Forreal… I wanna see this thing get done. Do you think we could swap joe jiggs into your spot in the military, then you can finish this thing?

I don’t know jigs, but I’ve noticed he can incite quite a bit of hatred. It’s probably better for him not to be around this:

(click for vid)

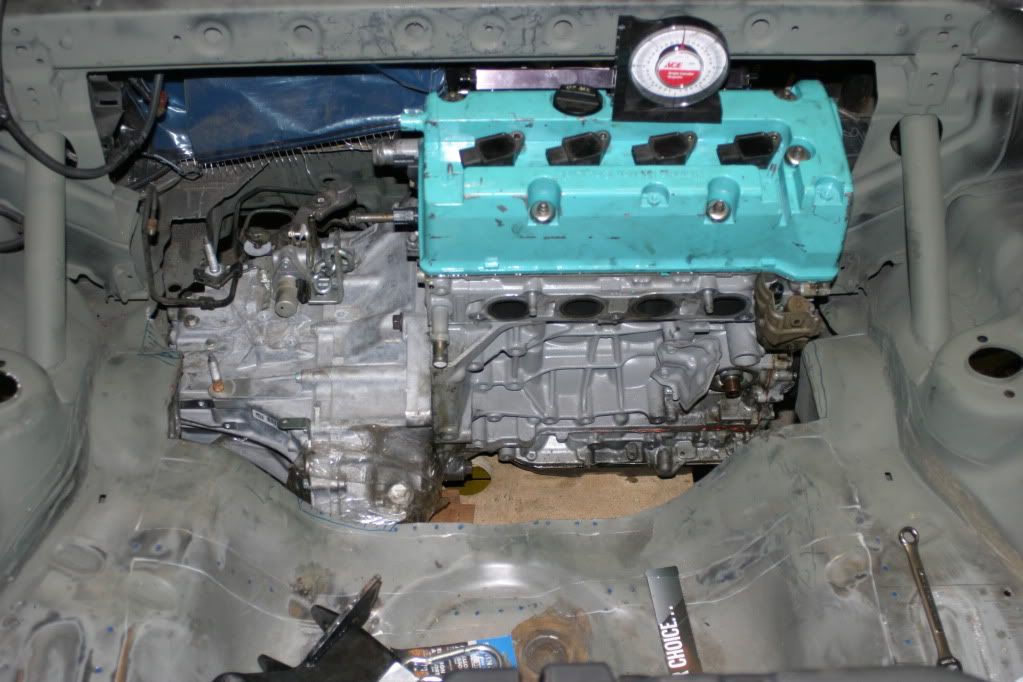

Some more mockup and markup. VERY close to being ready to weld up the frame rails and new engine mounts.

I forgot to mention. That is pretty much the placement of the engine. I bought a motorcycle jack so that I could actually set it down, shim the transmission, and get it located exactly where I want it.

I’m planning some modifications to the jack to make it more useful and easier to pull/install the engine in the future. Modifications will be similar to what this guy did for his LS=Porsche

Made my final cuts to the frame rails and rear firewall and made cardboard templates of my new frame rails. I’m going to put the motor in one more time to check over all the clearances again and then its time to start welding.

Also spent a LOT of time with a wire brush to prep the metal. I have everything I need for this including clecos, weldable primer, POR15, and Eastwood seam sealer.

Let me guess… is that a SAW? But yah, joe jiggs would single handedly ruin the united states military.

That’s correct.

updated below

snapped a picture of you welding when you werent looking.

who needs eyesight? The quality of the weld is all that’s important

Again mocked up the engine to check where my most recent cuts look in relation to the engine mounts. Again, they were intentionally cut about 1/4 of an inch shallow so I could come back and finish it off once I could check it all over again.

Also picked up a plasma cutter for the week, I don’t have any pictures but I’ve been making and refining cardboard templates for the frame rail “inserts” last night I finally got to the point where I was confident enough in the fit of the template to trace it onto the rectangular tube that I bought and cut out the first one. The problem I ran into is that the house I’m renting right now apparently is entirely on only 3 breakers… compressor flips one every few minutes and then the plasma will flip one. I had the entire rest of the house turned off. I was planning on picking up a tig friday but now I’m not so sure that its a good idea. I won’t be able to get a good weld if the wiring in the house sucks so bad that I can’t run this type of equipment without having the breaker flip.

Anyone know if I can use a generator? What kind and can I rent one?

Bigger Breaker just up the breaker its easy. 5min procedure if that…

excited to see the end result

Looks good did you make those motor mounts too?

your house prolly looks like a mad scientists labratory to the nieghbors with all the lights flickering and sparks shooting outta the garage lol.

Damn good thought. I’ve never dealt with them before I’ll have to look into it so I don’t kill myself and minimize risk of burning down this house.

It is pretty funny, between the grinding, cutting, lights, fans, lift, air tools, air compressor… lots of sights and sounds when I’m working.

The mounts were hybrid racing mounts, I thought I was going to have to make some myself but these work perfectly. I’m just going to toss the aluminum trans mount on the mill at work for a little bit more clearance over the subframe.

Most 110/115v single phase plasma cutters will draw around 20amps at the breaker. Make sure the wire in the wall is rated for at least that before attempting to swap in a larger breaker.

gotcha. thanks. This will be a huge help. the house is almost entirely on one 15amp breaker. The entire downstairs goes out when I blow it.

There are more breakers on the panel up to 30amps. If I can just find where that outlet is I’ll be all set.

Your best bet so you don’t go burning shit down is if the panel has an extra slot or two, go ahead and wire in a separate breaker for the cutter. It’s not that hard to do, probably cost you $50-$60 in romex and breakers/outlets/etc…I imagin the main is probably a 200 amp service.

Find what the max draw of the cutter is. if’s it 20amp, wire in a 25amp breaker. house current type cutter and welders typically won’t draw more than 20amps.

I really don’t want to mess with anything in the house, this three photo tour will explain why:

Ah that’s nothing. Far worse has been dealt with in other homes I’ve done wiring in.