I am looking to rent a 375 cfm air compressor. It is for my business. I’ve called all the local places and no one has them right now. We are looking to try a larger one because our 185 cfm is not quite keeping up the 120 psi of pressure we need. I was thinking someone may have one they are not really using and could get some cash out of it. It would be inside the whole time.

Are you sure those numbers are correct?? 375 cfm would be a diesel powered, monster of a compressor on its own trailer

What are you using it for?

yes, we use it for sandblasting and sodablasting. I found one locally. I’m getting it tomorrow for one week and I think it’s a turbo diesel.

I dont know WTF you are blasting but you would use a compressor that size to sandblast a BRIDGE

Use smaller tips and you wont consume nearly as much volume

lol, the compressors they use are 2-3 times bigger. We actually want to use bigger nozzles. We are blasting these:

and we have 57 more to go! We’re just trying some diferent things to be the most efficient.

WOW, that is nice. i sent a guy from work to see you. He had an avante(?) fiberglass. said it came out great! when i get ready i will be bringing the AWDCRX over for a blasting. (do you have anyone that removes glass)

Awesome, thanks! He was a really nice guy. I don’t deal with anyone directly that does glass but I’m sure there are people on here that can make suggestions.

interesting. How about rigging up a setup where you mount several small nozzles side by side in a row to create a fan pattern for extended coverage"?

like so: X X X X

Actually, I’ve been toying with the idea of making an automated system to blast the sides but I think it would be too involved.

5 long venturi Armex(Arm & Hammer) nozzle with Baking soda(Maintenance XL). These trucks are all aluminum so we do not use sand. It leaves too much of a profile(to rough), and it could warp the surface. The compressor we rented is working excellent I can cover a lot more surface in a shorter amount of time now. It’s still not at 120 psi. but rather @ 100psi. We are constricted now by the air hoses but it is still much more efficient.

I agree, even very fine grit will build a profile on aluminium. Are you using an actual soda blast pot or have you converted a sandblast pot to use soda? We have a decent size soda blaster at work, but don’t use it, mainly blast with black beauty or metal grit. If you don’t mind me asking, what do you spray with, conventional gun or airless?

It is an Armex (soda) pot. We actually do not spray them. They wanted to prep/prime the trucks themselves. Where do you work?

I work for Eastern Tank, I do commercial blasting and linings. We don’t get much call for soda blasting, we usually use black beauty or metal grit. We are thinking of getting an ice blaster, less dust and mess doing structural steel inside of plants/factories.

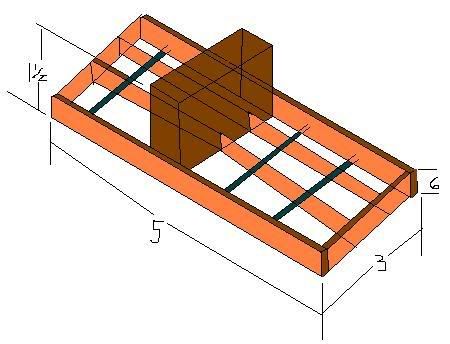

I need this blasted:

More details on the way.

Basically 5x3x1’ in the middle. Rest of frame is 6" or so high. Steel. Nothing fancy, just get the rust off it for me

Weighs approx 100 lbs maybe? Should be real easy and real quick.

I’m going to make my own thread if this was inappropriate, I can delete it.