Did a bunch today.

Started with scrubbing the studs/nuts/washers and baking then dry. That shop oven might be some of the best money I ever spent on a tool. I think I paid $50?

Applied LocTite and threaded in each stud.

Dropped the head gasket and head on and torqued the nuts down. I was a bit gunshy, but no stud issues whatsoever.

…and the other side. No issues here either. All 20 nuts to 75ft/lb with no incident. Stoked on that.

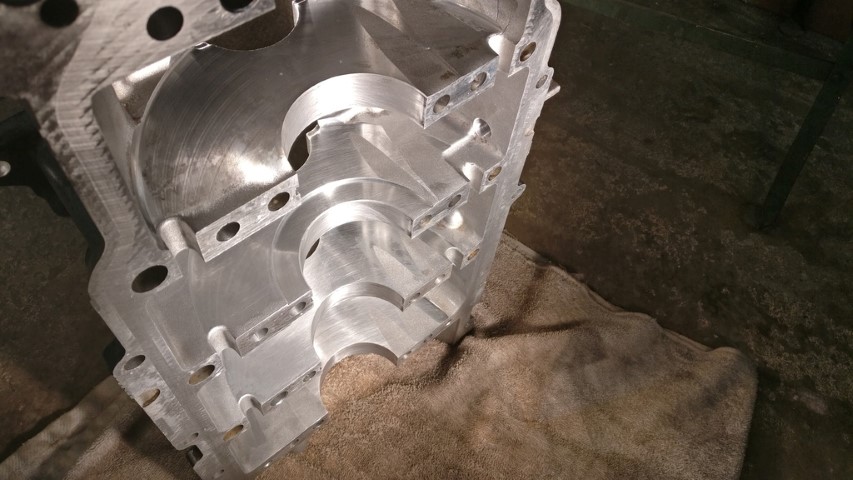

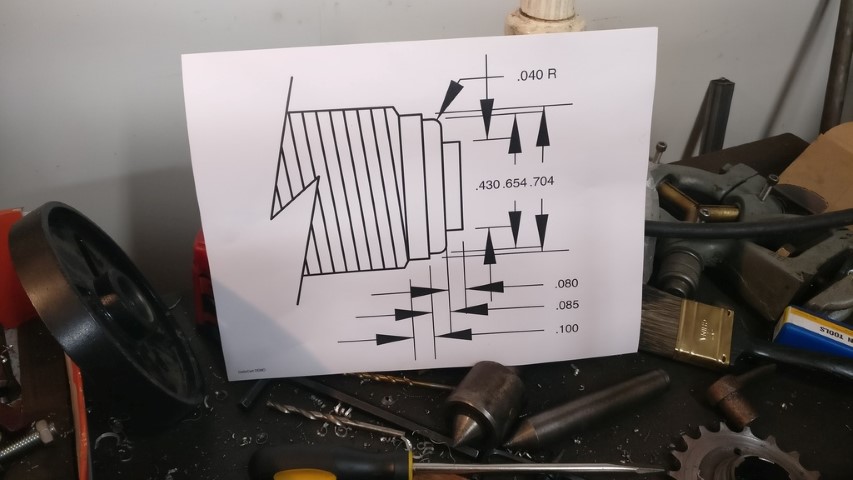

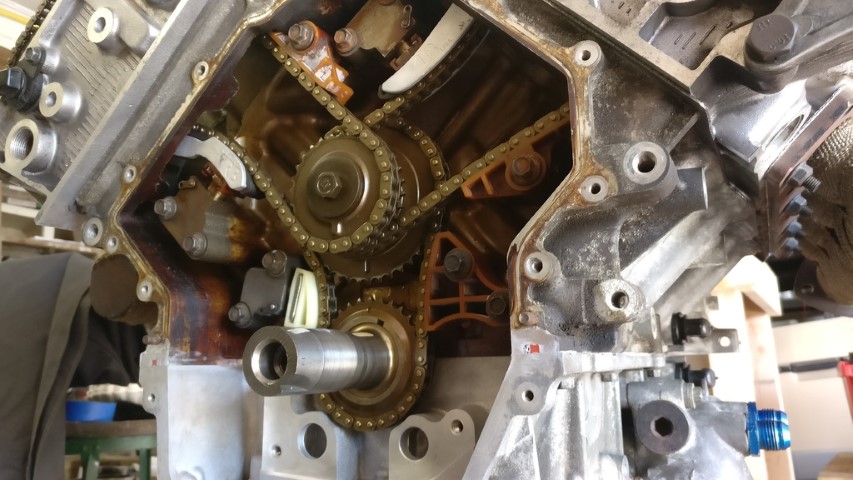

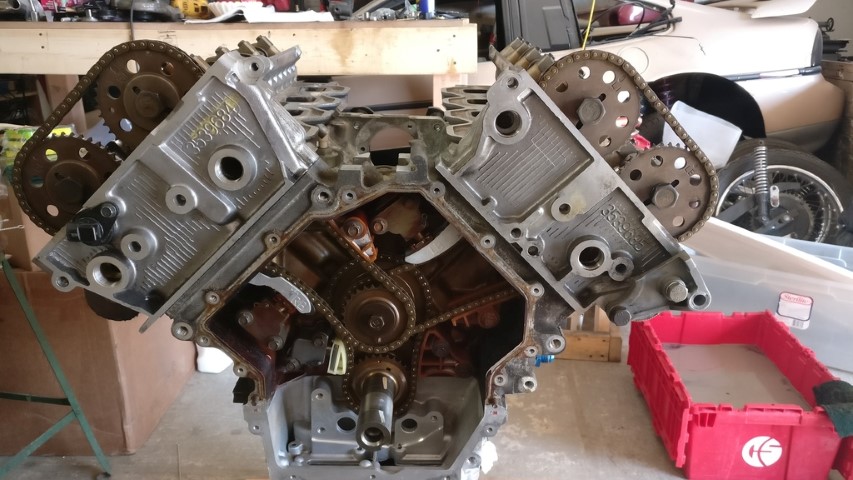

So, now that the bottom end is nicely resealed and the heads are back on; I continue assembly with the timing system. First, though, check out this cross section of the crankcase half seal. Sure looks pretty ideal to me. Orange is the OEM rubber seal, gray is Permatex Ultra Grey.

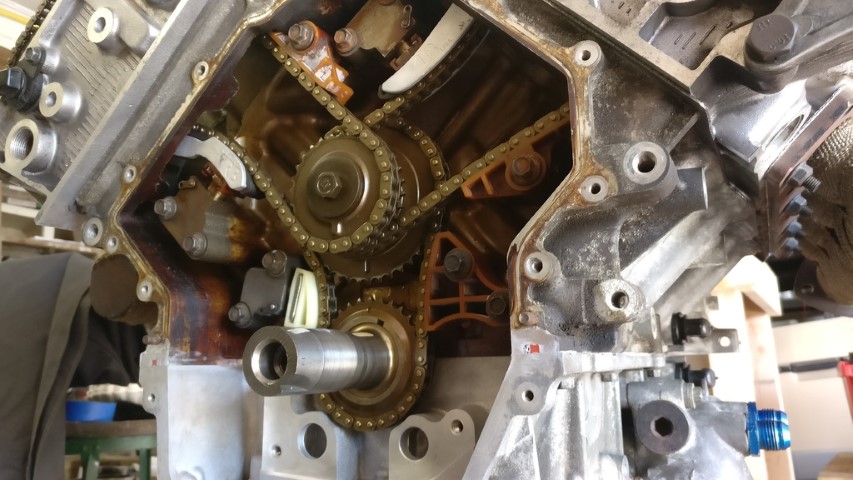

Here’s the fully assembled timing system ready for the cover. I did clean the flange before assembling with the seal.

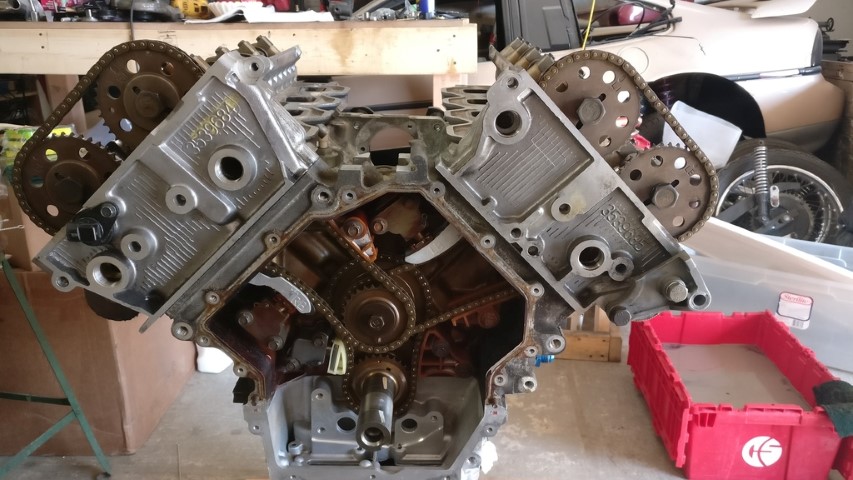

This motor is fucking yuuuuuge with the heads on. I love it.

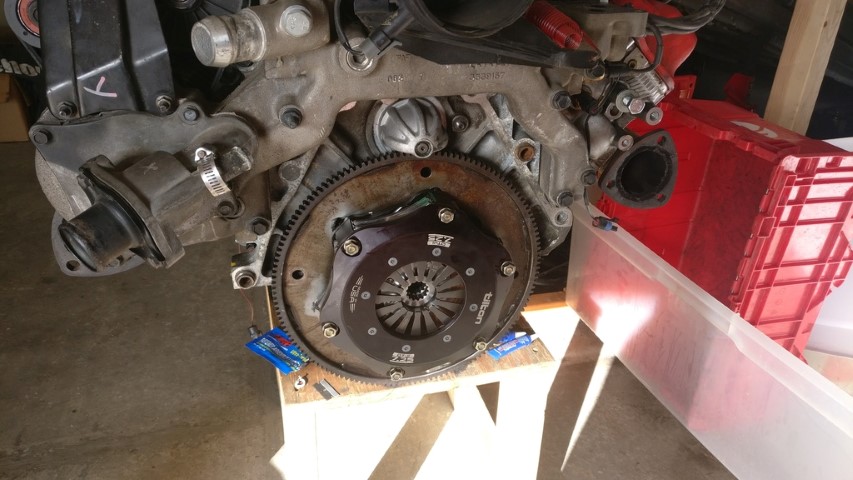

…and a bunch of bullshit later; a mostly completed motor. Can definitely finish that tomorrow.

So, now that the motor is almost ready; I need to get that leaky ass transmission out. Looks like almost a half quart lake on the shop floor.

So, I lifted the ass end to get the cradle out.

…and then I drained the trans, which actually still had what appeared to be two quarts in it. Popping the axles out and pulling the trans off the cradle came next. Wrestled it onto the bench so I could tear it down.

Found a bunch of interesting things in the trans, like this bearing missing a roller.

…and said missing roller was stuck to the magnet at the bottom of the case.

I can’t really explain that. There doesn’t appear to be any brinelling or other visible damage to the outer race, so I don’t really know what was going on there.

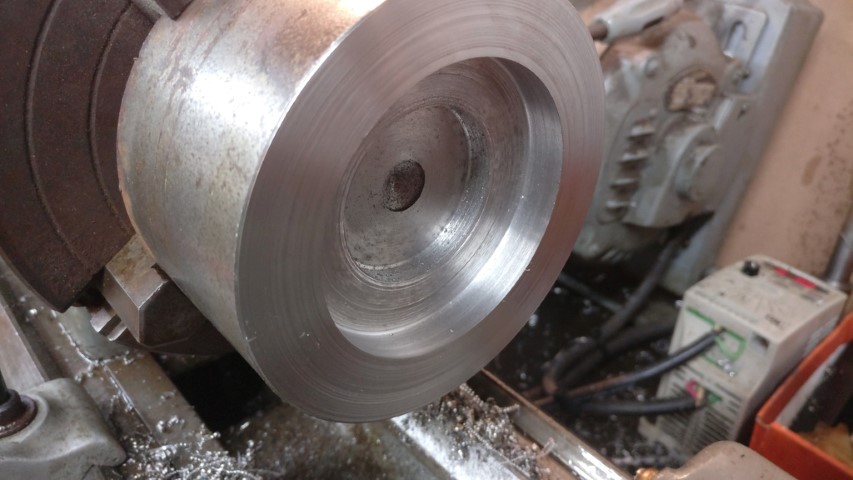

There is also a shit-ton of a sort of paste formed by the ATF and metal powder. It’s all extremely fine, like literal powder; so I’m thinking that stuff is from the new differential wearing in, lapping all of it’s gears against themselves. I’ll wipe all of this garbage out and refill with fresh ATF. The factory fill point in the trans is inaccessible when bolted to a Northstar, so I need to add a secondary fill point, or just pull the shifter mechanism. I shouldn’t have to be adding fluid frequently, if I can get the damn thing to stay sealed.

Heading back in the AM. If I play my cards right, I might be able to have the motor back in the car. Not functional, because I still need a few parts and to make a new set of fuel rails, but I can take care of that minutia this week. Gonna drive it this weekend. Fingers crossed.