I just realized how long it’s been since I was on here, so I figured I would start a build thread. I’ve changed the car a lot in the last few years, and ended up addicted to AutoX

I lowered the car on KYB AGX’s and the Eibach Pro kit, painted the wheels, bought some Falken Azenis for them, switched to Toyo tails, and started getting rid of the black lip.

Installed Eibach front and rear Sway bars

Cleaned up the engine bay

And started AutoXing

This Spring I also picked up HP Tuners

4 Hankook Ventus V12 Evo’s for a set of 18" Nexo PX-5’s I picked up this winter, and two Kumho Ectsa XS’s for my stock wheels to AutoX with.

Oh, and I helped run checkpoints at a local FLR Road Rally this winter (borrowed a friends snow tires, haha)

So it’s nice to be back, and let me know what you think

Front end looks like you have some fitment issues, but it still looks better than most Cavy’s. Not my cup of tea but definitely nicer than what I drive lol. Props to you getting involved and doing some AutoX.

Yeah that’s one of those problems I’ve been messing with for a few years and can’t ever seem to get it right. I’m pretty sure it stems back to a crush beam that was replaced well before I owned it. And thanks

Speaking of which, a couple video’s from this Saturday’s AutoX Test and Tune.

A short compilation of the hairy parts of the day…

https://youtu.be/kzBOQTyewUM

And my fastest run, a 51.9

https://youtu.be/lI2M6y4hCys

I think you have power steering leak

It’s coolant, so nice of GM to make plastic quick connectors that get brittle after about 10 years.

Nice vids. I used to be the proud owner of a 98 turbocharged z24.

I think I saw your build thread on RocLife. Did you fashion for own limited slip diff or something of the sort? I remember thinking it was a really cool build thread…

Car looks good, and seems to hold its own on a solo course pretty well! Maybe I’ll see ya out there if I ever get out to an AutoX this summer

Yup that was me, and thanks to the both of you

I finished machining the rod ends for my composite tie rods this weekend. They are off to be clear zinc plated. The CF came in but I’m still waiting on 2 part foam and resin. The rod ends weighed in at 6.4 ounces each, so they are still under 1 lb a pair

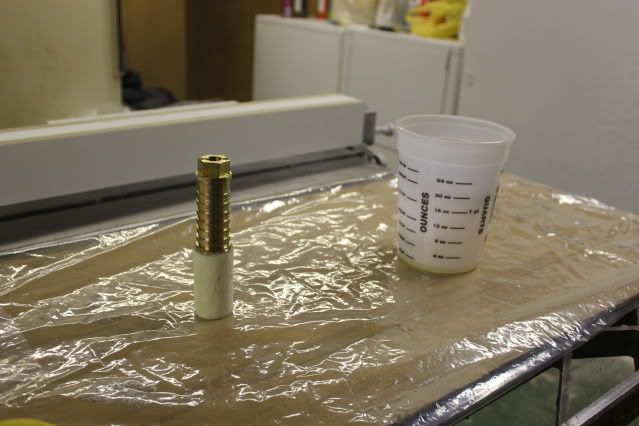

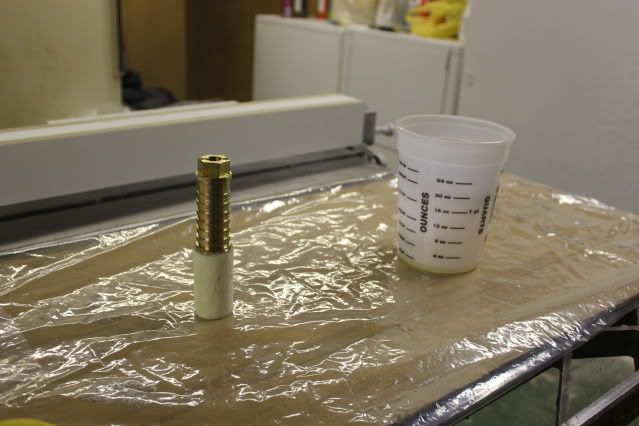

My resin and hardener came in today. I also got the rod ends back from being zinc plated

n/a cavi! i like this alot! awesome build keep up the good work! very nice looking cavi too, and you look uncomfortable in your car lol

:bigtup:

Hahaha, surprisingly it fits me well, there just isn’t any room to spare, lol.

But thanks

After lots of measuring and drawing I figured out I probably could build a Watts link for the rear end of my car, but it was going to take so much added material I couldn’t believe the benefit of the Watts link was going to out do the added weight. Ground clearance and keeping the tie rods straight was also going to be a problem when I lower the car further. So I decided to keep things light and simple and just stick to the triangulated rear trailing arms like JuicedZ4 has.

Anyway, some progress…

I’ve been messing around with my composite tie rods for the last few weeks.

Casting the foam core…

Foam core epoxied to the ends for a test layup…

Pain in the ass unidirectional CF, this allowed me to slide the test piece down into the tube, and pull the uni sleeve onto it. Much easier than the first time I tried it.

All wetted out and with the heat shrink around it

And here it is, I finished the test piece up yesterday.

I finally got the foam core cast and cut to length for the full size rods.

and lastly epoxied the ends on

Once they cure (it takes 15 hours, ugh) I’ll be able to do the full layups on both rods

Lots of progress in the last week.

Some pictures from my first layup…

After everything cured and I pulled off the heat shrink I ended up with this

It just needs a bit of wet sanding and a final coat of epoxy and it will be done.

Today I did a second layup, and actually got some decent pictures throughout the process…

Everything all setup and ready to go…

After wetting out a layer of biaxial and then a layer of uniaxial over top of it…

It’s a pain to get all the fibers lined up

And then after a second layer of biaxial to hold everything together and make it look nice

And finally everything heat shrunk together

Hopefully this one comes out as well as the first, if not better.

Something in my valve train decided to start tapping pretty loud Saturday night, the day before an AutoX… figures… I’m pretty sure it’s a collapsed hydraulic lifter, but we’ll see once I open it up. In the mean time, this is what I’ve been working on the last couple days

https://youtu.be/zrKT6WMFKm4

Cool vid :tup:

Nice work on those tie rods too!

Hah, cool vid (at least it looked cool on my tiny BB screen). Whats the plan with the motor?

Dan

Thanks guys, I just realized I didn’t have a picture of the finished tie rod up yet. I’ll have to do that tonight.

I’m still not sure with the motor, I need to find the problem before I decided what I should do. There are some leaks I’ve been wanting to fix as well, but I’ll probably get carried away with it, haha.

I’ve also been wanting to open my transmission just to have a look at my LSD insert.