That Virago is pretty freakin’ rad.

Here’s that thread on a slightly better looking forum than that garbage.

That Virago is pretty freakin’ rad.

Here’s that thread on a slightly better looking forum than that garbage.

I built a table.

I fucked up the top, because I had intended to place the MDF inside of the outer 2x6 ring, but I didn’t take my time and draw it out like I should have, and I realized halfway through [about when I took the first picture] that I had screwed it all up. Oh well. It’s still a table. It will still hold shit up. …or I could fix it, I guess. Anyway, there’s plenty of space to assemble motors [this and the Fiero’s], and I really like the idea of getting one of these to put on top of one end and level up. Would come in pretty handy for making my own swingarm. I might as well take advantage of the space and shelf up the 2x4 ring at some point. I didn’t have enough MDF for that tonight and it doesn’t fit it the Impreza. Hah.

I’m hoping to get some actual work done on the bike a bit later this week.

let me know what that welding top comes out to delivered…I’ve been keeping an eye on CL for a used assembly/welding table and thats the first one I’ve seen under $200 before shipping…

3/16? I cannot see that staying flat for long…

@Shifty can get you a metal piece to slide on top.

He doesn’t want a flat metal piece, he wants a layout table top. The one he linked would probably be OK for some super basic fab work, but i think 1/2 is the bare minimum for that type of setup.

The link won’t open for me, was just assuming as per the title. I thought Dave can get stuff bent up as well? I’m referring to something like you have on the work bench at your house.

Yea, I was a bit worried about the 3/16". It really does seem kind of thin. What would be your concern for misshaping? Actual warping of the entire surface if not kept level, or cupping in the unsupported areas [12"x12"]? They guarantee flatness to +/-.015", which is probably close enough for the girls I roll with. That 2’x3’ model is just over $200 shipped, with a discount code.

Are there any other [better] options?

Suppose I could grab like three of these and fab up a frame to carry them. Those are 5/8", though aluminum…

…or I could draw something and have it cut locally.

A36, Gr50 or stainless: 1/8, 3/16, 3/8, 1/2, 3/4, 7/8, 1" thick and up, no problem. Any coating: galvanized, anodized or 3-coat paint…no problem.

I can even laser, form & weld if needed.

fixture table group buy? LOL

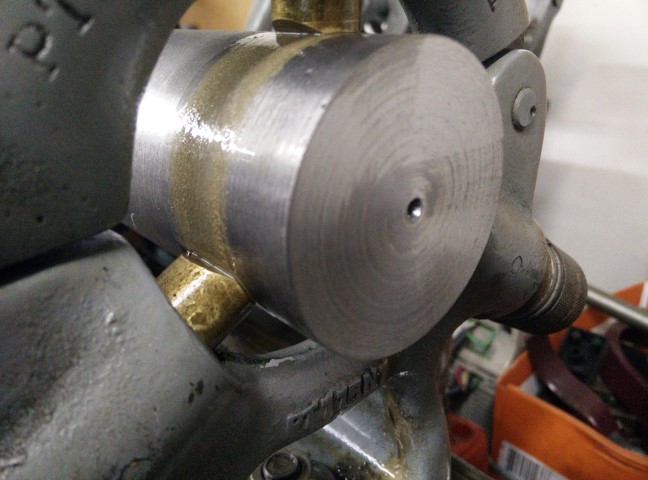

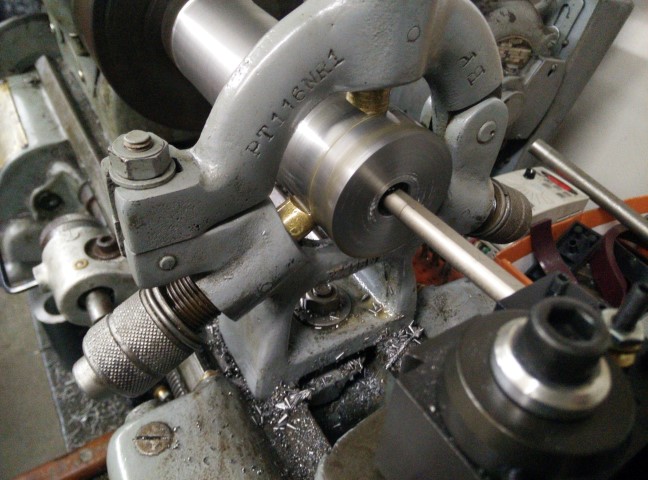

Worked on this a bit today. Started on the pivot housing before I realized that both of my sets of calipers are on my desk at work. I need buy some more tooling anyway, like a 3/4" boring bar/holder and an AXA toolpost. This 0XA one from the Dalton is a bit small.

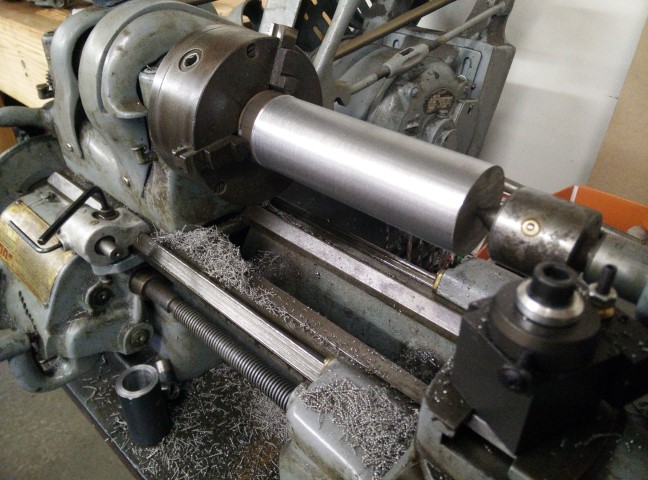

Anyway, I started with a ~7" piece of 2-3/16" 1018 [I think].

Then I chucked it up, center drilled, threw the live center in and turned it.

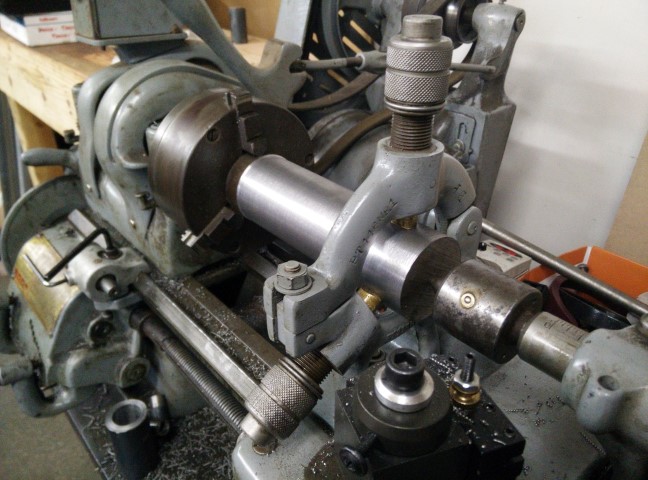

Then I broke out the steady rest to continue machining operations.

Faced it first.

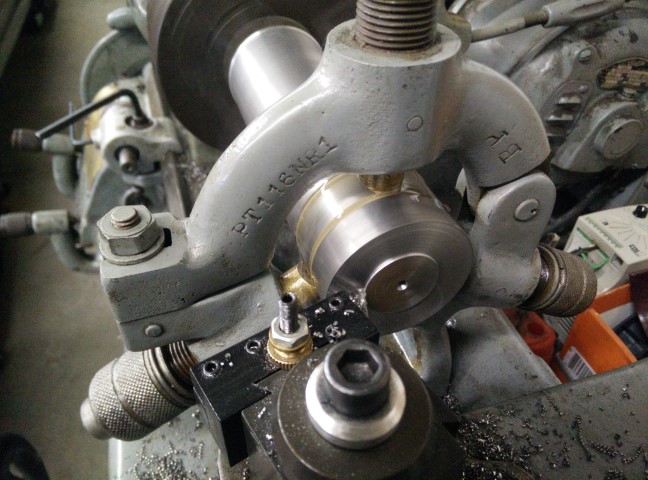

Drilled it, which I didn’t photograph, and then started boring.

…and that’s where I left off, because now I need measuring tools. Hopefully I’ll get some more free time to continue, after I get some more tooling in.

So, it only took four months. But all of my Cognito stuff is here.

I’m content. Not elated. Just content. He took forever and had just about zero communication. Kept feeding me BS when I had to beg for a status update. Plus, look at this nonsense. The fuck is this all about? Looks like a dragging tool. Does somebody not know how to program a CNC?

There’s about ten of those dicked-up spoke holes throughout both hubs. Fortunately, they’re on the inside of the hubs and shouldn’t be super noticeable, but I also shouldn’t have to deal with that after dropping two grand and waiting a third of a year. What a joke.

It might be another few months before I touch this again. I’m almost done with the Fiero, but then I’m moving to my new shop in July. I just need to fab up my swingarm and build those wheels and I can have a roller.

there’s usually a few blemished on cognito’s stuff. I’m not sure what it’s all about, but I know he’s got a 16 or 17yr old kid as a helper. is that his XS650 disc rear conversion hub? I ask because the xs650 has buffers on the trans to act as the cush drive allowing the rear hub to be solid like that…I know about nothing regarding triumphs, but if it’s not similar inside you may beat the piss out of some parts by not having a cush drive.

those hubs would be awesome vapor blasted and cleared

Hah. Damn. Well, there’s a lesson learned. Just a bit disappointing to see when you’ve spent a bunch and waited forever. I mean, like I said; I’m content with the parts and they’ll do just fine, I’m just not very happy with the timeframe and communication. If he had been up front about the timeframe and voluntarily provided truthful updates without being harassed, I’d be stoked.

Yea, that’s his XS650 rear disc hub. Came with the floating caliper mount for a Brembo P32/34 and the necessary link, so that’s pretty nice. The cush drive in the Triumph is built into the clutch inside of the primary, not the hub itself. I bought all new rubbers for that too, of course. Hah. I’m guessing that’s how Yamaha does it?

I’m up in the air on finish. I’ve got the black rims and I’m thinking I’m going to powdercoat the spokes black to match and the nipples the same color as the tank. I dig the metallic burgundy/maroon that’s on there now, and I found a powdercoat that’s pretty close.

I’m leaning toward anodizing the hubs gold to match the eventual Behringer components that’ll go on there, but I’m not fully sold. I’m definitely doing vapor blasted engine cases and cylinder head, so the hubs would match that as well. I don’t think they’d look ‘out of place’ in either instance, just not sure exactly what would be best.

yup that’s how yamaha does it so this setup should be perfect for you. Yeah, IMO cognito stuff is a bit overpriced and he’s really the only guy doing it in quantity and standardized like he is…so of course that means high demand. I think he initially had just done CAD modeling and was having batches made 10 at a time in china until he could afford equipment…then bought equipment and quality got better, but then lead times increased, and as demand grew I bet he started having batches made in china again after he does his prototyping in-house.

black spokes sounds good…the tank color would be sweet as the nipples but I personally find bright golds to be too loud but to each his own. I love when a bike is overall understated to the point where it just makes you look harder at it to realize the thought and design that went into everything. To me that makes for a bike that is truly a build rather than a bunch of parts thrown at a pair of wheels.

Aah, so you know quite a bit of the history of Cognito. Hah. That does help put things into perspective a bit, though. I’m definitely pleased with the parts, I just think he needs to be up front about his lead time and be a little bit better about updating and communicating. That’s all. No hard feelings, I’m just a bit more apprehensive about it now.

That’s mainly what I was worried about with the gold. I don’t want it to be ‘too much’. I think the wheels would look good with the black rims and spokes, tank color nipples and vapor blasted hubs. The hubs are a bit large to be such a bright color. The vast majority of engine parts are going to get vapor blasted for sure, so they’ll match nicely. I’m thinking about doing the rocker boxes gold and not much else. Probably the Beringer levers in gold, but I might go with black calipers in that instance. Like you said, I don’t really want it to be super obnoxious.

I dig this fella, minus the gold rotors and possibly calipers. I want some gold on there, but I don’t want it to overwhelm. Probably just the rocker boxes and levers, really.

The Beringer gold isn’t super bright fortunately. It’s tough to get a good picture when I’m surrounded fluorescent lights, but it’s fairly subdued.

that looks like an expensive sportster :eek3:

No gold rocker boxes!!!

Alright, alright. Hah.

Guess I’m the only one that likes gold. Fuck. The levers, though. THERE HAS TO BE GOLD SOMEWHERE. Part of the theme.

Burgundy, black, gold. It’ll be okay. I promise.