I’m kinda pissed at the Fiero for spinning a rod bearing. In lieu of that, I decided to throw a bunch of money at the 1973 Bonneville 750 I picked up about a year ago. I’m going to be placing a Cognito order fairly soon to get my custom wheelset and triples for the '08 GSX-R 1000 front end I’m putting on. I have a seat on the way along with a bunch of other parts. Of course, an assembled picture:

…and then I pulled the Unit assembly out and lopped the back half of the frame off. Still need to cap the lower tubes with some flat plate and quality TIG time.

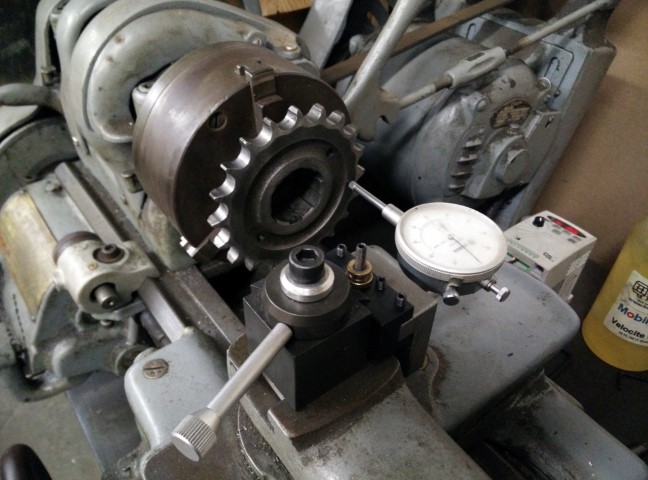

Threw the swingarm in there to get an idea of how things are going to work. I’m swapping the greased bronze pivot bushings for needle bearings. I’m going to powder coat the swingarm black.

I was liking it, so I throw the fork in just for a real rough mockup. I got a steering stabilizer with the fork. I might use it.

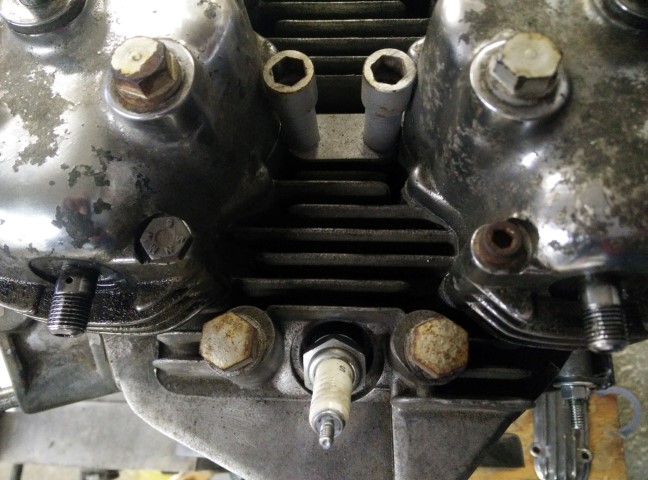

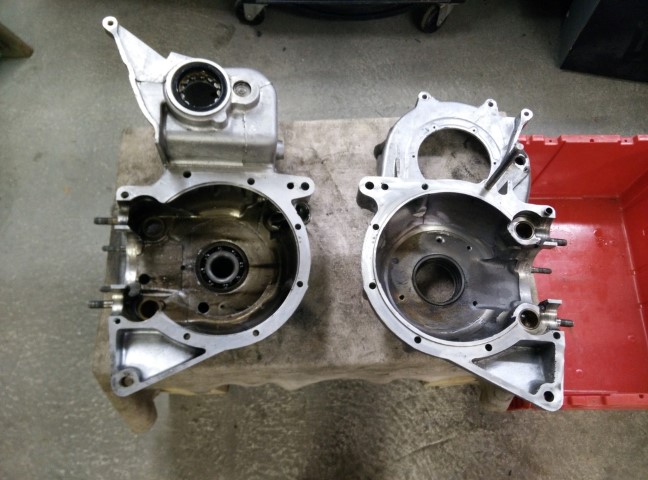

Ideally, I’m trying to maintain tank positioning similar to factory and maybe a slightly lower ride height. I need to get my wheelset ordered and built with the fork properly mounted so that I can measure and make the appropriate rear wheel and swingarm spacers to maintain chainline. This will also give me the opportunity to measure, order and mount my rear shock (hopefully a Penske). That will allow me to make a seat hoop and mount the seat; then mount the rearsets. I’m really hoping to be done in a handful of weeks. We’ll see. Motor doesn’t need much. It ran okay, just smoked a bunch. It’s a fresh .040" over rebuild with new parts. I have all of the receipts for it. I think the rings are stuck from sitting for a few years after the rebuild. I’m hoping. I’m going to pull the jugs off while I’ve got the motor out and see what I see. I thought about ordering one of the LowBrow motor stands. I kind of want to mount it to a Lazy Suzan. Should make my life easy. Fucker’s HEAVY. Anyway, I’ll keep working on this. This is kind of what I’m trying to do. Kind of.