I want to hear this in real life, so much awesome

If this doesn’t work I’m willing to start a gofundme page for an LS1.

Hah. Four cams > one. It’s simple math.

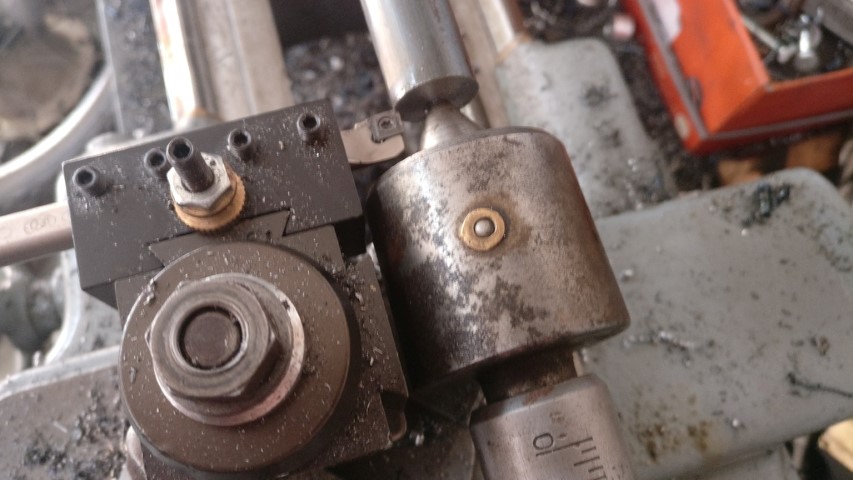

Anyway, I started working on the fuel injector bungs tonight. Chucked up some ~.750" A36 rod in the lathe and got to work. The very first thing I did was turn a short section on one end from which to chuck and indicate in order to somewhat maintain concentricity. I also center drilled both ends.

Set up the machine to face with my 3/8" CCMT boring bar, because that’s all I have inserts left for. I plan to upgrade the toolpost to one of a more appropriate size [larger] as soon as I get moved into the new shop. I’ll post some pictures of that wonderland when we close on the house.

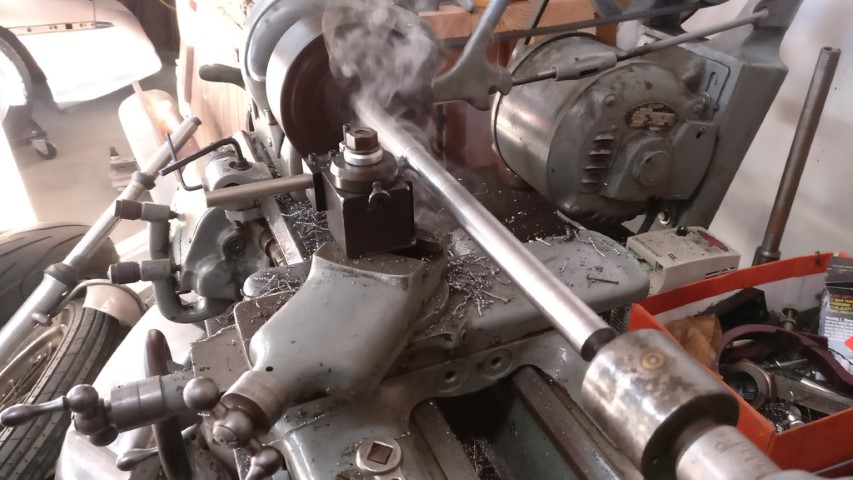

Set up the machine for ~500SFM and .0015 feedrate taking ~.020" cuts to true the rod up as well as get a decent finish.

After I trued up the rod, it was ~.670" or so. Had to hog a bunch off, apparently. So, I drilled and bored to .545" for the injectors.

Can’t really get a decent picture, but I did end up with a very good surface finish on the ID. Much better than with the Dalton on the first set, anyway.

Then I though about it for a second, and the injector input is less than .250" diameter. In other words; there’s no reason for the entire length of the bung to be .545". Only .450-.500" or so depth of .545" is needed, and would actually be beneficial, to better seat the injectors against the intake manifold. I’m not using the factory clips at the rail. I’ll be spending tomorrow evening making 8 new bungs with a .250" main bore and a .450" deep .545" counterbore. The smaller bore up top will leave me with more metal to machine down into a shoulder to press into the rail before welding. Should help with concentricity and maybe even a bit of sealing. If I can get the rails done tomorrow evening and get some paint on them, I can fill all of the fluids on Saturday and see if she builds oil pressure.

Finished those bungs.

I cut shoulders into the tops of the bungs to drop right into the 1/2" holes drilled right into the rail. Based on experience gleaned from the last attempt, I made the bungs 1" long versus ~.6" and I offset the bung holes 1/8" so that I could have a bit more room for the mounting bolts. They’re all spaced an even 4" apart.

Bungs fit. Just need to weld those on, cap the ends of the rails, drill the ends for the -8AN bungs and weld those on. Hopefully finish all of that up Saturday morning. I’m working all day tomorrow, unfortunately.

Didn’t get a chance to get over this weekend at all. Kinda bitter about it, but oh well. I managed to get over there today and finish welding up those rails.

Plenty of clearance for the retention bolts now and the regulator input is finally on the front rail as it should be. I’m pretty happy with these ones. I’ll hopefully be getting over there tomorrow to pressure test them and get them painted.

I’m also going to try to get the fluids filled and see if she’ll build oil pressure. Maybe even get her fired if there aren’t any major issues.

Looking great man. Its really coming together quickly. :tup:

Thanks! I’m trying to get over there almost every day now. It’s sometimes a bit inconvenient that I live almost a half hour away from my parents’ house with the shop. My girlfriend and I should be closing on our house in the next week or two and it’s got a beautiful ~40’ x ~24’ steel building with two overhead doors and two man-doors on top of a ~6" slab. Not sure about steel reinforcement in the slab, but I suppose I could borrow a metal detector or maybe use a decent stud finder? I’ve heard that’s a good strategy sometimes. Unfortunately it’s not currently insulated or wired for 220V, so I’ve got a bit of work to do before winter but I really can’t complain. Pretty stoked.

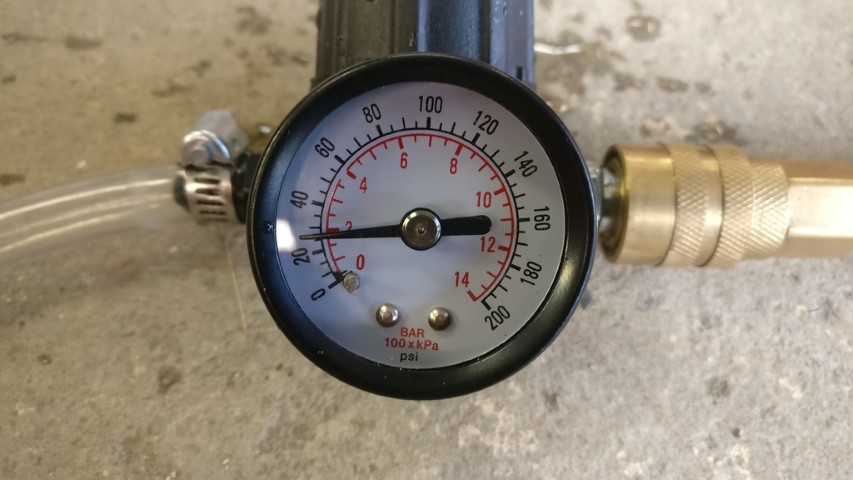

I stopped at my favorite store after work to grab a cheap air regulator and I got to pressure testing those rails.

Not a single bubble from either. Unbelievable. Just need to make some mounting brackets, weld them on and paint the damn things and they’re done. Rad.

I also filled the transmission and the engine with oil. Then I tried to crank it and the battery was stone dead. I just it with my Subaru and got it to crank a bit, but then I realized that the harness I used sourced gauge power from an accessory feed, so I lose gauges during crank. Maybe I’ll hot wire it tomorrow. Good news is that it cranked over without too much ado and no bad noises. Awesome. I left it on a battery tender overnight to recharge it.

Umm. Figured out my battery issue.

Cool story. Guess I have to stop by Advance tomorrow and grab a TX30L, which is effectively a Deka ETX30L, and has 26Ah reserve capacity and 400CCA. That battery is about an inch less wide, but it’s a quarter inch deeper and a bit taller. Either way my battery box was not going to work as it was, so I cut it up and wire wheeled it so I can re-box it tomorrow with clearance for the new battery. That was disappointing to see. Oh well.

I also measured the angle of the injectors so that I could properly make some hold-down brackets for the rails.

Still haven’t finished them, but that’s first on the list tomorrow afternoon when I get there. Then battery tray/battery will come afterward and I might be able to get it fired up Friday.

Looking good fool. I expect to see this thing sideways on the little “loop” by your folks house. Set it up just right and you can drift that 90 degree turn and just power out on the straight.

Don’t break it so quick this time so you can finish the Triumph. I’m equally (more) excited about that.

Hah! I think I’m more prepared this time. This is by all measures a vastly better motor and I reset the hard rev limiter to 7K. I also got the balancer torqued on properly so that the oil pump drive sleeve is actually properly engaged. For some reason GM didn’t think it prudent to use a key between the crankshaft and oil pump drive sleeve. The only thing that forces the sleeve to spin with the crank is the torque from the bolt sandwiching the sleeve between the balancer and a shoulder machined into the crank. Arguably the most critical part of the motor is driven by friction. What the fuck, GM?

I’m going to try and tie up all of the bullshit loose ends tonight and fire it tomorrow. I’m off until next Wednesday so I can get some seat and clutch break-in time in, hopefully.

Speaking of the clutch. I bled the hydralics and I’ve got to say; it doesn’t feel a whole bunch stiffer than the previous setup, which was a ~2,300lb Clutchnet pressure plate. Feels good. I’m pretty excited that’s worked out so far. Definitely should have done that in the first place a bunch of years ago, but I wasn’t capable.

I’ve been working on this car for over 10 years, with the vast majority of current work being done in the last 2. It’s amazing to me how much of my old work I feel the need to redo as well as pondering about how I would have accomplished some of the current things back then. It’s pretty satisfying to me to recognize that personal growth.

Good deal man, looking forward to gnarly burnout vids.

Speaking of which, while I am nowhere near your skill level or tool access, i’ve noticed a lot of my old work as inferior and redone some recently. Feels good for sure.

PS, that gold Honda CB450w/inverted front end I attached from your triumph thread is MY bike. ![]()

Nice! That’s rad.

I stopped and grabbed a battery from Advance. It’s essentially a rebadged a Deka ETX30L, but with slightly different terminals. It’s $105 shipped online, and $136.99+tax in store. I managed to get it for $115 out the door and it was local, so I had it today. Perfect.

So then I replaced the angle that I cut out of the battery tray yesterday. I decided to use a J-hook for the rear hold-down and a large wingnut on the front. Much moar better.

Spins this 10.5:1 compression V8 over with ease. Granted, it’s relatively small at 4L, it’s still satisfying that it works so well. Just need to finalize battery cable routing and attachment.

Then I got back to the rails. I took a couple pictures of the mockup, but then I got distracted with welding and rushing so that I could head back home for some dinner and I forgot to take pictures after that. I’ll get some more tomorrow before I paint them. They were still pretty hot and I need to clean them really well, so I saved that for tomorrow morning.

Not the most helpful or detailed photos, but they give you an idea of what I’ve done. I also triangulated the outer edge back to the bottom of the hold-down clamp with some 1/4" rod. Mainly for aesthetics.

I’ve only been able to work on it like 2-3 hours a night. Can’t wait until I actually live at my shop and can work until 2-3A without any hassles.

I’m firing it tomorrow.

So is it just me or has photobucket stopped working for everyone?

Nope, he went over his free bandwidth quota so we’re all getting the error message instead of pictures now. ![]()

What the fuck? I’ve been using Photobucket for like a decade! It looks like they recently decided to stop allowing any 3rd party hosting for free accounts.

Hmm.

Well. I’m certainly not paying for 3rd party photo hosting.

I wonder how much actual bandwidth I would be using if I decided to set up a quick ‘n’ dirty HTTP server here with my domain and host my own photos? I have been thinking about it for years, just never needed to what with Photobucket being so easy and free. I’ve got Spectrum here. No FiOS available. Sad face.

Looks like I’ve got another project for this weekend.

Within the last few days, Photobucket decided to remove any and all 3rd party hosting ability from all but their most expensive monthly plan, which is $40/month. They updated their terms of service to reflect this without requiring users to agree to the new terms, or even notifying users of said updated terms. Seems to me, they pretty much just sealed their fate.

Why would a company want to piss off the entire internet?

x2 they are sunk

Alright. I set up my own webserver for testing.

Is that working for everybody? I just need to resize before posting. Also seems to be okay speed-wise. Yes? No?

EDIT: Just tried to go back and edit my previous posts here and when I click ‘EDIT’, I get a blank window. Like, it doesn’t bring up the text in the old post so that I can just edit the IMG tags and restore this Photobucket clusterfuck. Am I doing it wrong?