Looks great, build’s coming along nicely. I think you live not very far from me, although I’ve yet to see your car driving around.

Thanks, I’m in Clifton Springs, and Henrietta while I’m at School.

I pulled the timing cover, chain, cam towers and head. The valves, pistons, and lifters all look fine, so I’m beginning to think it might be a wrist pin. We’ll see, the oil pan comes off tomorrow. The timing chain and guides also look pretty much brand new, I had the water pump replaced 60k ago so I’m wondering if it was replaced then.

Pictures!

Completely disassembled the bottom end tonight. I didn’t find anything that could cause the tick, so I’m pretty sure it’s a bad lifter again. The engine shows some wear but really its in great shape. The rod bearings are worn as was the oil pump, but the cylinder bores are still in great shape, and after some measuring they are straight and round.

Oil pan off

The oil pump and balance shaft assembly

MASSIVE play in the balance shaft/ oil pump drive chain…

Chain and sprocket off

Oil pump apart, the gear was worn pretty bad

Oil pump drive

It’s a bit hard to see, but that is the tensioner for the balance shaft chain, MASSIVE wear…

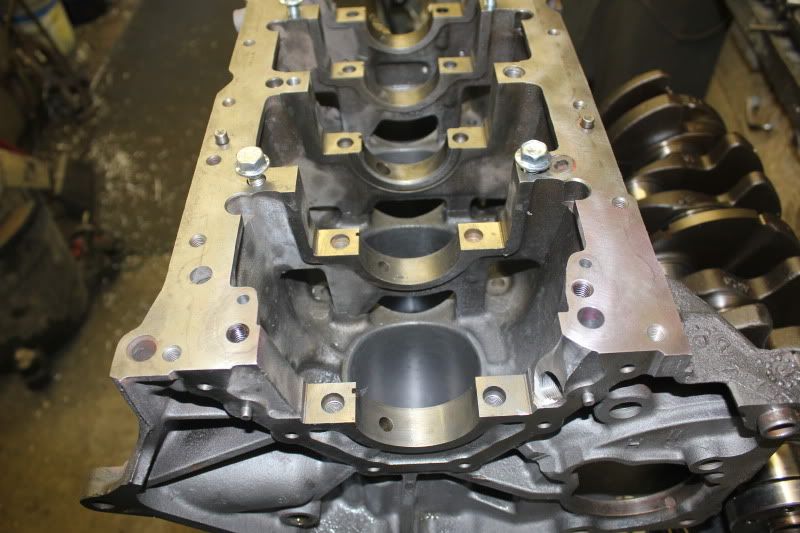

Bottom end

Balance shaft assembly

Pulling the rods

The crank is still in great shape

It needs new crank bearings as well

Cylinder walls are in great shape

Cams look good

Mmm parts

I cleaned up the block and oil pan today, did some more research on the 2.3 oil pump swap and I’m pretty sure I can pull it off. I also ordered the following parts…

Lightweight 35mm lifters

Water Pump

Timing chain tensioner sleeve

Timing chain

Cylinder Head bolts

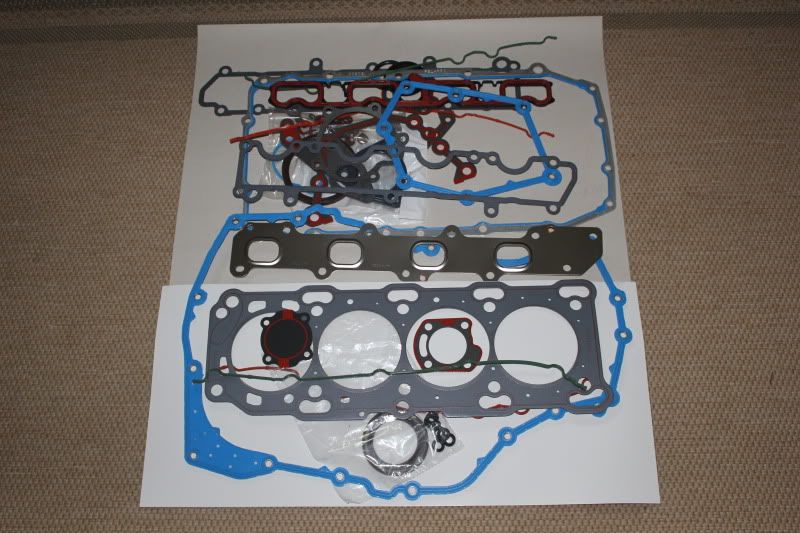

and a Full engine gasket and seal kit

Good way to drop $750… and I haven’t even ordered the parts for the oil pump swap, or new rings, or new bearings… lol

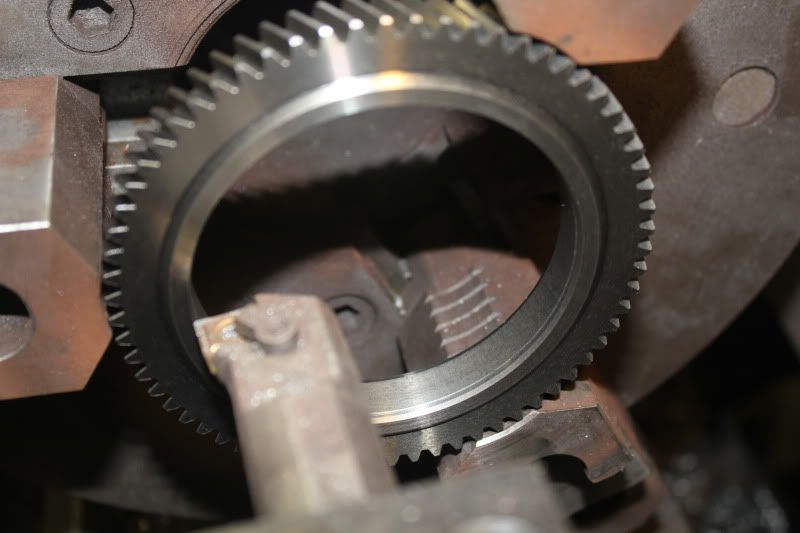

With a little bit of heat and a gear puller I got the sprocket off of the crank, soon to have a gear drive

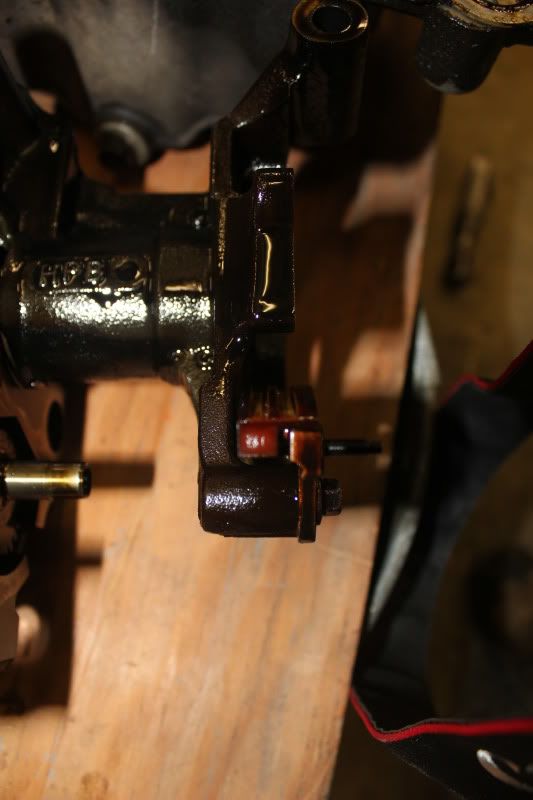

Cleaned up the transmission and started pulling it apart to have a look

Everything looks great, my LSD insert is holding up just fine, a bit of polishing but no galling at all, and all the gears in the diff are great as well

I’ll have to get some pics of the cleaned block tomorrow, I kinda forgot about the camera today.

---------- Post added 06-04-2011 at 12:25 AM ---------- Previous post was 06-03-2011 at 11:45 PM ----------

Some time lapse fun as well

Wow, all that for a tick, you don’t mess around. Nice work on the links.

Looking good. Lets see some final pics of the carbon pieces.

Well it was a pretty loud tick, haha. Once I had it out I decided I should probably install the pile of parts I had for it, and that lead to a fresh engine, lol

I’m glad you reminded me, haha

The second rod still needs some touch up and a final coat for a nice shiny finish. It’ll have to wait until the car is back on the road.

That is really neat. I like it!

Thanks

I machined my W41 cams today, the stock cams have a hex drive for the power steering pump, where the W41 cams have a pulley driven pump, so in the lathe it goes

This is the difference between the two cams, top picture is the W41 cam, bottom is the stock cam

In the lathe

Then boring the hole for the hex insert

And the hex insert

Then I had to drill an oil galley in the cam bearing to allow oil into the power steering hex

And finally pressing the hex insert into the cam

The finished Intake cam

Also I finally got some pics of the crank and pistons

Lastly a slighly worn out oil pump gearset… haha

Hopefully I can start boring the intake cam tower for the 2mm larger lightweight lifters tomorrow.

I dropped my block off to a local engine shop, Grammer Gates, to be hot tanked and honed, which should be done Thursday. He’s also ordering new rods, rings, pistons and wrist pins for me. Almost everything but the stuff for the oil pump swap should be here on Friday. Plan is to run to the junkyard on Friday and try to pick up a used oil pump, oil pickup and windage tray for the swap. I’ll just use the pump for a template to machine the block, and then install the new one when it comes.

Some pictures of carnage while I wait

$900 worth of parts from Napa fits in an awfully small box…

Lots of new parts though,

New water pump, timing tensioner slide and timing chain…

Oil pump drive gear that presses onto the crankshaft, it’s probably been sitting on a shelf for 20 years and it definitely looks like it. Its currently sitting in a bowl of rust remover

Some new transmission bearings, engine assembly lube and a power steering line that I had to cut when I was pulling the engine

Head bolts

A full engine gasket kit

And lastly sixteen 2mm over-sized lifters

However… they decided to change the design of the lifters at some point, which ends up with there being lightweight and heavy versions floating around all with the same part number…

Here you can see the difference, the dish is recessed quite a bit more, and the oiling hole is a bit different, lightweight on the left, heavy on the right

And here you can see the weight difference

Not much, but multiplied 16 times it ends up being 4.48 ounces (over 1/4 lb) less of moving parts.

So I’ll be taking the 12 heavy lifters back to Napa tomorrow, and asking them to order a bunch more that I can pick through. I also ordered the last 16 lifters that Rockauto had, so hopefully I’ll be able to get 16 lightweight lifters out of all that.

I picked up my freshly hot tanked and honed block yesterday. They also decked it .006, yay for more compression! I’ve got some machined left to do on the block, and then it’s time for paint.

I had the same place order new Sealed Power Pistons, wrist pins, rods, and rings for me.

I was waiting to get my block back so I could measure the mains and double check that I don’t need undersized bearings, so I’ll probably order them tomorrow.

Luckly I found an old quad in my local junkyard today as well, so I pulled the oil pump, oil pickup and the mount for the pickup. I forgot my deepwells so I’ll have to go back for the windage tray.

Here you can see the difference in the size of the oil pump. Top is the 2.3 pump that I’ll be swapping to, bottom is the 2.4 oil pump.

And the gears side by side

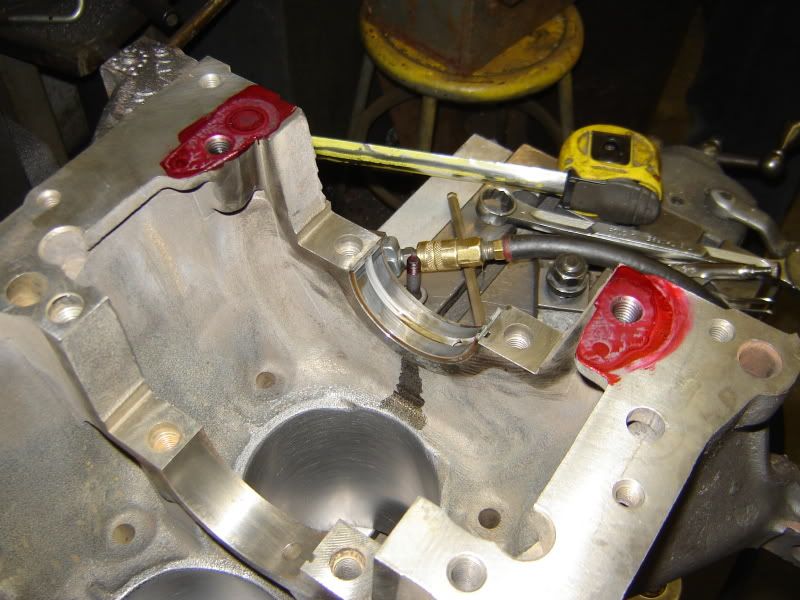

5 quarts of water in the pan to simulate the oil level and mocking up the pump

Then I started hacking at the oil pickup, it doesn’t fit in the oil pan, so you either have to use a different pickup or modify the oil pan. I decided to try modifying the pickup.

I welded it up tonight, the welds look kinda crappy because I suck at welding sheet metal, but it’s sealed up and it now has ~3/4" clearance from the bottom of the oil pan.

I’m going to try to get up at a decent time tomorrow to do some more machining

Where to start… it took us 4 hours to press a damn gear onto my crankshaft… we ended up making a custom gear pusher, so if anyone needs to press anything onto an LD9 crank, I’ll rent it out to you, haha

A little bit of setup, getting the crank clamped down

Then turning a bit of slide fit into the gear so it goes on straight

Cooking some gears for lunch

Then it was a mad dash to press it on, we also froze the crank with CO2

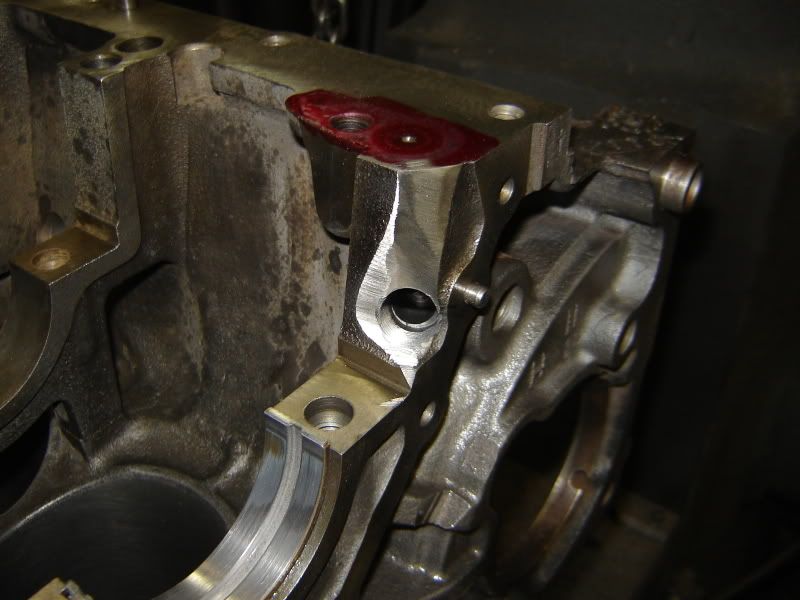

Then came mocking up the oil pump

Done tracing the holes

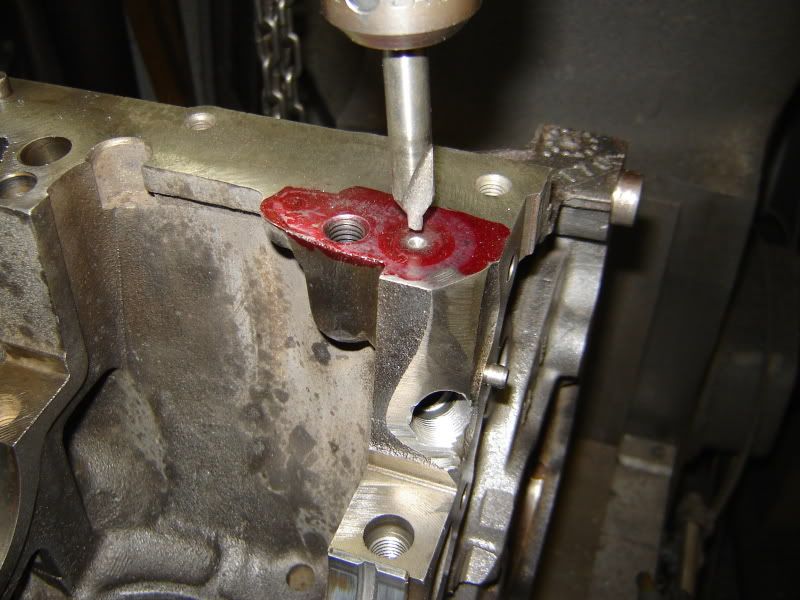

Center punch

And then the scary part…

Tapped for the plug, Few… now I can breathe again… onto the next hole

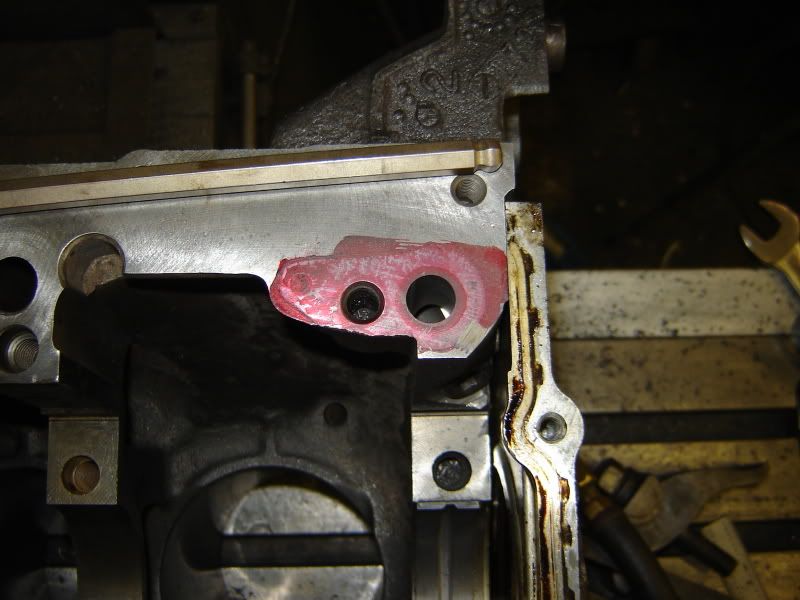

The plug and endplate installed

Now I just need to plug 4 holes in the block, drill and tap two holes for the windage tray, and drill two holes for the oil pump positioning pins. Hopefully I’ll have that done tomorrow, and the block should be ready to go.

I also pulled all the bearings I’m replacing in the transmission, and cleaned everything up for reassembly. Hopefully I can get the transmission back together tomorrow as well.

I pulled my TTR upper engine mount off, since the powder coat was hardly even existent anymore…

Chopped off some useless weight…

Ground it smooth and glass beaded it…

And then a coat of Corroless, I’ll probably do two coats, and I still need to hit the back, but I think it looks a bit cleaner. I was actually toying with the idea of cutting some holes in it for more weight savings, but that might be overkill.

I measured the crank tonight, and found some light scoring in some of the mains. Luckly they were all on the high side of the tolerance. So into the lathe it went. Most of them are at the low side of the tolerance now, but its all still in good shape.

Lastly I disassembled my head tonight, I’m going to drop it off to be decked .010 tomorrow. MMmmm more compression

The valves, keepers, springs and retainers all sorted

I’m just going to stop projecting what I’ll be doing the next day, I never end up doing it, haha

good shit man, this is a pretty intense build up for a cavi, but i like it! :tup:

Thanks, I appreciate it, I’m ready for this thing to be back together…

I took half a day off today to get some parts moving. Stopped at the junkyard to pull a windage tray, dropped my head off at Grammar Gates to have .010 shaved off and a valve job. Then headed up to Rochester to drop my injectors off at New Era to be cleaned and flow tested. Then I got a call a couple hours later saying that two of them were flowing significantly less than the others… Grreeeeeeaaaaaaaat… So now I’m in need of two Ford Brown Top injectors if you have any laying around.

So when I got back I cleaned the windage tray off and mocked it up on the block.

The two tabs in the front needed to be bent down slightly, and I’ll have to slot two holes in the tray but no big deal

My new oil pump and lifters showed up today as well, unfortunately all 16 of the lifters were the wrong lifters, and then I got a call from Napa saying the 16 they ordered for me were also all the wrong lifters… all for a 1/4lb weight savings in the valve train… haha

Mmmmore parts!

New Melling 2.3 oil pump

New main and rod bearings

And an Innovate MTX-L wideband

I had to order a serial to usb adapter for it, so I can edit the gauge parameters with my laptop, but once that shows up from Newegg I’ll be narrowing the AFR range, no need to know I’m at a 7 AFR when 10 is already pig rich, and the same for the high side, haha. The hard part is going to be getting a good connection to the stainless stock narrowband wire to fake the narrowband signal.

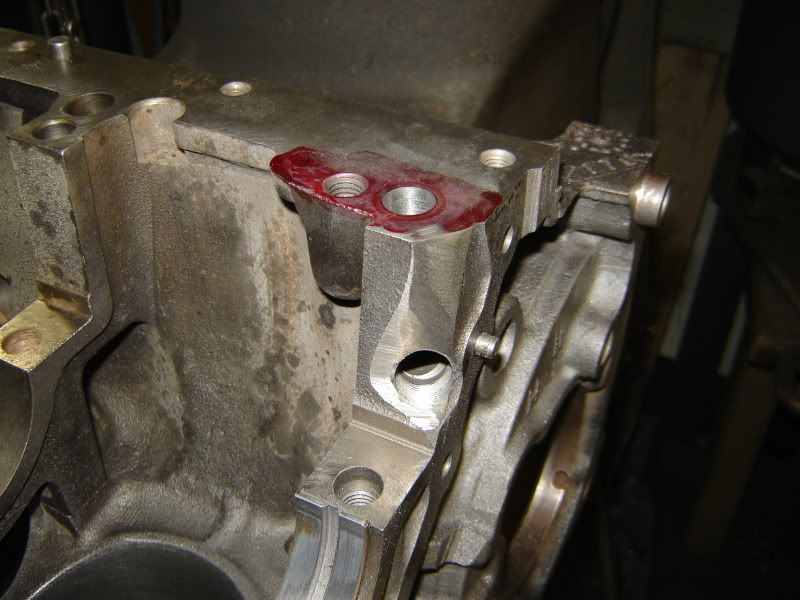

Everything in the block is tapped, I just need to pick up a couple 6mm positioning pins for the oil pump and drill the respecting holes

Windage tray slightly modified to fit

And I also bored my 2.4 intake cam tower out to 35mm for the larger lifters and to clear the bigger cam

According to Napa there are only about 10 more lifters in their warehouses in the US, and no more than 2 at each location. So I just ordered 16 from O’Reilly’s and I’m going to ask Advance to order some for me. I’m going to find these damn lightweight lifters!

Lastly some good news, I found a fellow Quad owner with 4 brown top injectors. $45 shipped and they are on their way

Finished drilling the last two holes in the block for the oil pump swap. Then spent a couple hours cleaning all the oil passages out. Cleaned the block and put a coat of rust preventer on everything. I have a half day at work tomorrow so hopefully I can get the block all finished up tomorrow. 6mm dowel pins and pipe plugs should be here tomorrow as well.

this is really impressive. I’m not a usdm fan at all but all this work is really respectable. keep it up man