I actually did a refurb on the C6Z lower box when I bought it used, before even installing it in the car for the first time. It needed a thorough cleaning and lubrication, and that did help the general smoothness of the action, but didn’t do anything for the sloppiness.

Here is my train of thought and plan of attack:

The plastic bushings that hold the “yoke” shaft have a 1/16" of slop in them which translates to play in the shift knob when in neutral, or any gear really. They will be replaced with either delrin or bronze bushings that will provide a much more solid “hold” on the shaft.

The C6 Upper box looked to be fine. I found that the black “cup” that rides in the lower “receiver” has no slop and moves very freely.

With the entire drivetrain removed from the car (minus engine), the shift linkage (with no shifter attached) still does not spring back from 5-6 to center. This rules out the shifter as causing my centering issue, although the shifter still contributes to the slop.

I bolted the shifter assembly back onto the torque tube to visualize what the shift linkage was doing, and chase down the slop. This video shows the bushing wear in the lower box. The left to right wiggling of the shift knob/lever at the end of the video has no effect on movement of components in the trans - it’s all slop in the joint at the rear bellhousing! Any similar front/rear movement of the shift knob/lever has equal slop that is a result of the worn bushings inside the lower box.

There is also lots of play evident in the joint assembly right before the shift linkage enters the transmission. It looks to be held together with roll pins, I have not yet disassembled that area.

Of course I COULD purchase a (relatively) expensive aftermarket shifter such as MGW, Hinson, Kirban that has internal centering springs, but I feel that they are somewhat of a band aid to the pre-existing condition inside the transmission. They also tend to be very stiff and the throw is excessively short, which makes the effort go way up. I drive my car 99% on the street with a couple track days a year so an easy, low effort throw is important.

So the final list of suspects, working towards the back of the car:

C6 Lower box mount bushings (that mount the box to the torque tube) - non issue. These are solid on my C6Z shifter. No movement.

C6 Lower box shaft bushings - cause shifter sloppiness. Plan to install new bronze bushings custom sized to my yoke, press fit into box. Not too bad of a job, will require some machining.

T56 Shift linkage to trans - cause shifter sloppiness. Need to investigate, there looks to be a brass bushing inside a mini u-joint that is worn.

C5 T56 internal centering spring - causes shifter not to snap back to neutral from the 5-6 gate (in my case). Again, an aftermarket shifter might help, but I want to get to the root cause. I initially thought this might be caused by the fore-aft detent ball that rides on top of the shift gate (NOT the detent ball that is altered by the anti-venom mod)

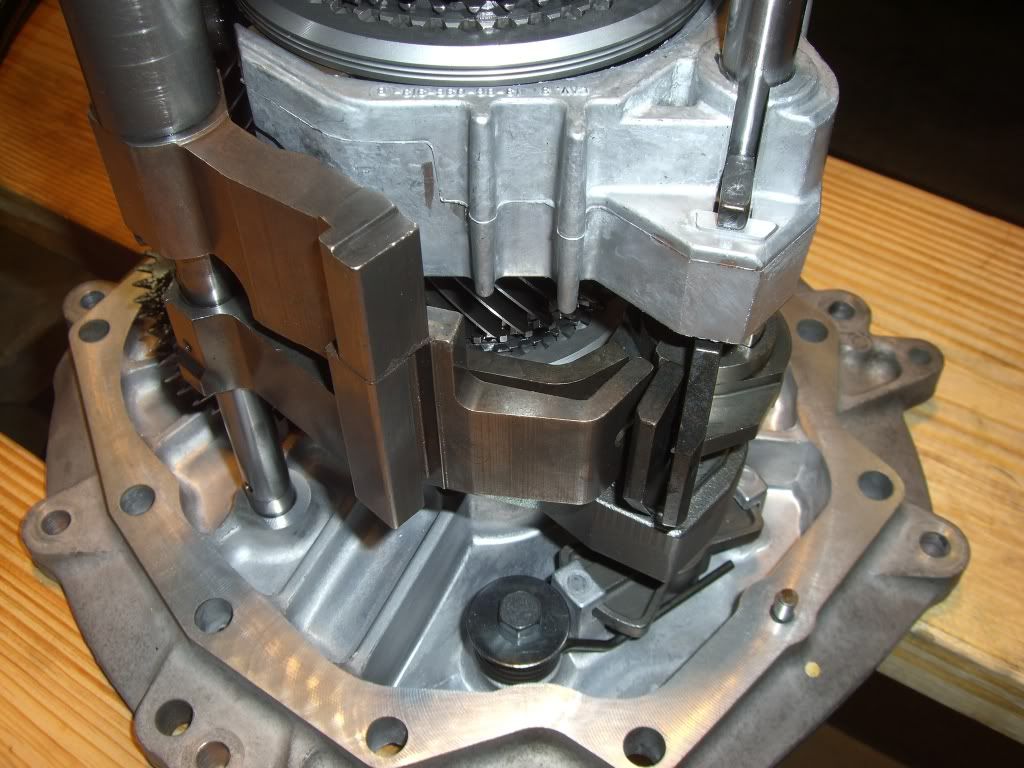

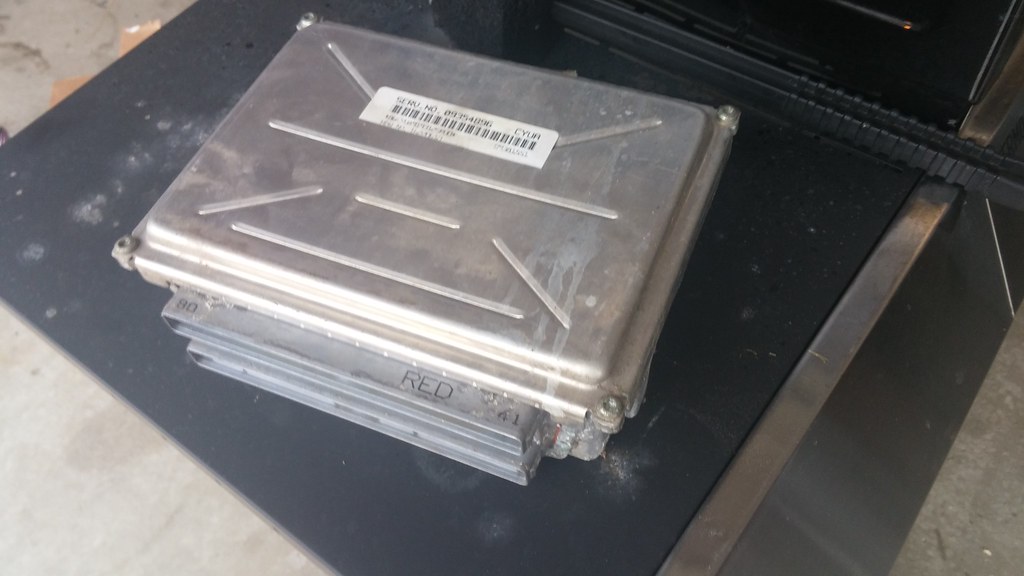

So I mounted up my T56 on the worktable.

0125171925 by Norbert Ogiba, on Flickr

0125171925 by Norbert Ogiba, on Flickr

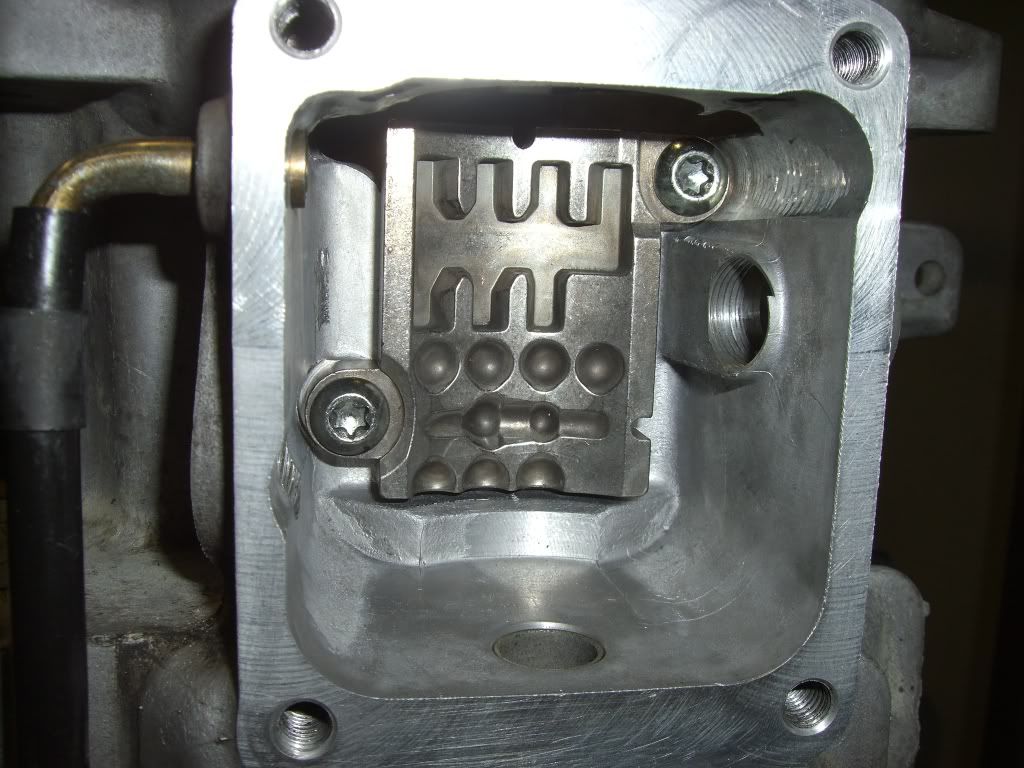

After pulling the rear tail housing case I visually verified that the shift detent ball wasn’t binding up. This is not my picture, just an example of the guide plate that the lower detent ball rides in. I can’t get the shift rail block off yet to verify if the ball is physically free, but that will come later.

According to Bill Curlee: "There is a U shaped spring on the bottom plate that returns the shifter back to the center: " Through the process of elimination, this must be what is causing my shifter not to return back to center.

Tailhousing off.

0125171930 by Norbert Ogiba, on Flickr

0125171930 by Norbert Ogiba, on Flickr

I don’t know if someone has gone through this trans in its life, but the buildup on the magnets didn’t look TOO bad for 115k. I will be removing and cleaning these prior to reassembly. For what it’s worth, I did replace the trans fluid with Dexron III ATF 1 year and 10K miles ago, and it looked brand new while draining.

That’s where I left off for the night, my snap ring pliers were not big enough to handle the rings on the reverse shaft. More to come tonight.

1003162108 by Norbert Ogiba, on Flickr

1003162108 by Norbert Ogiba, on Flickr 1004161855 by Norbert Ogiba, on Flickr

1004161855 by Norbert Ogiba, on Flickr received_10103371545198348 by Norbert Ogiba, on Flickr

received_10103371545198348 by Norbert Ogiba, on Flickr 0923161626 by Norbert Ogiba, on Flickr

0923161626 by Norbert Ogiba, on Flickr 0925161846 by Norbert Ogiba, on Flickr

0925161846 by Norbert Ogiba, on Flickr 1009161148 by Norbert Ogiba, on Flickr

1009161148 by Norbert Ogiba, on Flickr 1009161149 by Norbert Ogiba, on Flickr

1009161149 by Norbert Ogiba, on Flickr