Posted it on the spec v forum so i figured id post it here too for shits and giggles since no one else has a boosted spec on here that i know of. i started ordering all the parts and whatnot back in October of '07. the install started the day after xmas in my garage at home with the car up on jackstands. took me about a week going at a moderate pace without rushing anything and doing other stuff here and there so i wasnt working on it all day most of the time. the turbo install was probably the most complicated thing ive done with my car before so i wanted to do everything myself so i knew how to fix anything if something happened.

i had mike tune it over at innovative and justin tapped the pan for me so i

didnt mess that up at all lol.

heres a list of everything i installed including the kit,exhaust gauges,etc.

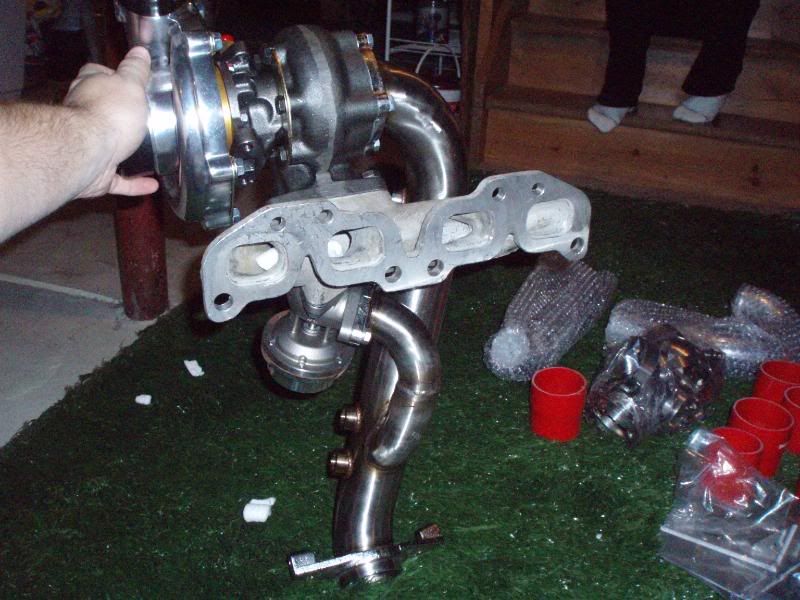

Treadstone kit Parts

- Turbonetics T3/T4, 50 trim T04E compressor wheel, .63 turbine A/R

- Turbonetics Evolution Wastegate

- Treadstone 347 Stainless Steel Cast Turbo Manifold

- Treadstone TR8 Intercooler with brackets

- Treadstone Polished Aluminum Pipe Kit

- Treadstone MAF adapter

- Treadstone Red Silicone and T-bolts Clamp kit

- Treadstone 304 Stainless Steel Downpipe

- Treadstone Stainless Steel Oil Kit

- Tial 50mm Blow Off Valve

- Treadstone Air Filter

- 440cc Fuel injectors with clips

- NGK Spark Plugs

freshly out of the box

Other Parts

-

Prosport Gauges: Boost Gauge, EGT Gauge,Oil Pressure Gauge

-

AEM Uego wideband

-

Greddy Full Auto Timer

-

Golden Eagle Vacuum Manifold

-

Ajusa Multi Layer Steel Headgasket

-

Greddy Emanage Blue

-

VRS Aluminized 3" Inch Exhaust

-

T-Pros 2.75" midpipe

- 14 Washers for the Wheelhop Aid Kit (replaces rubber washer things on crossmember)

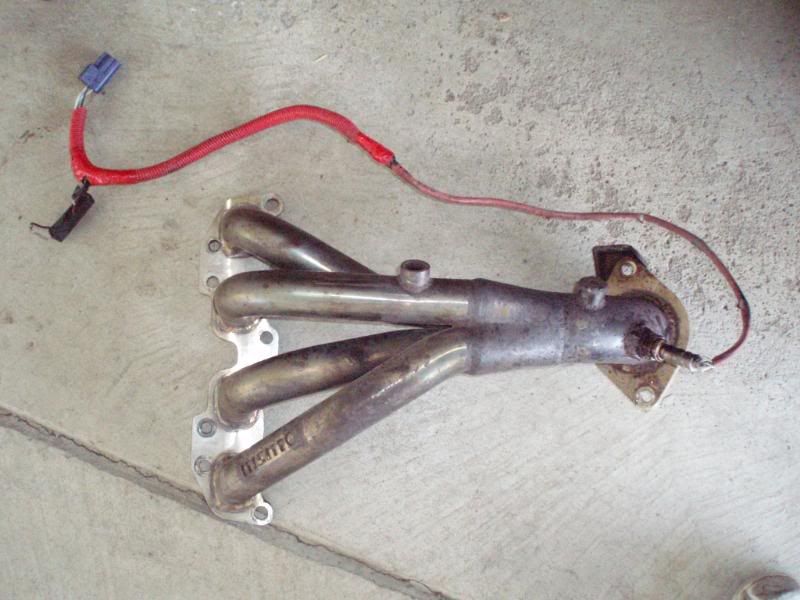

i put on the 3 inch exhasut and the new midpipe a month before hand at the shop so i could do it on a lift rather than on my garage floor which wouldve been a pita since i ended up grinding a few bolts off. heres a few pics

it sounds pretty good. got rid of both cats and the midpipe has one resonator in it so its louder than i wouldve liked but its tolerable

-

took off the front bumper,front wheels,headlights and hood

-

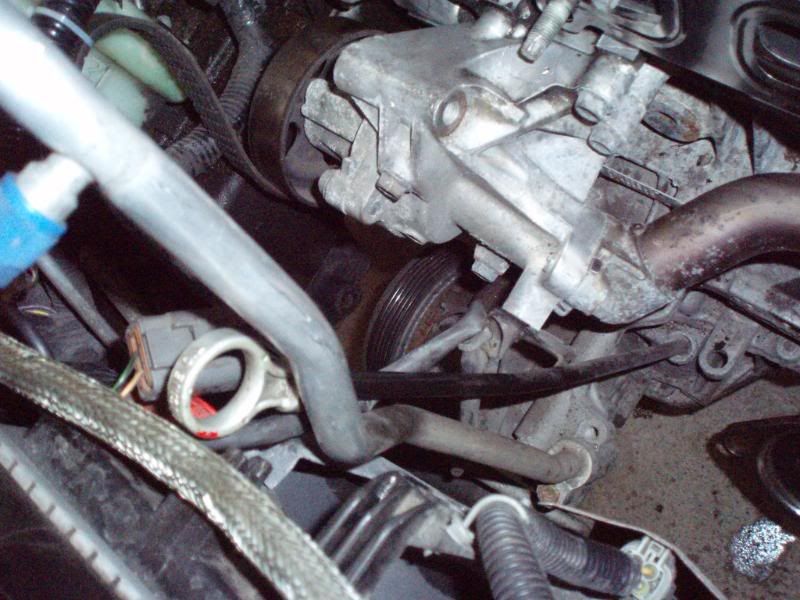

shot of engine bay with all the n/a parts on still

-

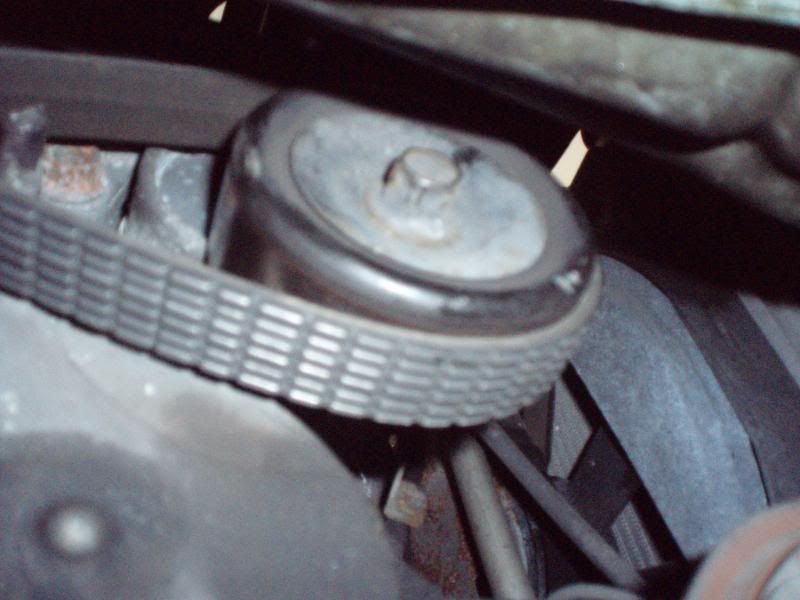

loosened tensoiner and took of belt and alternator

-

took off header and midpipe (o2 sensor was stuck in there pretty good til i heated it up

-

bent oil distick tube and ac line out of the way so the downpipe will clear it

-

test fit the hot parts to see if the oil tube and ac line werent in the way

-

rotated the compressor housing to make sure it clears the fans so the ic pipe will fit and tightened on of the bolts down to hold it in place.

-

took off lower tie bar and crossmember

-

started to take off the 25 or so bolts for the oil pan (lower and upper)

stupid bolts for the dustcover by the flywheel

- finally got the upper pan off

justin tapped the pan for me over at innovative

-

put both oil pans back on and put all the bolts back in

-

started with the oil feed line and routing it the way i wanted. placed in the back of the block where the stock oil pressure sensor is. a “t” was put in to get a good feed rather than use a sandwich adapter or whatever.

------im gonna split it up into different posts since im taking some stuff out that you guys could care less about like all the little instructions. and i have to go to class. ill finish it later today most likely

can’t wait to see it run

can’t wait to see it run