"It’s hard to put into words the emotions that a Porsche can evoke in a car enthusiast. The welling deep inside that we get from beholding such an amazing machine. It isn’t lust. It isn’t jealousy. It is a passion for perfection. It is a demand for respect. Porsche, in its own right, has become the pinnacle of design. This is poorb0yw’s (Princeton) interpretation of this pursuit.

Princeton’s ultimate goal was to build a pure drivers car that could be enjoyed occasionally on the street as well as at track events. “You have to understand the only fabrication work I have ever previously done was of the folded paper variety.” He goes on to elaborate, “The 911 line has been my dream car since childhood. I initially wanted to do a complete remake on an earlier 911 but ended up with the 993 instead. My stock 1996 993 Carrera 2 was purchased as a blank slate for me to learn about cars. The car was built while I was finishing up college, which was around a two-year period. The rewiring, weight reduction, interior modification, turbo system design and fabrication were done by myself under Jason’s guidance at his shop.” Every modification was motivated by an obsession for weight reduction and functionality and here’s how.

Exterior body panels and parts for a Porsche are usually steel or aluminum. If you don’t like carbon fiber please don’t read past this point because this article isn’t for you. With the compulsion to lighten the car, Princeton’s choice of parts consists of a GT2 Evo2 front bumper and splitter while custom lightweight fiberglass front fenders and Clubsport widebody fenders flares and rocker panels eat up the rest of a parking spot a normal Porsche would leave behind. While Porsche front hoods are relatively light, a GT-Racing carbon fiber front hood along with a carbon fiber OEM style deck lid were chosen for street duty. When this car is outfitted for track duty a Porsche Motorsport GT2 Evo Carbon boomerang, AIR GT1 carbon fiber rear deck lid and wing with custom aluminum wing uprights are fitted to the car. To close up the sunroof, a custom carbon fiber sunroof plug of course aids to the weight loss obsession. In the front trunk (remember the engine is in the back!) a lightweight Odessey PC680 battery is placed with a custom carbon fiber trunk trim panel as well as a Seine Systems carbon fiber hood prop to hold up, well, the hood and decklid. A Catz HID headlight conversion lights the road for those late night spirited drives. But this diet for weight loss doesn’t stop there. It flows into the interior as well.

Inside the Porsche you will see a Racepak UDX data logging dash and lightened wiring harness followed by more carbon fiber, which includes a carbon fiber Racepak mounting plate. What more could be carbon fiber you ask? Well lets see, how about a custom carbon fiber radio block off plate, RS lightweight door panels and center console package tray followed by a carbon fiber ball shifter, door sill plates, driver pedal boards, and an OMP carbon fiber dead pedal. Even the carpet was exchanged for RS Lightweight Perlon carpet and knee padding in pursuit of weight reduction. Keeping the driver and passenger in place are Sparco 5 Point competition camlock harness systems that strap you into Recaro SPG racing seats. An Autopower 4 point Roll bar along with Speedware blue aluminum seat side brackets and a Brey-Krause seat back brace complete the handling all safety situations. All this weight reduction adds up to approximately 400 pounds. That adds up to more than three hot chicks. Or a couple of fat ones.

Keeping this featherweight on the road requires wheels and tires that are excessive for all but the most extreme cars. These take form as Custom 3-Piece Kinesis Motorsport K28Rs, which have shot peened and gold anodized centers, sized as 18x10” front and 18x11.5” rear. Providing the grip are Michelin Pilot Sport 285/30 up front and 315/30 out back. Getting these massive wheels to point where you want the car to go required a Momo trek steering wheel with a Snap-Off quick release. Keeping the whole steering package precise as possibly are Bilstein Porsche RSR coilovers paired with Eibach race springs. Supplementing the coilovers are The Racers Group front monoball camber plates, upper mounts, spring hats, seats lock rings, with front and rear drop links. The Racers Group front (sized 25mm) and rear (sized 22mm) adjustable sway bars replace the stock Porsche sways. At the speeds this Porsche is capable of, custom brake cooling ducts that attach to the Porsche braking system from a twin turbo are required.

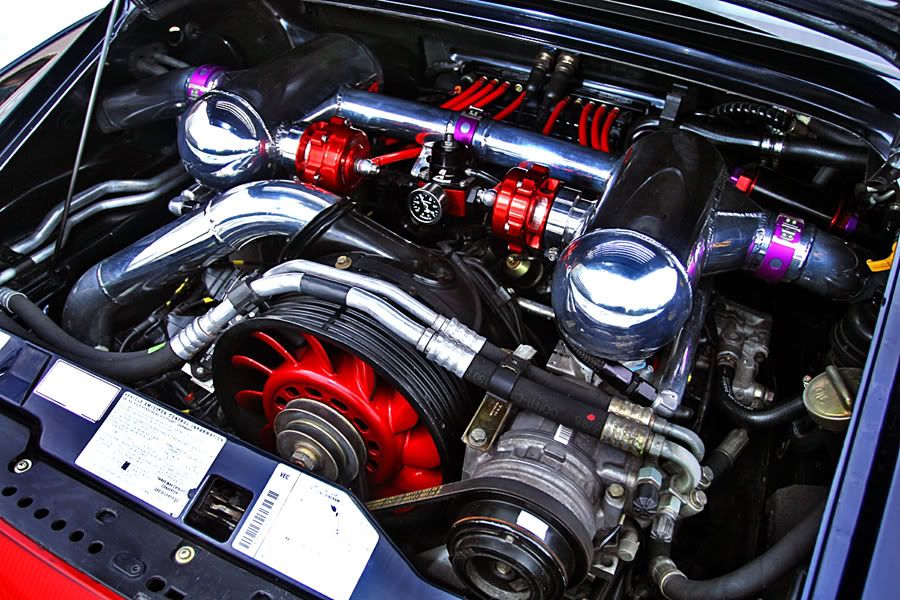

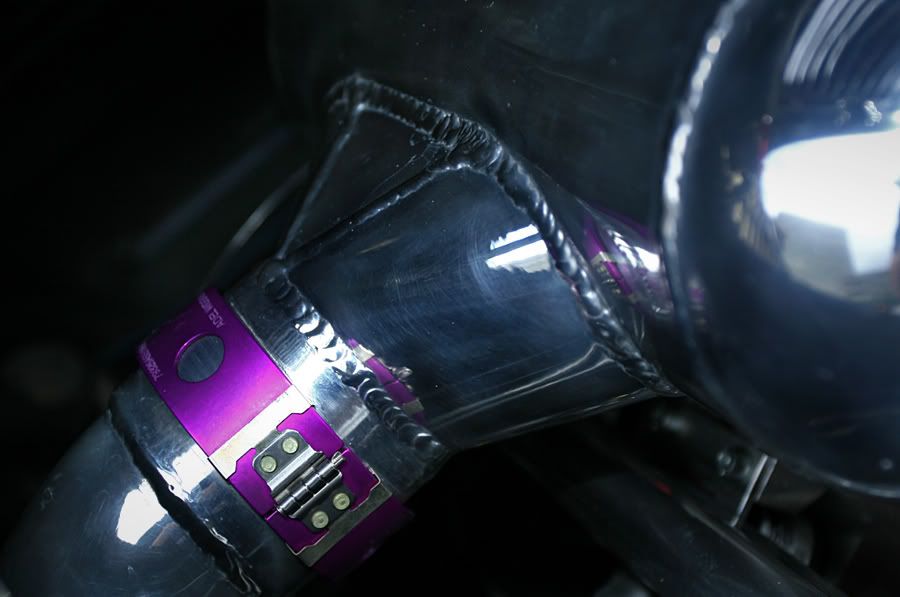

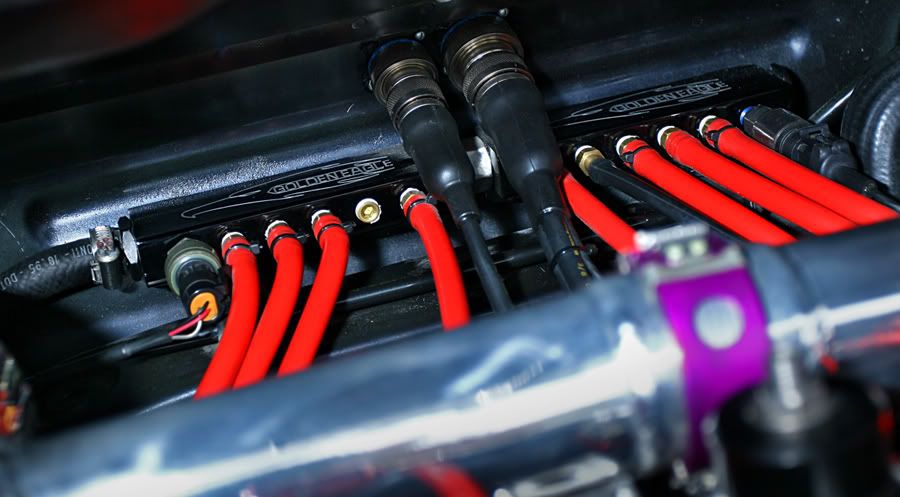

No stone was left unturned in this Porsche’s motor. A custom dual Garrett GT30R ball bearing turbo system, with custom 4-bolt exhaust housing, was designed and fabbed with the rigors of track duty in mind. Dual Tial blow off valves were used along with TWM individual throttle bodies that were modified to retain the stock air conditioning system with a Cartridge prototype lightweight aluminum A/C shroud. Dual Golden Eagle vacuum manifolds were used, since this turbo charged engine requires multiple vacuum sources for items such as fuel pressure regulator, blow-off valve, MAP sensor, boost controller, boost gauge and any other engine components. Ceramic coated equal length headers, up-pipes, down-pipes, wastegate dump tubes and dual Tial 40mm V-band wastegates were used to keep unwanted heat soak away from the engine bay while at the track. Specially ordered from HKS are high flow filters with black filter elements to keep any dirt from even thinking about entering the turbo system. Keeping the air coming out of the turbo’s cool are dual Garrett intercooler cores with custom end tanks. Both of which are force fed air from the custom aluminum air ducting with silicon connectors. Aluminum intake plenums and intercooler tubing were also used in conjunction with Wiggins flexible tubing connectors for the entire turbo system.

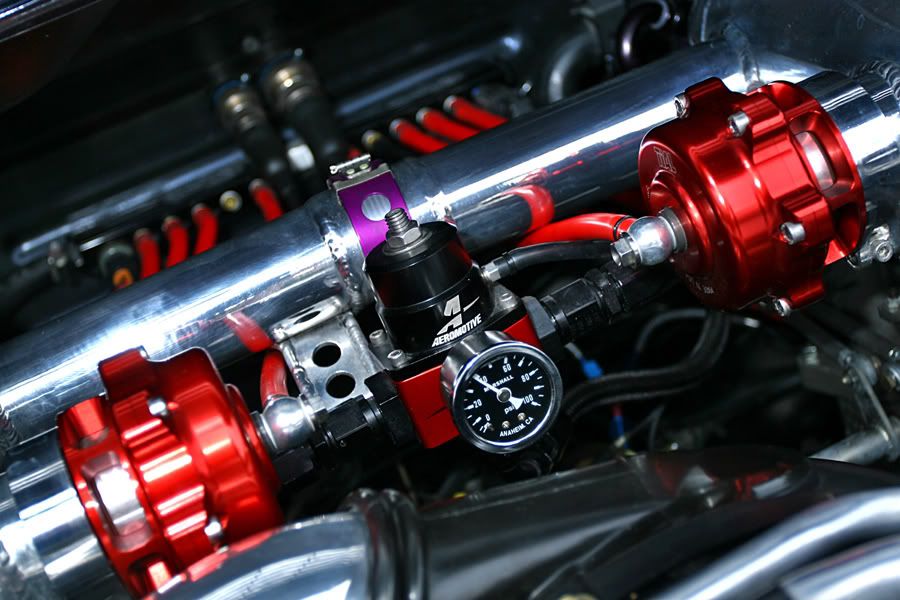

Aluminum was put to use in other ways in the form of a custom aluminum throttle cable adapter, aluminum coolant tanks, and aluminum hard lines for the oil and cooling systems. Since being on a track inundates every part of a car with extreme heat, a Meziere water pump along side a Setrab water cooling core were added to the stock oil cooling system around the turbos. Keeping the oil temperature in check is a billet aluminum oil temperature, pressure, distribution block and Westech oil scavenge pump. Up front is a custom aluminum oil cooler box housing a Setrab 22x7x2” oil cooler with custom Prolite oil lines. Fuel is sucked through an upgraded Bosch fuel pump through Earl’s Ano Tuff fittings and Pro-Lite fuel lines. A Precision fuel filter cleans any unnecessary deposits in the fuel. An Aeromotive fuel pressure regulator along with a Marshall fuel pressure gauge keeps it all in check while the fuel is being sent into the massive custom billet aluminum fuel rail and into the six Precision 1000cc fuel injectors.

Motec M48 ECU was used to tune the engine. A custom Raychem jacketed wiring harness was used with 2 Bosch LSM-11 wideband O2 sensors and 2 Innovate O2 heat sink bungs for tuning the Motec. Keeping the actual motor from moving while taking a corner are Kelly Moss Racing billet aluminum motor mounts. Yes even the transmission was specially modified for the track. Tilton was the company of choice when it came to the modification parts. A Tilton twin disc carbon/carbon road race clutch with a custom machined Porsche Motorsport GT3 RSR lightweight flywheel for lesser downtime between shifts. In addition to the upgraded flywheel and clutch is a Tilton Ultra Low Profile hydraulic release bearing. Custom clutch bleed lines and custom adjustable clutch pedal stops rounds off the drivetrain modification.

What else could be done to complete the car? Could there be even more? How about a fully modified RC car to match. I can’t exactly cover the RC car but maybe we could convince poorb0yw to let us know some details on the RC car when this is published. Princeton would like to personally give credit to Jason (st00pid on Houston-imports.com) “for being my mentor through the entire project. He taught me how to weld, tune, and pretty much everything else I couldn’t learn via a book or the Internet.” Princeton would also like to thank Brad, who was the owner, for putting up with him being at the shop all the time taking up space, Chris (chreeno) for the photography, and Houston-imports.com for the opportunity to be a feature for the front page. Seeing this car live at the track and in action on the street makes it crystal clear that there is no compromise between form and function.

The photography for this photo shoot was done by Chris Reno aka “chreeno” on www.houston-imports.com. If anyone would like more information on photography done by Chris please pm him through the site. I hope we get to collaborate together again. On a personal note I would also like to personally thank Princeton (poorb0yw), Franny (azinwood), Chris (chreeno), and Paul (mobil1) for putting up with me during this feature. "

Pics…

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.