word… hopefully that will do it

yeah but then you have to get a full refund I believe… if the guy is smart he will settle up

keep in mind the thickness of the material used in the framing supports for the rear is thinner factory than in the engine bay. not necessarily the the wheel arches but the bulkhead rails themselves.

hey mike… make sure the clutch hes sending you is in working order and not the one he said was busted

I wasn’t aware that they are thinner, but the way I plan on reinforcing them should prevent that from being an issue anyway.

right, I’m on it.

it looks like I’m going to have to adjust my plan a bit, simply reinforcing the rear frame rails won’t do. I won’t be able to squeeze the motor and trans between the frame rails the way they are right now.

I’m working on creating a pace that will weld into the existing rail but give me a few extra inches between them right where I need it.

Cuts were deliberately done wide with an inch or two of excess to be trimmed down and cleaned up later.

Would explain some of the box frame of similar builds you sent me photos of.

Where are the mount locations for the UCA’s and LCA’s that you sent me(I did get that email)? Affixed to a portion of those rails, or elsewhere on the unibody? That could be a little pickle there.

That guy in Roc you mentioned in past discussions doing the frame work, does he have a layout table?

I think the other people did it primarily due to the rear subframe being almost on the axle line. Something that i’m not worried about due to the suspension configuration I am planning.

The trailing arms get tied in by the tow arms underneath where the hoop of the roll bar gets tied into the floor, and by the camber arm which gets tied in farther back on line with the subframe.

neither should be a problem for the 12" or so that I need it widened.

and no, he does not have a layout table.

Yeah just took another look at those photos you sent me after posting and agree non-issue.

I’ll let you know when the parts arrive here. Will give you a call so we can discuss stuff over the phone vs emails.

yep. Will do.

If you havent bought a tranny yet just get the fg si tranny. Comes with the same lsd that the type-r has. HAs a 4.7 fd and great gearing.

I really like that option, but I can get two Type-S trans for the same price. With a LSD only $400 or so I don’t get where the extra cost is.

I still thinking about it, I’m going to need one at least for mockup very soon.

So apparently Honda has discontinued the left trailing arm that I need but not the right… go figure.

I guess I’m going to have to contact junkyards now to try and find a pair.

Mike, please get that Cannibeat sticker off the engine asap :rofl

Is cannibeat some type of superstreet thing? The previous owner was definitely a retard.

I’m not going to waste my time removing it until I’m done scratching up the motor with the hoist chain and I’m ready to powder coat it

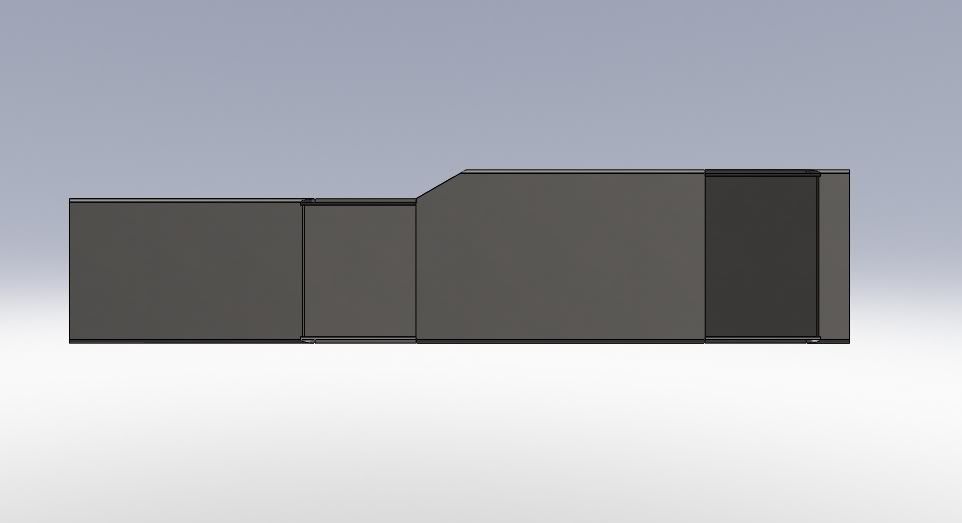

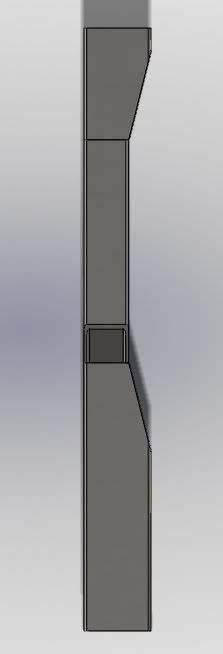

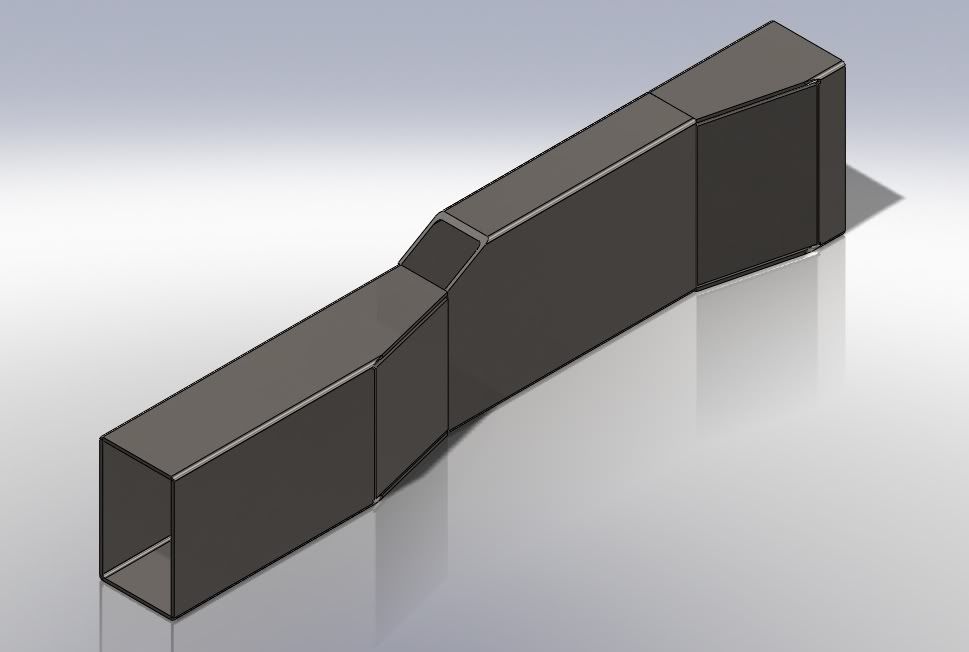

As far as widening the frame rails a bit, my current thoughts are to cut out the inside wall of the frame and putting this in there. Its different widths/heights of 11ga rectangular tubing.

The new bit of frame would be mig welded together and then mig’d into the existing frame.

Any thoughts?

If we tie it into the cage, not an issue at all. Actually good to retain some of the unibody if we’re not doing a complete tubular rear chassis and cradle. It’s one way around the problem, definitely the easiest/cheapest route.

I’m going for simple. We could cut into this thing all day if I wanted to go nuts with it, but I really want to to retain as much of the factory metal as (reasonably) possible. I have some sketches for a few other components that I’m going to model up and work with. I’ll post them when I’m done.

I know how that goes. Was contemplating gutting the rear framerails on the subaru(rusted a bit) and just tubing the whole back end. Just did a small “cage” reinforcement around the cell instead.

Post away. I’m just sitting here compiling toolpaths for some CNC work in yet another CAM program…

BTW…you never sent me those files, no?