I love how you clamped this down to the table…love it soo much@

Are you going to finish off the manifold with some coating?

I love how you clamped this down to the table…love it soo much@

Are you going to finish off the manifold with some coating?

Going to leave it raw until the winter… then maybe change it up. I wanna make sure it doesn’t leak anywhere before it gets coated

Good thinking, go black chrome please, thanks.

How much per ride and whens your earliest open appointment?

Ok, so… I didn’t want to wait weeks for valve shims, and I also didn’t want to pay 10-22 dollars each for them. I called around to a few vendors in the states and no one had the sizes I needed.

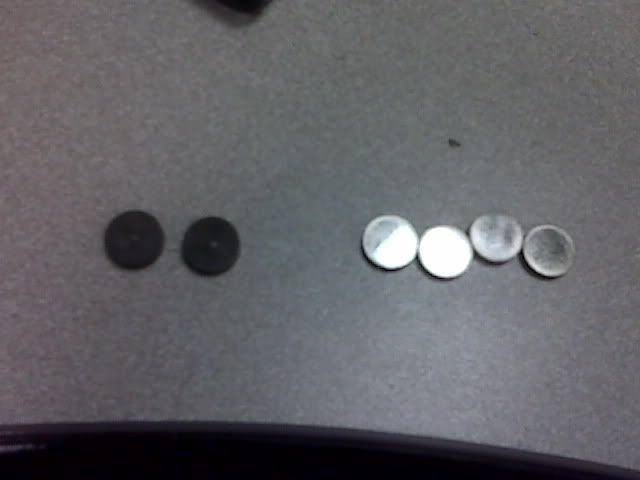

So I made my own (did a few tests on the shims I pulled from the car to determine surface finish, hardness and material):

Started with a 6 feet of 1/2" 52100 bearing steel rod. $15

Using a CNC lathe, turned the OD to 12.3mm

Using the same CNC, chopped the rod into discs of varying thickness, about 40-50 total (no pic)

Sent the discs out to a local heat treating facility to be hardened to 62-65C (pic below, left) $50

Used a surface grinder to take the shims to within .0005" of what I needed. (pic below, right)

Here’s a little video of the surface grinder in action. If you look closely you can see the sparks flying. The table moves left to right then indexes forward and backward. Once it has completed a whole plane, it drops down .0005" I could have incremented in .00025" steps, but that seemed like overkill, since nissan specs call out +/- .001"

you sure have some old ass equipment, or is it just that they don’t let the desk jockeys play with the nice stuff

love reading this thread, glad you switched to a host not blocked at work!

R&D gets all of the hand me down equipment, so yeah, kinda. Our production machine shop is baller.

How do you hold the shims to the bench? I would think they would get moved around…

Magnets

Plus the stuff works, and it is accurate, so who really cares how old it is?

Production is where the nice machines are, but nice machines are purchased to make money not sit around collecting dust like these do sometimes. These machines are retiring slowly lol.

The surface grinder’s table is electromagnetic. You just set em on there and flip a switch and they’re stuck very securely.

I had to make 2 more shims this morning because I must have measured wrong, so I expect to have the cams in and motor together today or tomorrow…

awesome DIY going on here…

thanks!

plenty of copper heat nuts in 8x1.25 in stock

word, thanks.

Took a half day and worked on the top end from 12-11. About half this was already done from a few days ago…

Head on:

Intake manifold on:

Coolant pipe on:

Balance tube and IAC valve on (also a ghetto hose clamp in the middle of a hose trying to relieve a kink):

Kink fixed with prebent tube, waterneck on:

Injectors and oil filter in:

Fuel rail on:

Plenum on:

Cams in, with custom valve shims…

Timing backing plate:

Timing gears and belt installed. All tensioned:

Rocker covers on:

Another shot:

Everything else. It’s not really pink in person, it’s more purple. The camera just doesn’t represent it very well.

Yessssssssss

this is coming out really REALLY badass

lookin good.