The solenoid, controlled by a toggle switch, will decide if the cutout sees vacuum or not. That part is easy. The harder part is actually having vacuum available to the solenoid. Under WOT vacuum goes away, so unless you have a vacuum check valve installed the vacuum will go away and cutout will close. Luckily OEMs have been using vacuum to power things forever so we have a reliable inexpensive solution available off the shelf.

So let’s say you’re done tooling around with the valves open and want to shut them because your ears are bleeding, you remove power from the solenoid (again via toggle switch), but the valves stay open, because the check valve is still holding the existing vacuum to the valves. This is where I am on the fence, I could install a momentary pushbutton bleeder valve; either way that portion of the lines needs to be bled of vaccum in order for the valves to shut.

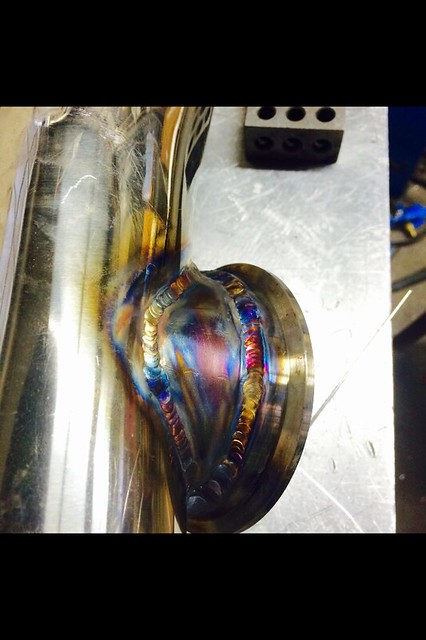

Spring pressure isn’t adjustable without some fooling around, they spot TIG’d the ends of the butterfly shaft so you can’t easily remove the guts