Hit up the shop today - got the main diagonal in. Before someone mentions it, I plan on taking the tacks off and cleaning up the weld joints next weekend before continuing the rest of the cage - I just didn’t have any emery cloth today.

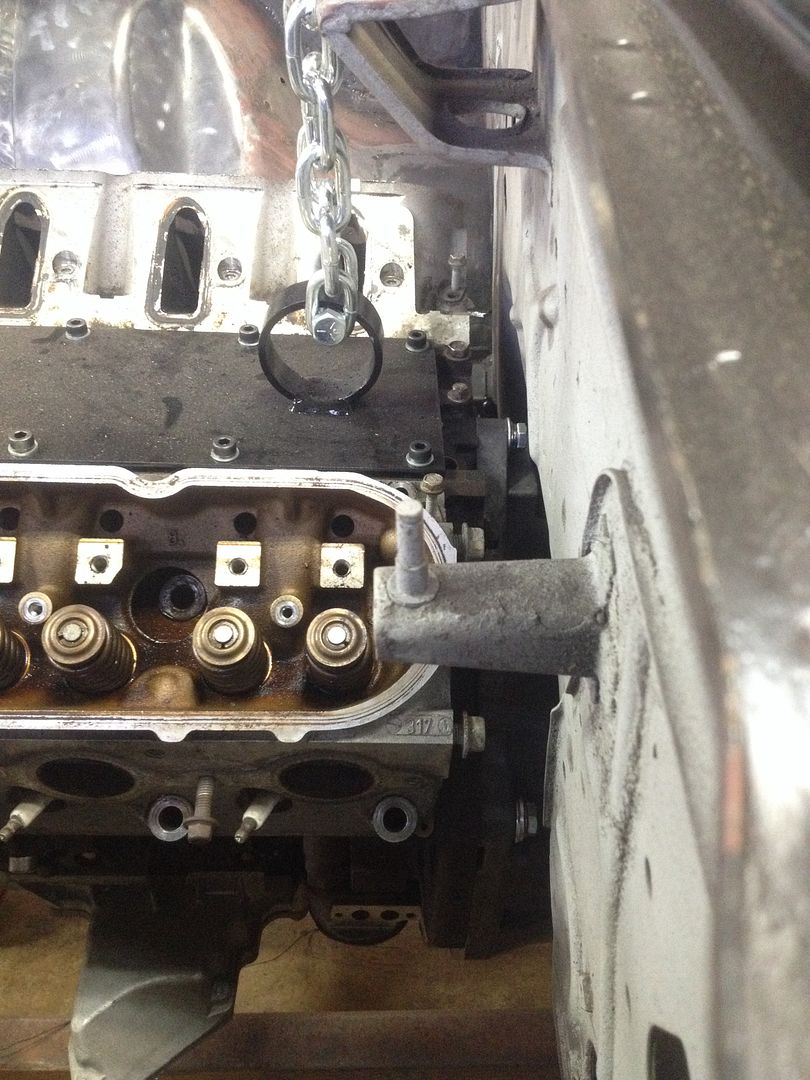

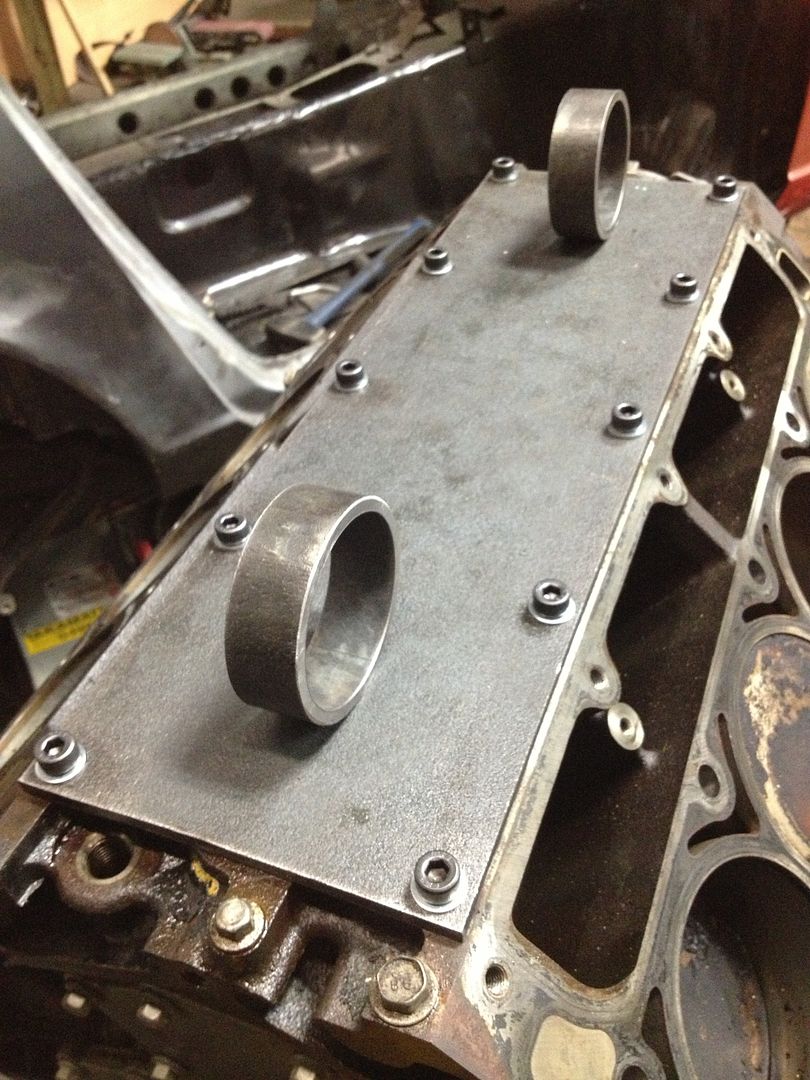

Also finished up that lift plate. Buying some engine goodies this week hopefully come in for the weekend.

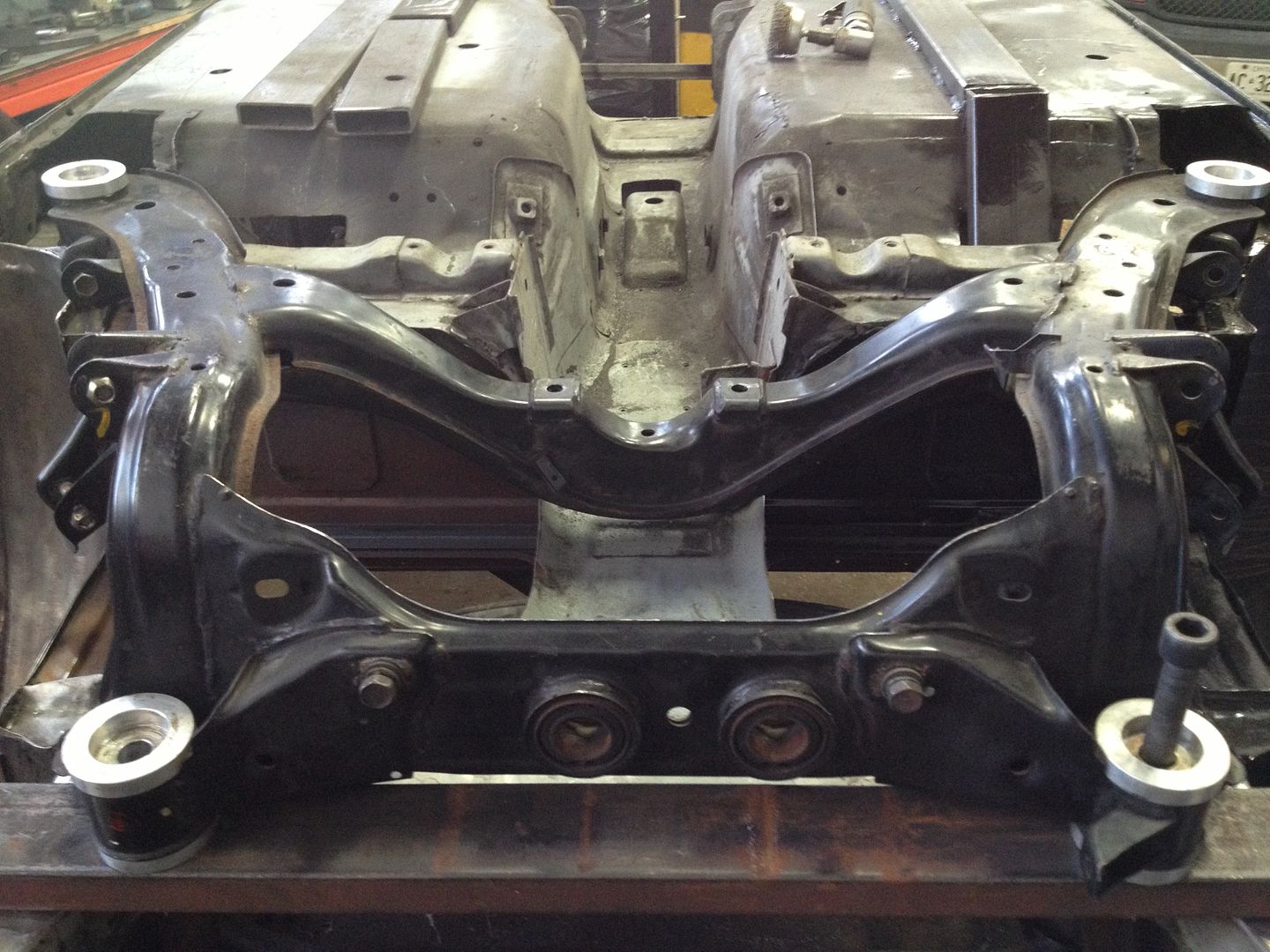

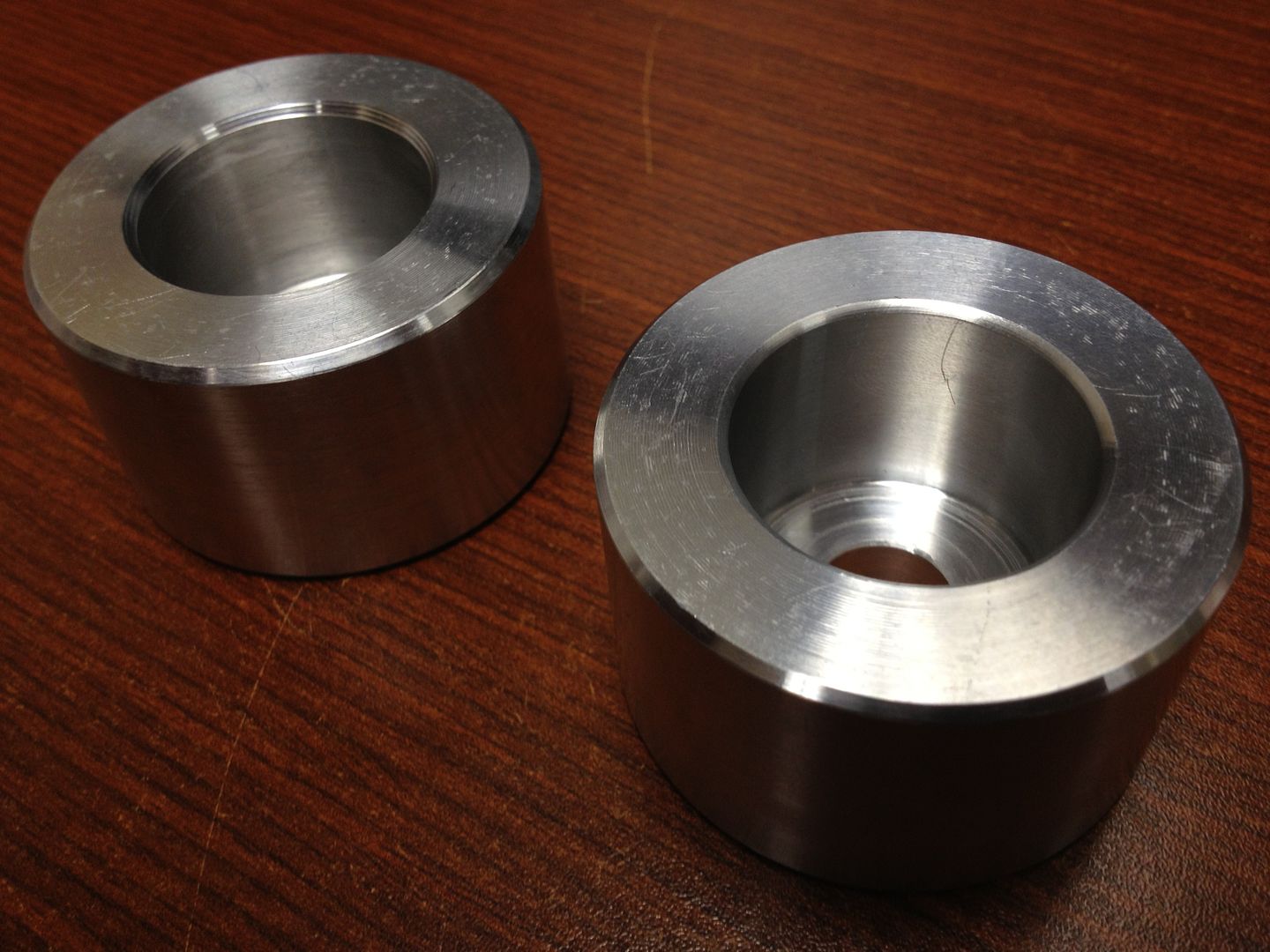

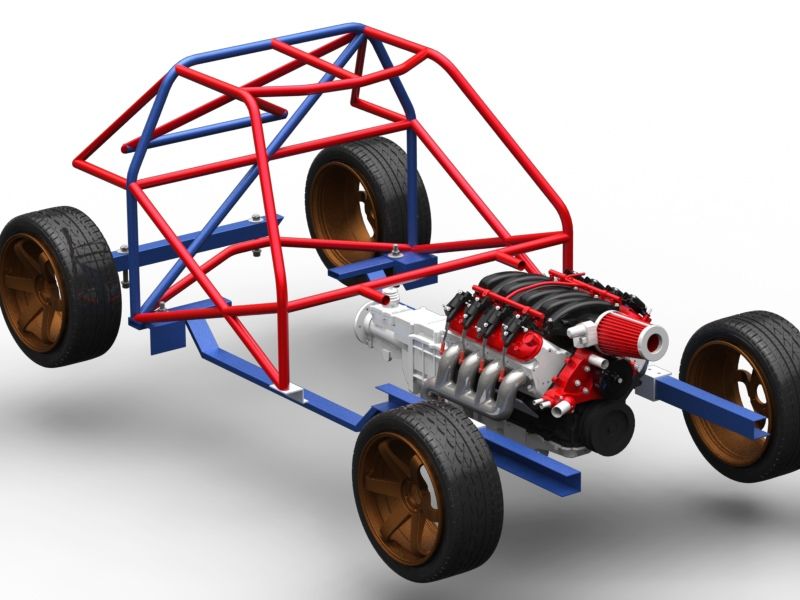

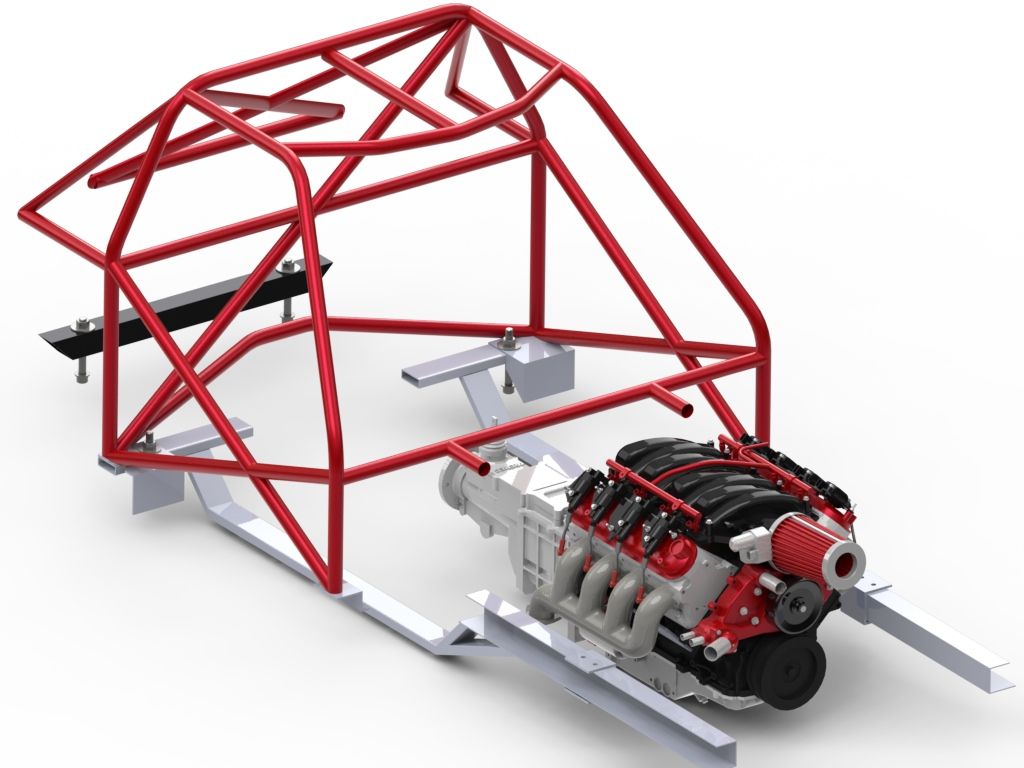

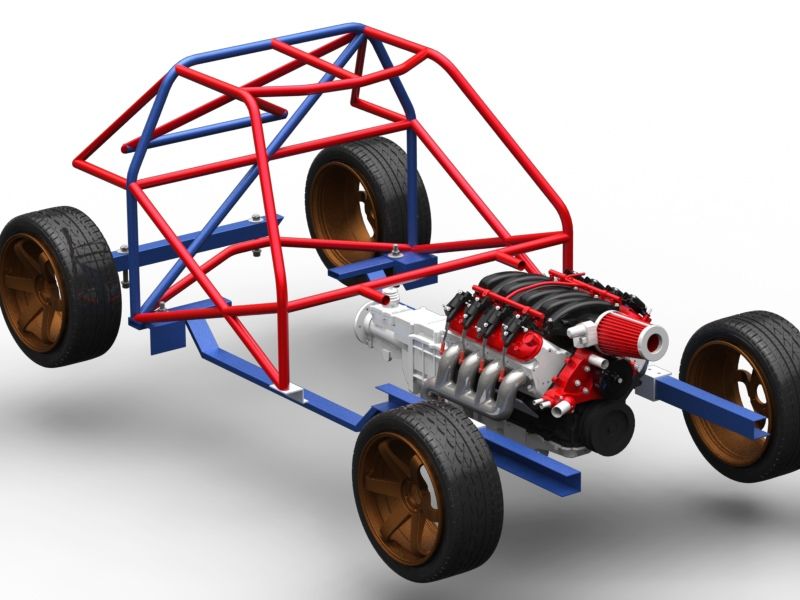

I’ve decided on making a tubular front subframe - anyone have any good reference examples? It will hold my engine mounts, steering rack and control arms.

Obviously not the wheels I will be running, however these 205/60/R16 have the exact same OD as the 275/40/R17 I have at the shop. Someday will be 315/35/R17, but I’ll run the Yokohama 275’s I already have first.

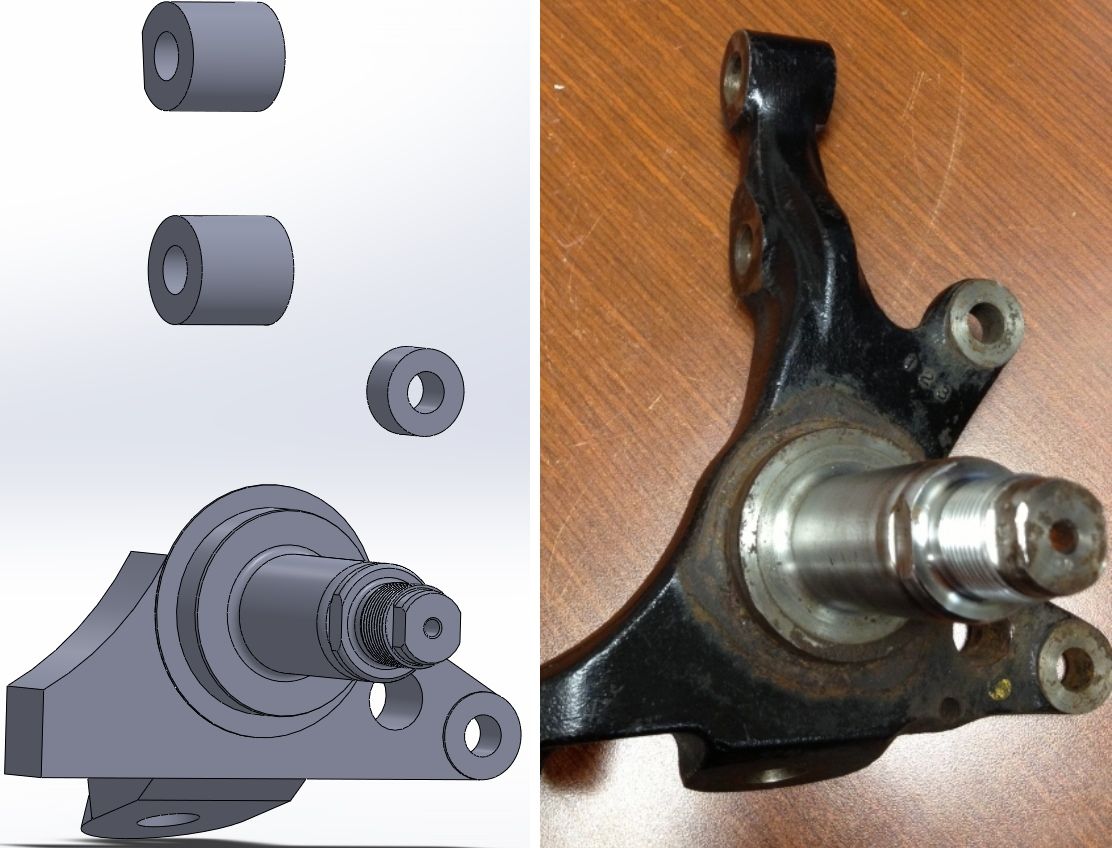

The forward rear control arm mount is at 0 degrees centre of mount pivot to the centre of the balljoint at the ride height shown. This leaves 3.5 inches of wheel travel upwards from ride height once I cut out the wheel well and run extra wide ZG flares

The rearward rear control arm mount is at ~5 degrees from centre of mount pivot to centre of balljoint at the ride height shown.

Suspension experts: Is 3.5" enough wheel travel or am I leaving too much or too little of a gap before hitting tire into wheel well? The optimum parallel RLCA - is this to the front mount or the rear mount of the RLCA?

All arms will be adjustable, but if I have to move my subframe mount up - now would be the time to do it.

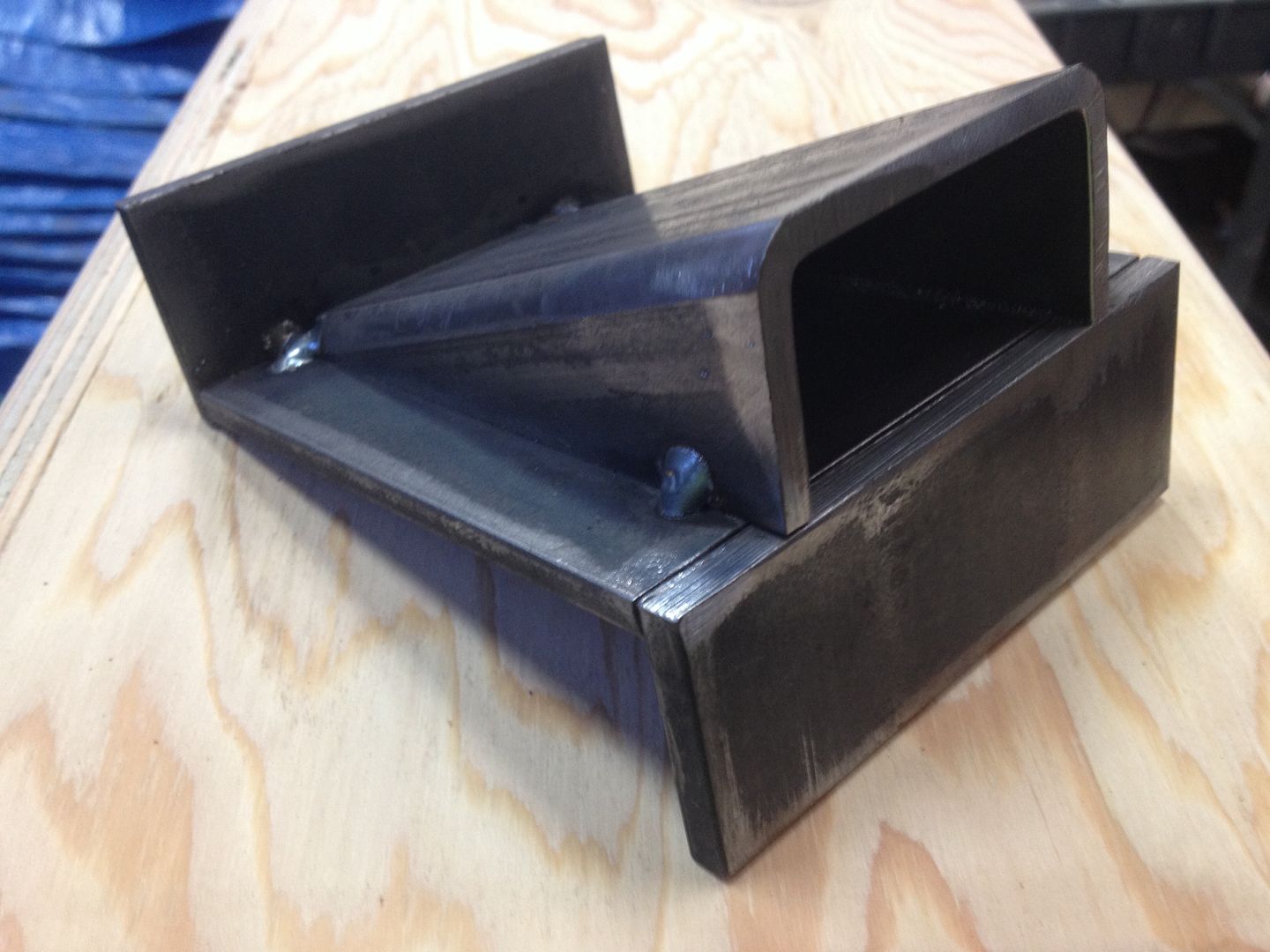

Also, made these braces up - will make the same for the other side of the engine mount bracket all the way to the firewall.

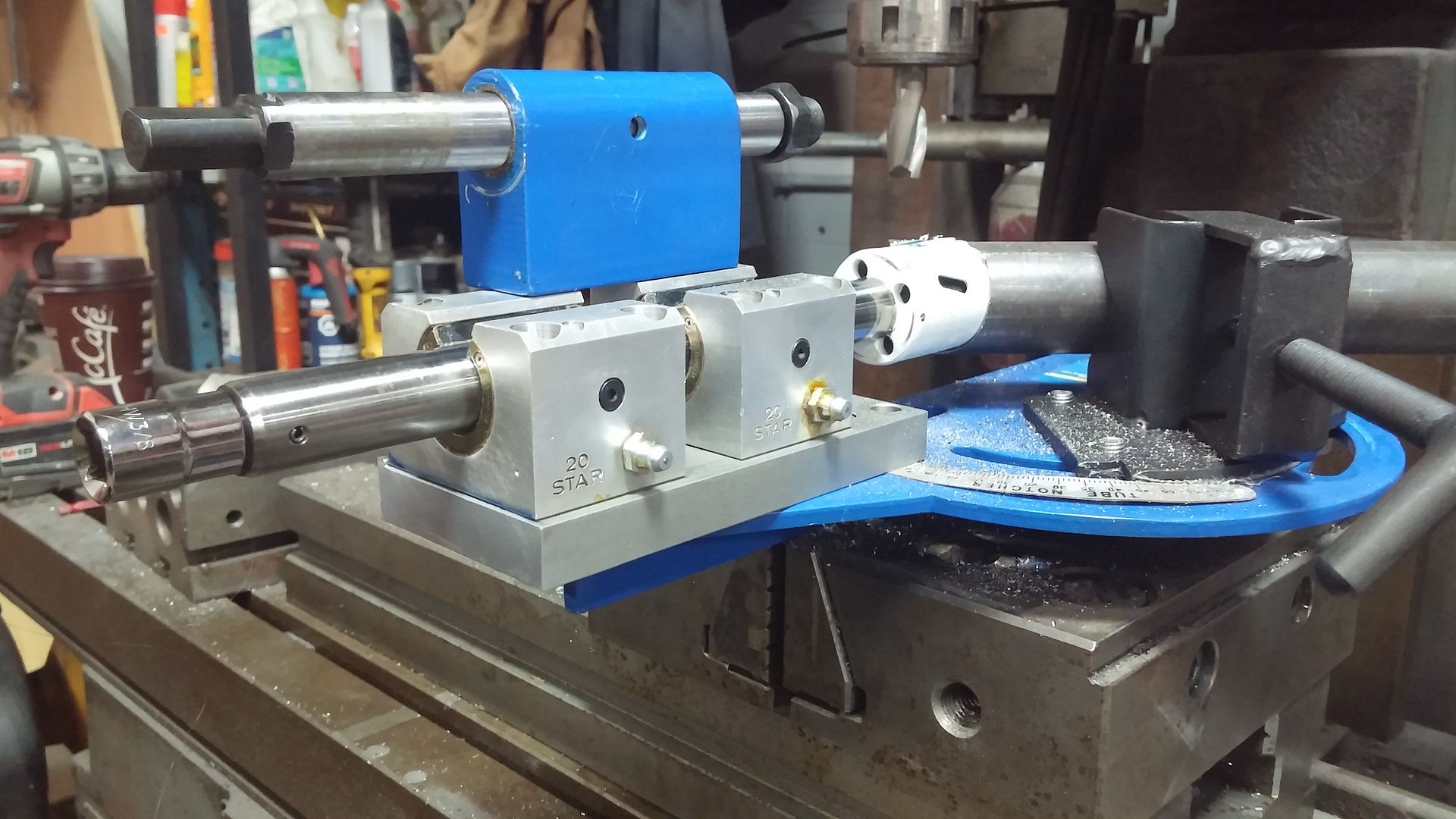

Factory 2012 Camaro driveshaft with the isolator placed where my transmission flange will be:

This means I can cut the second half of the camaro driveshaft off at roughly that weld line and weld a Q45 flange onto it for mating to my diff. I’ll have a U-Joint, Slip yoke as well as the rubber isolator at the transmission output shaft.

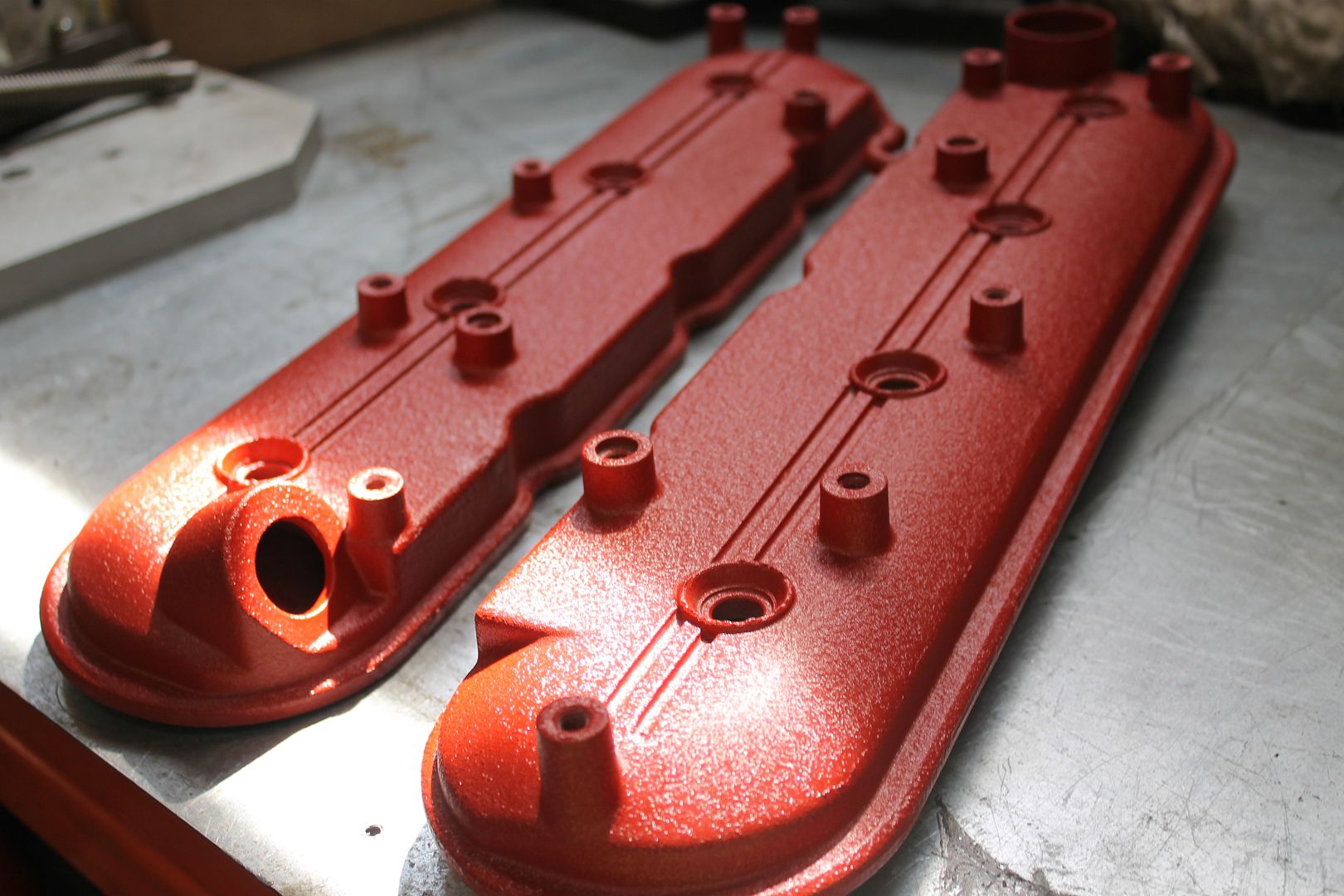

Picked up GM LS7 Lifters

As well as GM LS2 Lifter Trays

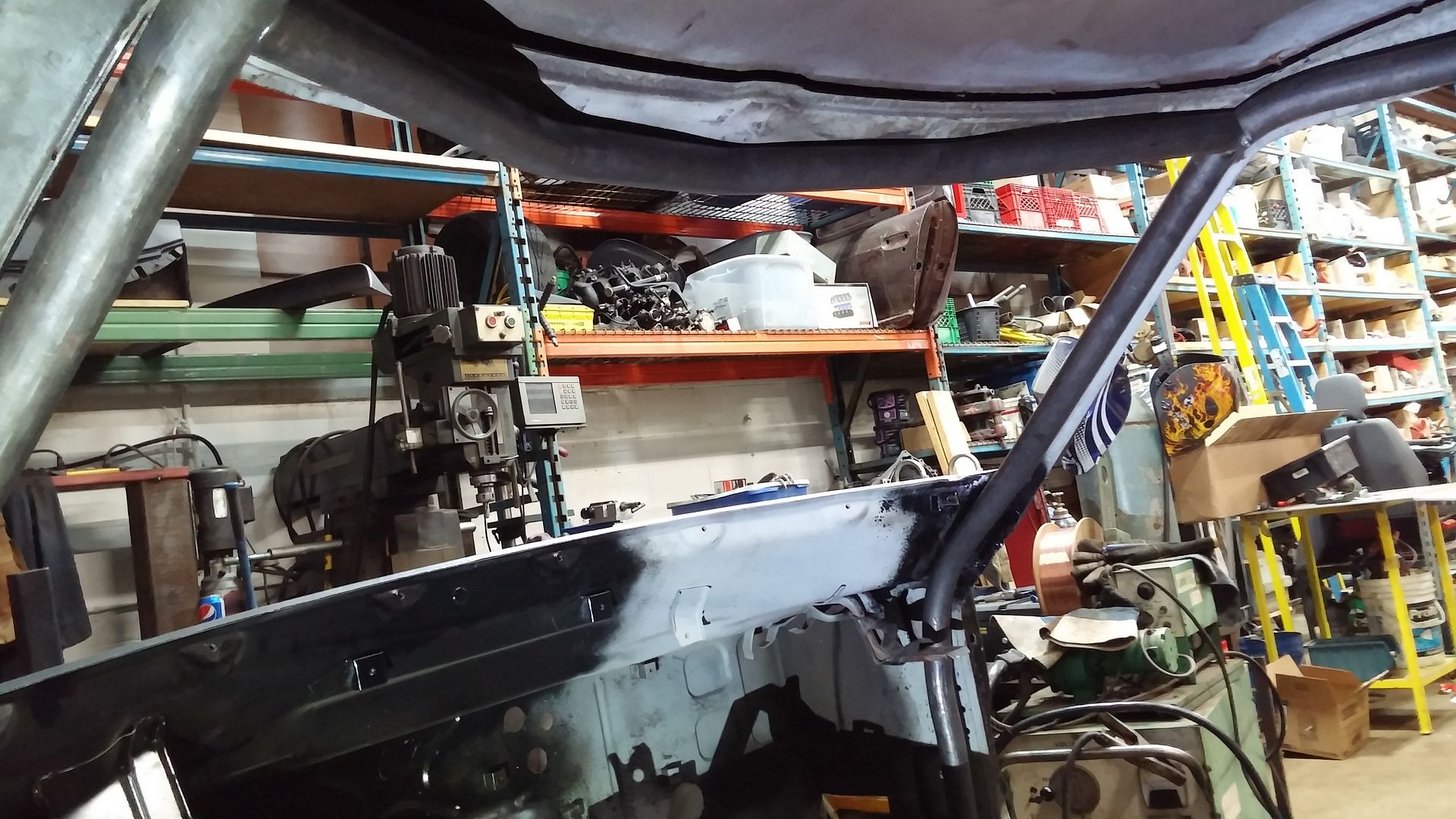

Everything in blue is done.

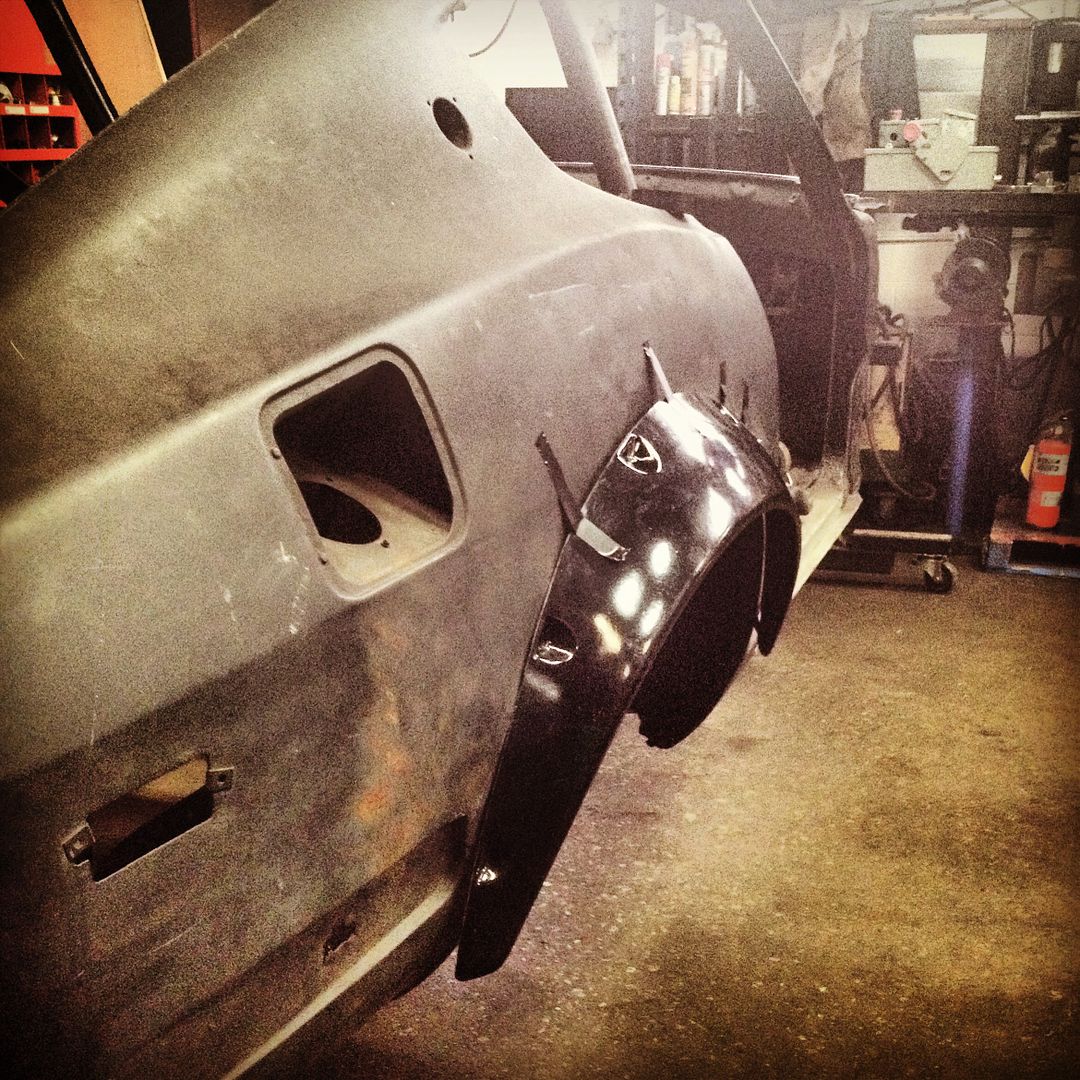

I put the Z back on rotisserie today so if this week I can come to a conclusion about the subframe height I can continue on with the cage.

Also added 2" angle 6" long to brace the factory crossmember where this 1x3 meets it.

Also added 2" angle 6" long to brace the factory crossmember where this 1x3 meets it.