M16x2 threaded rod, washers, nuts, thrust bearing)

_DSC3881 by Norbert Ogiba, on Flickr

_DSC3881 by Norbert Ogiba, on Flickr

Pilot bearing was replaced with a new OEM unit

_DSC3880 by Norbert Ogiba, on Flickr

_DSC3880 by Norbert Ogiba, on Flickr

Dab of RTV at the corners of the front and rear covers seals them against the oil pain

_DSC3882 by Norbert Ogiba, on Flickr

_DSC3882 by Norbert Ogiba, on Flickr

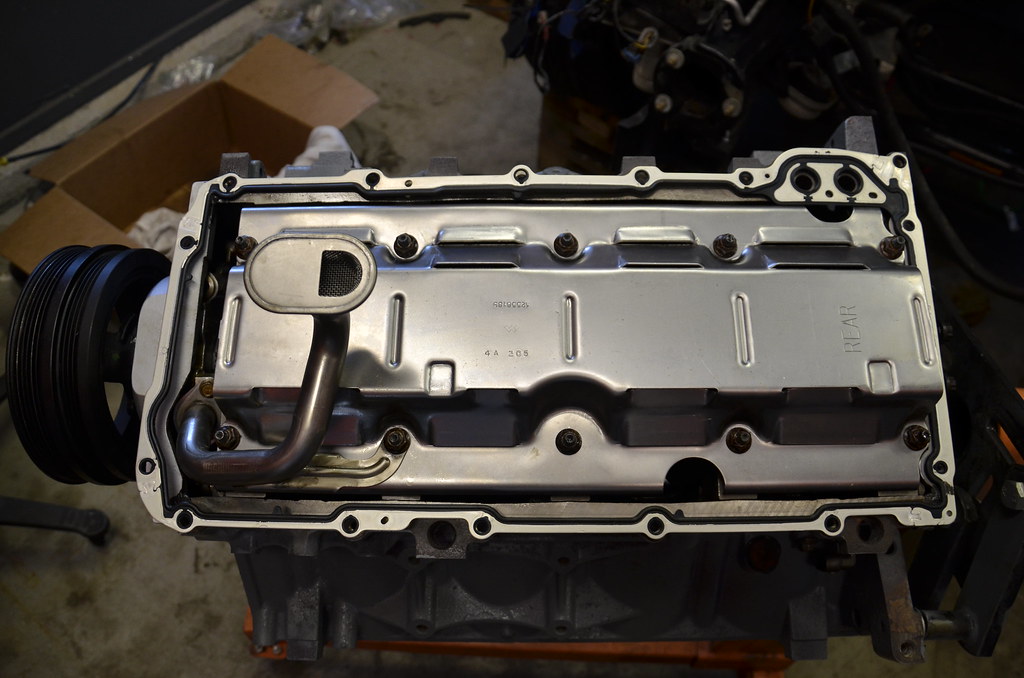

I removed the windage tray, internal pan oil tubes, and pickup tube, and cleaned them with warm soapy water to make sure no foreign material was hiding in there. Cleaned them up and blew out with compressed air to make them like new.

_DSC3883 by Norbert Ogiba, on Flickr

_DSC3883 by Norbert Ogiba, on Flickr

Oil pan on, aligned, and torqued.

_DSC3884 by Norbert Ogiba, on Flickr

_DSC3884 by Norbert Ogiba, on Flickr

Is this a slow build up (for dramatic effect) to vroom vroom?

car is done i just ripped past your house a lil while ago. I have some tuning related loose ends to tie up (dead MAF sensor) but for the most part it’s nearly done.

-

-

- Updated - - -

-

and no dramatic build up i’m just documenting all my work since i slammed through it in a week’s time

Builds motor doesn’t check spark plug wire :funny2:

That sucks, but it sounds like you are recovering from this.

X …

I might have thrown it out when I moved but I had a stock MAF kicking around.

^ i might snag it from you…Nick Mahoney has one as well, if you don’t need it I may just buy it off you

drove the car to work today, runs awesome besides cold start driveability, but I am working with New Era on that.

Posts motor on stand upsidedown.

Then posts car is done.

Fuuuu.

Come finish mine.

You can have it for free if we can find it.

Top End Assembly

I flipped her over on the stand and went to town.

Brand new OEM LS7 lifters got an oil bath for 2 weeks prior to assembly.

_DSC3885 by Norbert Ogiba, on Flickr

_DSC3885 by Norbert Ogiba, on Flickr

Pre-assemble into lifter trays, which were scrubbed clean and blown out with compressed air prior to use

_DSC3887 by Norbert Ogiba, on Flickr

_DSC3887 by Norbert Ogiba, on Flickr

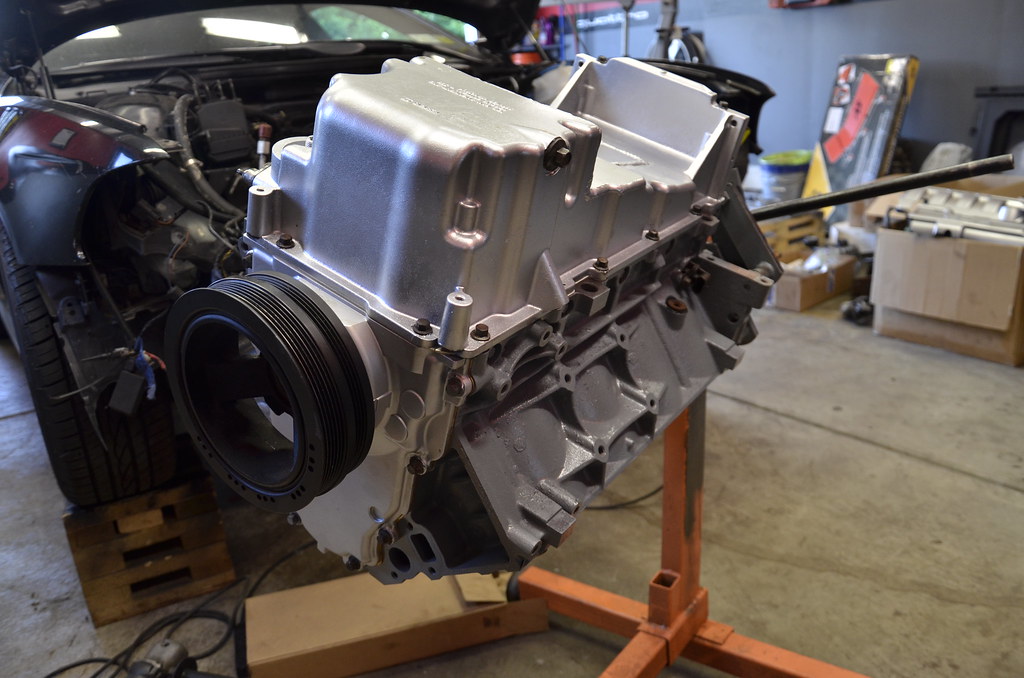

Cylinder head dowels installed, headgaskets laid in place. I chose an OEM MLS LS3 6.2 headgasket to match the .030" overbore.

_DSC3889 by Norbert Ogiba, on Flickr

_DSC3889 by Norbert Ogiba, on Flickr

_DSC3890 by Norbert Ogiba, on Flickr

_DSC3890 by Norbert Ogiba, on Flickr

_DSC3891 by Norbert Ogiba, on Flickr

_DSC3891 by Norbert Ogiba, on Flickr

_DSC3892 by Norbert Ogiba, on Flickr

_DSC3892 by Norbert Ogiba, on Flickr

Ready for a fresh head (love this shot)

_DSC3893 by Norbert Ogiba, on Flickr

_DSC3893 by Norbert Ogiba, on Flickr

Get her down into place, making sure not to snag the surface with the corner of a dowel.

_DSC3894 by Norbert Ogiba, on Flickr

_DSC3894 by Norbert Ogiba, on Flickr

ARP head bolts (varying length design) were torqued in sequence and in 3 stages to the appropriate spec using the required thread lube on the threads, washers, and under the head of the bolts.

_DSC3895 by Norbert Ogiba, on Flickr

_DSC3895 by Norbert Ogiba, on Flickr

Once both heads were on, they got new plugs:

_DSC3896 by Norbert Ogiba, on Flickr

_DSC3896 by Norbert Ogiba, on Flickr

Since I was in a time crunch to get the car done, the rest went together fairly quickly, so I will let the pictures tell the story.

:tup:

Engine/Trans Assembly and Installation into car

Bolted on a bunch of crap like the front accessories, starter, manifolds, coolant sensors, etc. Cleaned the pressure plate and flywheel with isopropyl alcohol to remove any fingerprints or grease, installed both with ARP hardware, torqued to spec. Joining these two bastards was super fun on my own!

_DSC3923 by Norbert Ogiba, on Flickr

_DSC3923 by Norbert Ogiba, on Flickr

_DSC3924 by Norbert Ogiba, on Flickr

_DSC3924 by Norbert Ogiba, on Flickr

_DSC3925 by Norbert Ogiba, on Flickr

_DSC3925 by Norbert Ogiba, on Flickr

_DSC3926 by Norbert Ogiba, on Flickr

_DSC3926 by Norbert Ogiba, on Flickr

and, in ya go

_DSC3927 by Norbert Ogiba, on Flickr

_DSC3927 by Norbert Ogiba, on Flickr

Workspace = filthy

_DSC3928 by Norbert Ogiba, on Flickr

_DSC3928 by Norbert Ogiba, on Flickr

Finally got it in (without removing the driveshaft no less)

_DSC3928 by Norbert Ogiba, on Flickr

_DSC3928 by Norbert Ogiba, on Flickr

Technician117 doing what he does best

_DSC3929 by Norbert Ogiba, on Flickr

_DSC3929 by Norbert Ogiba, on Flickr

_DSC3930 by Norbert Ogiba, on Flickr

_DSC3930 by Norbert Ogiba, on Flickr

_DSC3931 by Norbert Ogiba, on Flickr

_DSC3931 by Norbert Ogiba, on Flickr

Reconnecting vacuum lines and wiring

_DSC3932 by Norbert Ogiba, on Flickr

_DSC3932 by Norbert Ogiba, on Flickr

Final reassembly

_DSC3933 by Norbert Ogiba, on Flickr

_DSC3933 by Norbert Ogiba, on Flickr

Interior back together

_DSC3937 by Norbert Ogiba, on Flickr

_DSC3937 by Norbert Ogiba, on Flickr

Done!

_DSC3934 by Norbert Ogiba, on Flickr

_DSC3934 by Norbert Ogiba, on Flickr

Fired it up and let it idle while checking oil pressure, coolant temps, and general leaks. Some minor things but no deal breakers. The biggest “oh crap” moments were a minor miss due to a loose plug wire, and a leak from the OPSU (replaced with an appropriate plug). As I walked out to hop in and take it for the maiden voyage, it started puking coolant out of the overflow bottle, where a nipple had cracked and broken on a nearly new tank

_DSC3935 by Norbert Ogiba, on Flickr

_DSC3935 by Norbert Ogiba, on Flickr

_DSC3936 by Norbert Ogiba, on Flickr

_DSC3936 by Norbert Ogiba, on Flickr

Naturally only one store had one in stock locally and they had closed for the day, so it pushed back my schedule by another day. However, I tossed a new one in, and took the car to be tuned.

Mileage at the time of engine rebuild for future reference.

_DSC3939 by Norbert Ogiba, on Flickr

_DSC3939 by Norbert Ogiba, on Flickr

Met my goal and made it out to Columbus, OH for Timmayfest - got it strapped down on the dyno (very high heat and humidity).

_DSC3970 by Norbert Ogiba, on Flickr

_DSC3970 by Norbert Ogiba, on Flickr

Fairly disappointed at the numbers - 360whp and 349 lbft. The only change was a more restrictive exhaust in the form of cats, a resonator, and slightly smaller diameter piping. Last year I made 427whp/400lbft on a local dyno. Go figure.

_DSC3971 by Norbert Ogiba, on Flickr

_DSC3971 by Norbert Ogiba, on Flickr

Had to make a stop on the way home:

_DSC4064 by Norbert Ogiba, on Flickr

_DSC4064 by Norbert Ogiba, on Flickr

Cam iron block 6.2 only making 360hp? What is going on with your combo? What heads and cam are you running? Why run cats?

not a 6.2…it’s a 364/6.0 with a .030 overbore. 228/228, .588/.588 @ 112. stock 241 heads, stock CTS-V exhaust manifolds dumping into 2.5" BMW exhaust with stock cats. I want cats because I hate the catless smell and drive the car to work most days.

some little things here and there

had the car tuned at New Era Performance, with a focus on driveability- pretty happy with the result.

Picking up the car - some nice machinery out front (check out the sick drug dealer SUV)

IMG_0169 by Norbert Ogiba, on Flickr

IMG_0169 by Norbert Ogiba, on Flickr

IMG_0170 by Norbert Ogiba, on Flickr

IMG_0170 by Norbert Ogiba, on Flickr

IMG_0171 by Norbert Ogiba, on Flickr

IMG_0171 by Norbert Ogiba, on Flickr

Finally had an alignment done - ironically this is the first one I have done in the 4 years and 43K miles I’ve owned the car for. Rear camber was about a degree too negative, and front toe needed work too.

IMG_0184 by Norbert Ogiba, on Flickr

IMG_0184 by Norbert Ogiba, on Flickr

IMG_0182 by Norbert Ogiba, on Flickr

IMG_0182 by Norbert Ogiba, on Flickr

As usual, passed inspection without a hitch - just plug and play

IMG_0185 by Norbert Ogiba, on Flickr

IMG_0185 by Norbert Ogiba, on Flickr

Next up: installing this

IMG_0192 by Norbert Ogiba, on Flickr

IMG_0192 by Norbert Ogiba, on Flickr

IMG_0200 by Norbert Ogiba, on Flickr

IMG_0200 by Norbert Ogiba, on Flickr

so i can stop doing this

-

-

- Updated - - -

-

who wants to buy this thing? at this point I feel I have gone as far as is practical, I am itching to start working on something else