earlier GSXR are individual TB’s racked together. guys that do ITB’s on the mk1 ford focus use them and just use threaded rod and lock nuts to space them to the stock lower intake manifold with couplers. like 01-03 I think.

No, just don’t want to see you waste your time…

The TBs that were recommended to me were from a '98-'99 GSX-R 750, I think? Dudes seem to think they’re made of gold, asking $100+ per set. These 06-07 GSX-R TBs would work, but I don’t love them. I still might spend some time shaving them for a possible future application, but they’re getting shelved for now.

Coincidentally, I found these Triumph joints that are perfect. They’re from a ~2001 TT600. They don’t have a whole bunch of extra junk on the casting, they don’t have secondary throttle butterflies and they’re individual units. I spent $35 on a set of those to check them out. There are only two small caveats, and they’re not really a big deal. One is the lack of injector bungs machined into the TBs. I’ll just put bungs directly into the runner behind the butterfly. The other thing is the lack of vacuum ports on the TB, but again; those can be pulled from the runners.

These might be better, but they’re from a British 3-cylinder, so I’d need three sets, and these are $100-$150 per set from the UK. They truly are perfect, though. Hmm.

I am the emperor of wasted time.

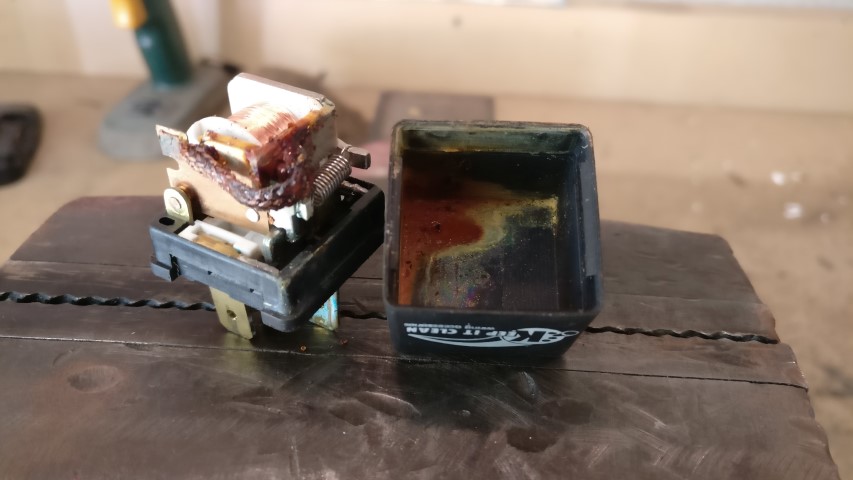

Got to the bottom of that horn issue.

I replaced it. Horn is back. It’s glorious.

Also, that was inside the car. I’m pretty sure I know how it happened, I guess I just didn’t realize that the horn relay was corroded all to hell. It was intermittent last summer, but I just chalked it up to the horn button. I took that apart today and it was immaculate. It was the relay the whole time. Horn is nice and strong, now.

Trying to come up to Cars & Coffee in the morning. Am I welcome to park in the show lot?

pictures no werky!!

Working for me?

Interesting. How about now?

Yea, they’re working here too. Mobile and work computers are both good.

I suppose I should start updating the links in the Triumph thread.

Yes sir! what was it?

Hah. No clue. Didn’t do a thing on my end.

So, I got those Triumph throttle bodies. I think they’ll work alright. There’s a bunch that I like about them and a few things that I really don’t care for.

Things that I like include symmetry.

That is three of the four bodies. They are effectively identical, save for one butterfly shaft boss that is approximately .250" longer than the other two, illustrated below. Fortunately it’ll be on the underside of the intake, so not a deal breaker.

Hopefully, I’m able to shave that back on the lathe and then they can all be identical.

The fourth body is another story. It’s got a large, awkward boss cast into it for the TPS, which I don’t need. It’ll be tough to get rid of, so for the price; I’ll just get a third set of bodies and use the inner two for the fourth in each set. I love symmetry.

So, the bodies will be rotated 90° such that the butterfly shafts are vertical, yet perpendicular to each other. I’m basically replicating that Kinsler LS setup at this point.

Of course there is some that I don’t care for.

These are 37-38mm Mikuni bodies. They measure 37mm and change, but there’s a ‘38’ stamped on one of the bodies somewhere. Who knows? Either way, that’s a bit small, so I’ll bore them out to 40mm on the lathe. I’ve got those 40mm throttle plates from the GSX-R Mikunis, so I’ll just steal those I suppose. Less work than making new ones, anyway. That’s for true. The retention bolt holes even almost line up perfectly. Minimal work with a file there, if anything.

The last two photos indicate the lack of diametric clearance for the 40mm plates in the Triumph shafts. This should be easily remedied by a thin file or blade. The slot is for all intents and purposes .063" thick - perfect for the GSX-R blades, but I need approximately .033" extra width on each side [total .065"] to clear the larger blades.

Speaking of the butterfly shafts, they’re 8mm versus the GSX-R’s 10mm. I don’t really mind one way or the other, but 8mm has a smaller profile. A 40mm bore with a 8mm shaft through the center of it will flow more than the same bore with a 10mm shaft.

Right now the shafts ride straight on aluminum bores drilled directly into the TB, with rubber seals on each end. Instead, I’ll counterbore and ream the shaft bosses such that they’ll accept 8x12x8 metric roller [Torrington] bearings. I found bearings in a closed flavor which will go on the lower, non-servo horn end of the shaft to enclose it, as well as the standard pass-through type bearing for the top boss. This might help illustrate.

Right now, there’s an 8mm bore for the shaft and an 11.3mm counterbore that’s 3.3mm deep at the opening of the boss. That counterbore will need to be extended to at least 8mm deep and widened to just shy of 12mm for the bearing fit. If I can find sealed units that would be great, but I may need to add a slight amount more depth to the counterbore for a small seal if not. I might as well incorporate a seal, if I’m going this far.

The new TBs are 2.925" long as opposed to ~3.5". So, that combined with the 4" head runner length give me a new length of 7". I’ll need 7" transition runners between the intake flanges and TBs. Good deal. The only issue there is that means that I don’t have any extra length at the openings of the TBs for velocity stacks or trumpets of any kind. We all know how beneficial round transitions in intake tracts are.

There’s a nice, meaty lip on these guys. So, what I think I’ll do is turn the diameter down until I lose the chamfer on the outside of the TB. Then I’ll press on a 6061 ring with sleeve retainer that’ll give me an overall .500" lip width and a ~.250" depth. Basically, it’ll allow me to machine a 1/2" half radius directly into the opening of the TB so I can have a trumpet without any additional length.

I might draw up and have a flange cut from 3/8” or 1/2” 6061 soon-ish so that I can start to get an idea of how this is going to come together.

I got those stepper motors, but I’m not sure that I’ll use any of them for this project. Now that I’m using different throttles in a different configuration, I think that I’ll just use a single large NEMA23 motor to actuate both banks as they can have ~4Nm of torque direct and are more robust. I’m thinking about cutting a 1/2"-10 ACME worm gear and then hobbing my own matching 52T worm wheel to make up a 52:1 reduction. That will drive a ~1:4 speed increaser for an overall ~13:1 reduction, allowing for ~50Nm holding torque on the shaft actuating the butterflies. Still waiting on the stepper driver ICs for the Arduino.

I’ve got all of the parts to make the two linkages required to link the banks of throttles together on the bell crank.

Hah. No clue. Didn’t do a thing on my end.

So, I got those Triumph throttle bodies. I think they’ll work alright. There’s a bunch that I like about them and a few things that I really don’t care for.

Things that I like include symmetry.

That is three of the four bodies. They are effectively identical, save for one butterfly shaft boss that is approximately .250" longer than the other two, illustrated below. Fortunately it’ll be on the underside of the intake, so not a deal breaker.

Hopefully, I’m able to shave that back on the lathe and then they can all be identical.

The fourth body is another story. It’s got a large, awkward boss cast into it for the TPS, which I don’t need. It’ll be tough to get rid of, so for the price; I’ll just get a third set of bodies and use the inner two for the fourth in each set. I love symmetry.

So, the bodies will be rotated 90° such that the butterfly shafts are vertical, yet perpendicular to each other. I’m basically replicating that Kinsler LS setup at this point.

Of course there is some that I don’t care for.

These are 37-38mm Mikuni bodies. They measure 37mm and change, but there’s a ‘38’ stamped on one of the bodies somewhere. Who knows? Either way, that’s a bit small, so I’ll bore them out to 40mm on the lathe. I’ve got those 40mm throttle plates from the GSX-R Mikunis, so I’ll just steal those I suppose. Less work than making new ones, anyway. That’s for true. The retention bolt holes even almost line up perfectly. Minimal work with a file there, if anything.

The last two photos indicate the lack of diametric clearance for the 40mm plates in the Triumph shafts. This should be easily remedied by a thin file or blade. The slot is for all intents and purposes .063" thick - perfect for the GSX-R blades, but I need approximately .033" extra width on each side [total .065"] to clear the larger blades.

Speaking of the butterfly shafts, they’re 8mm versus the GSX-R’s 10mm. I don’t really mind one way or the other, but 8mm has a smaller profile. A 40mm bore with a 8mm shaft through the center of it will flow more than the same bore with a 10mm shaft.

Right now the shafts ride straight on aluminum bores drilled directly into the TB, with rubber seals on each end. Instead, I’ll counterbore and ream the shaft bosses such that they’ll accept 8x12x8 metric roller [Torrington] bearings. I found bearings in a closed flavor which will go on the lower, non-servo horn end of the shaft to enclose it, as well as the standard pass-through type bearing for the top boss. This might help illustrate.

Right now, there’s an 8mm bore for the shaft and an 11.3mm counterbore that’s 3.3mm deep at the opening of the boss. That counterbore will need to be extended to at least 8mm deep and widened to just shy of 12mm for the bearing fit. If I can find sealed units that would be great, but I may need to add a slight amount more depth to the counterbore for a small seal if not. I might as well incorporate a seal, if I’m going this far.

The new TBs are 2.925" long as opposed to ~3.5". So, that combined with the 4" head runner length give me a new length of 7". I’ll need 7" transition runners between the intake flanges and TBs. Good deal. The only issue there is that means that I don’t have any extra length at the openings of the TBs for velocity stacks or trumpets of any kind. We all know how beneficial round transitions in intake tracts are.

There’s a nice, meaty lip on these guys. So, what I think I’ll do is turn the diameter down until I lose the chamfer on the outside of the TB. Then I’ll press on a 6061 ring with sleeve retainer that’ll give me an overall .500" lip width and a ~.250" depth. Basically, it’ll allow me to machine a 1/2" half radius directly into the opening of the TB so I can have a trumpet without any additional length.

I might draw up and have a flange cut from 3/8” or 1/2” 6061 soon-ish so that I can start to get an idea of how this is going to come together.

I got those stepper motors, but I’m not sure that I’ll use any of them for this project. Now that I’m using different throttles in a different configuration, I think that I’ll just use a single large NEMA23 motor to actuate both banks as they can have ~4Nm of torque direct and are more robust. I’m thinking about cutting a 1/2"-10 ACME worm gear and then hobbing my own matching 52T worm wheel to make up a 52:1 reduction. That will drive a ~1:4 speed increaser for an overall ~13:1 reduction, allowing for ~50Nm holding torque on the shaft actuating the butterflies. Still waiting on the stepper driver ICs for the Arduino.

I’ve got all of the parts to make the two linkages required to link the banks of throttles together on the bell crank.

Closing on the house on Monday, hopefully. I’ll be back to work on the Triumph in September after I take care of some infrastructure projects for that.

Just an update here, I suppose.

Been driving the hell out of it.

Decided to head up to Empire last night with my buddy Trevor and his STi. First quarter mile runs I’ve ever taken. I now see why people love this.

Here are my first two runs. Ever.

…and my best run of the night.

I’m pretty happy with how it did. Spun a bunch off the line, so I think I can clean up those 60ft times with some better traction.

…but apparently after 5 runs, I pushed my luck too far.

Absolutely destroyed the inner tripod on the axle that I just replaced last summer. Hmm.

It made some awesome noises.

Ordered replacements axles. Should have her back together this week.

Love this stupid car.

Damn that bitch moves!

Yea, I was pretty impressed. My highest trap speed of the night was 102.48. Pretty decent. I never trapped less than 100. I’m happy with that 1.96 60’, but that could be better. I think by as much as a couple tenths with just a driver mod and radials.

Somebody once told me that every tenth you can take off of your 60’, that’s two tenths off of your ET. IF I can manage to pull a ~1.7-1.8 60’, I might be able to hit 12.9s. Maybe.

But I need to get those axles in first.

Tech guy at the front of the staging lanes gave me all kinds of shit for the missing decklid. Almost didn’t let me run. Funny, the guy that assigned me my number didn’t say anything.

It was definitely a hell of a lot of fun.

Cool. Glad you were able to run it. My buddy and I are heading down Friday.