Good job brent keep up the good work.

looks great!

non-jet valve head?

what engine management?

Brian

whats the comp ratio now?

Yeah NJV.This head flows the most and has the least amount of problems.It also has a 3 angle valve job and it ported an polished.Everything in the head is brand new.I switched from hydrolic lifters to mechanical so i could have this big cam in it.

Stock

INT & EXH Duration 264° Seat-To-Seat (Advertised)

INT & EXH Lift .406”-.413”

Lobe Center Separation 109°

Intake lobe is degreed to 107°

Screamin’Banshee:

INT: 292° Seat-To-Seat .454 Lift

EXH: 280° Seat-To-Seat .454 Lift

Lobe Center Separation 111.5°

Power Range 2800 - 6500 +RPM

Intake Lobe Center 107°

They only make 1 bigger cam for this car and it dosent really have any proven results.I havent really heard anything good about it so i went with the one above

The engine managment came with the intake.Its pretty much their own version of megasquirt

The weisco pistons are 8:1

Fucking sweet build, I love the red VC and Blue engine bay. Looks sick.That old intake looked like a shitty setup, looks so much better with MPFI.

cool! have fun.

Brian

Cant wait to hear what kinda #'s this thing put down, hope everything works out as planned :tup:

what do these cars run stock?

looks nice so far!

mid 15’s. Boost controller/dp/dr’s you can run 13’s…Just like any other dsm

Alright so it was time to modify the old exhaust.The header makes the turbo sit farther back.I needed to have a 90 from the turbo so it wouldnt hit my firewall.I went to muffelerman and had them cut a prebent 90 and put a vband flare on it.Excuse my welding.This was my first time and i probably will use heat wrap anyway.

I then cut off the stock flange and some pipe.What you have below is about a 65* angle.

My friend brought over his shit so i could make it happen.

We cut the piece at 12 1/2* so it would make a 90.Protracters are your friend.

It turned out pretty decent.

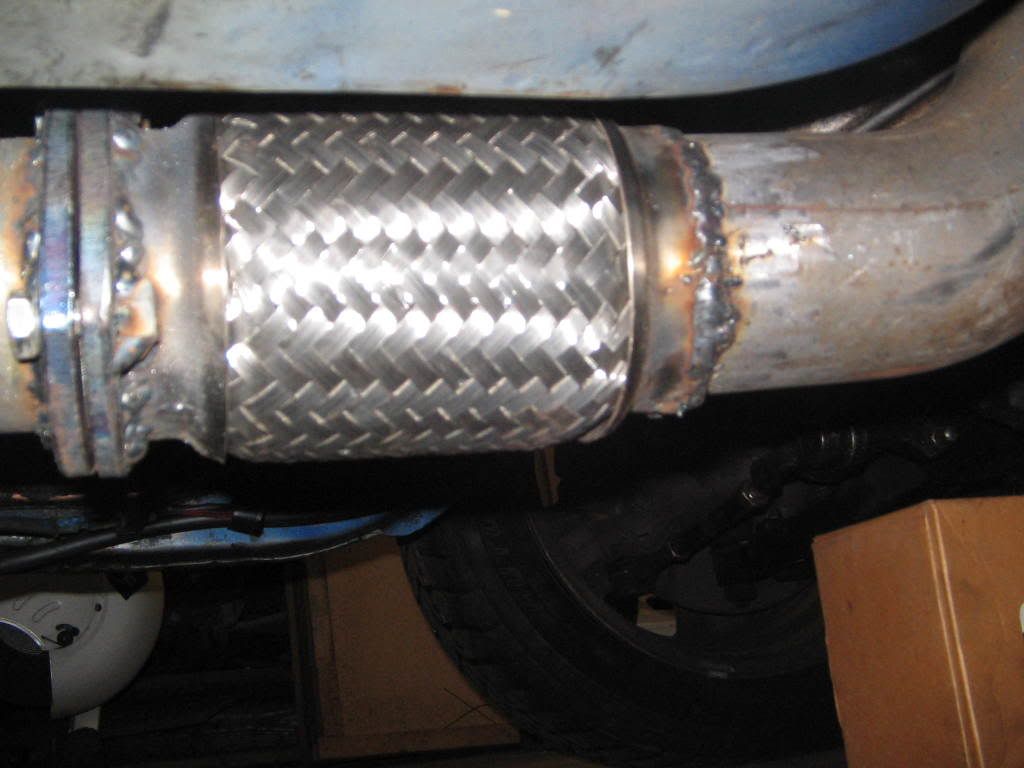

I put in a flex pipe and a 3 bolt flange for removal purposes.I still needed a little more to reach the prebent 90.I just used a coupling for that.

Heres how it sits now.It fits real nice.Im going to run my dumptube later

Underneath the car.I still need a gasket for it.theres a bung on the otherside for my AEM wideband.I welded the nuts in place

The exhaust was only about 3" from the ground before.Now it actually looks right.Nice and tight to the car.

I went to home depot and after some searching around i found these brackets.I figured something like this would be perfect for mounting.I used the stock bolt holes and it seems to be pretty solid.1 underneath 2 on the top.I have some reducing couplers on the way.I mocked up the piping for now.Hopefully thats tomorrow.

Mmmmm…I hate these cars…no srsly. :lol:

just finish yours already.

Hey…it runs! What more do you want?

for you to get more than 1200 miles out of one motor…

4 last summer?

Hey, that engine last summer got like 12,000 before I blew it apart. Gimme a break…these things are touchy. Props to Brent for going MPI. I have wetdreams bout his setup…

updates?

:tup: Where is this now?