ugh, love me some T Swift

lol

lol x2

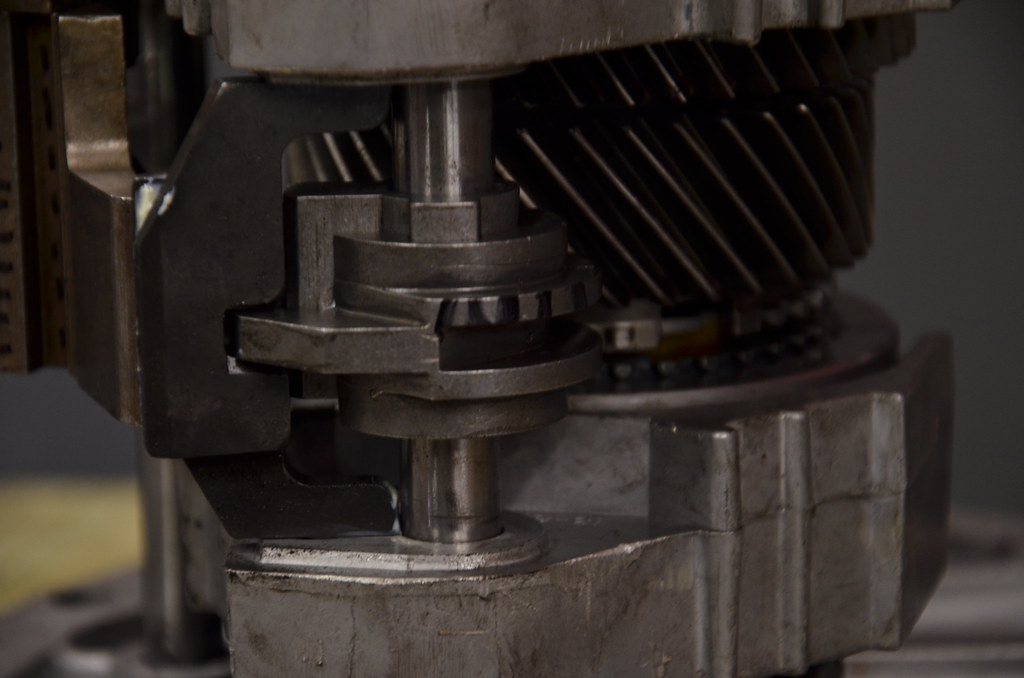

Good news - I was able to pull off the 5-6 driven gear without much difficulty after making up some 3 jaw puller extensions

Not my pic, just an example

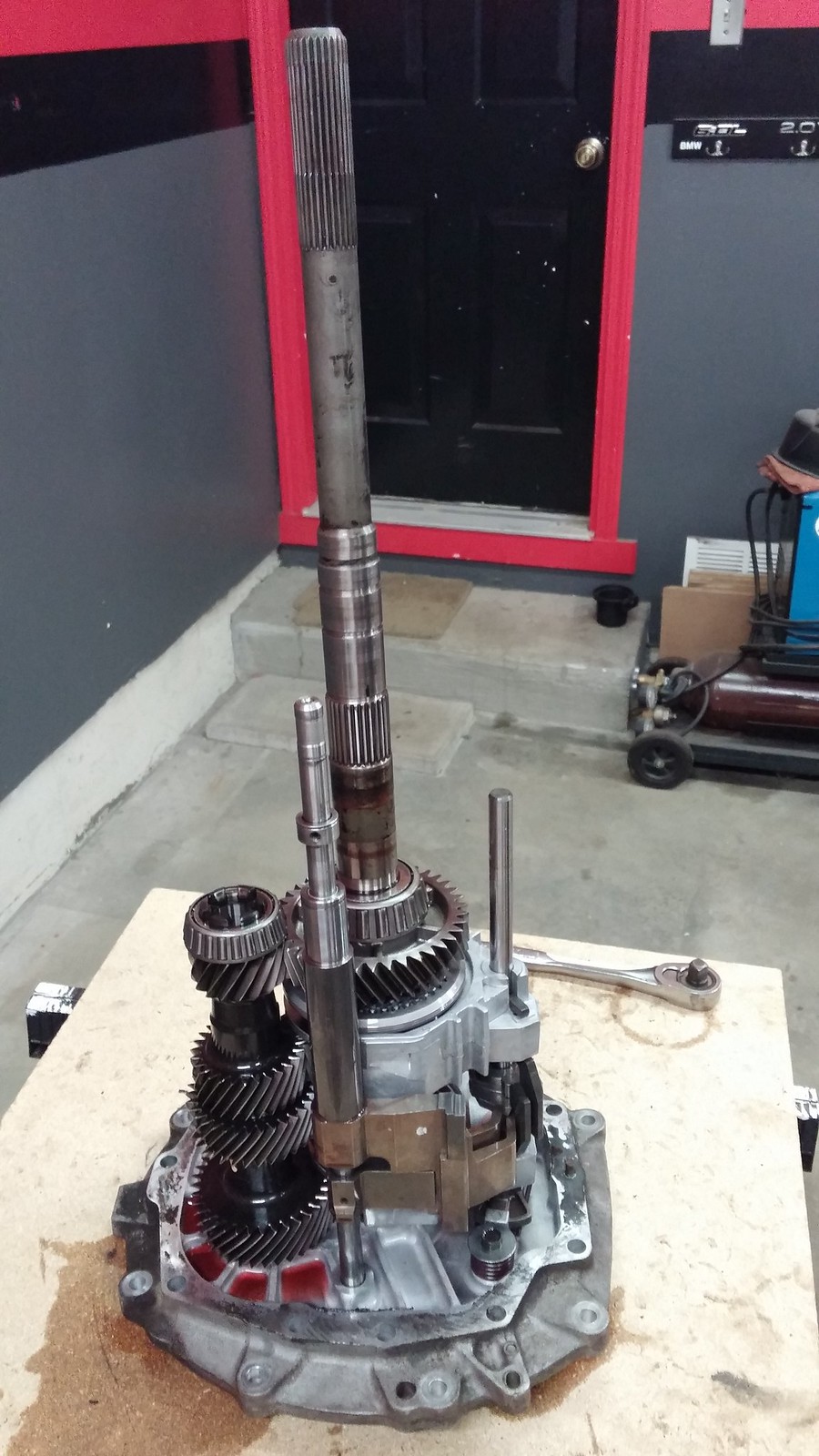

Main case nearly empty of parts (all 5-6 and reverse stuff gone)

Everything laid out in order of disassembly

The bad news is that both the 5-6 and reverse shift fork pads showed issues of cracking. Probably to be expected after 115K miles. I will be replacing them for all gears/forks with billet bronze units.

Magnets will need some cleanup but no chunks of anything on them, just that metallic paste

Hoping to have the main case off the front plate this week so I can finally get to the spring that made me take this whole thing apart in the first place.

Got some work in last night.

Main case off

0131171903 by Norbert Ogiba, on Flickr

0131171903 by Norbert Ogiba, on Flickr

And it’s remarkably light

0131171903b by Norbert Ogiba, on Flickr

0131171903b by Norbert Ogiba, on Flickr

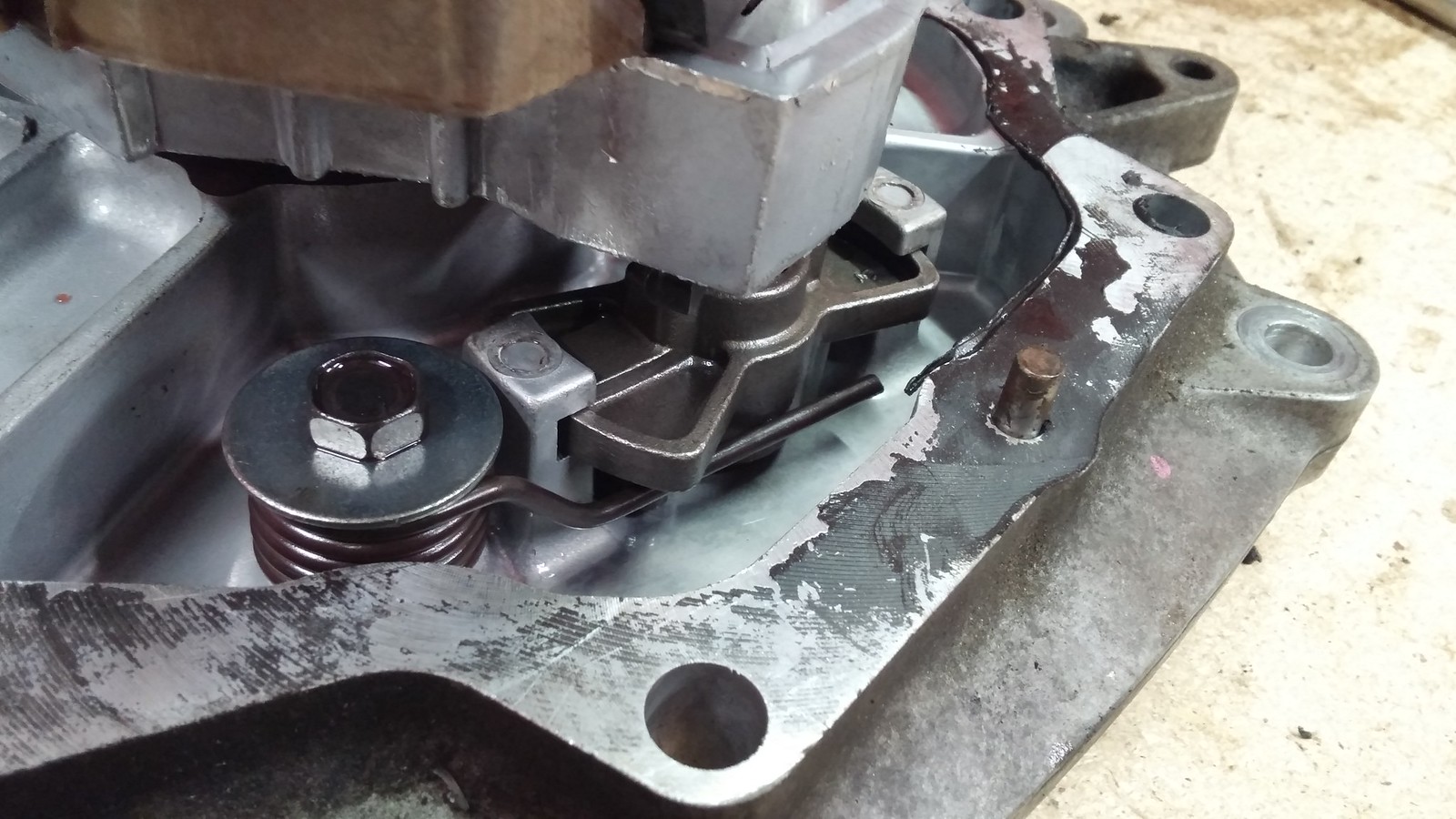

The torsion spring I’ve been trying to get at.

0131171903a by Norbert Ogiba, on Flickr

0131171903a by Norbert Ogiba, on Flickr

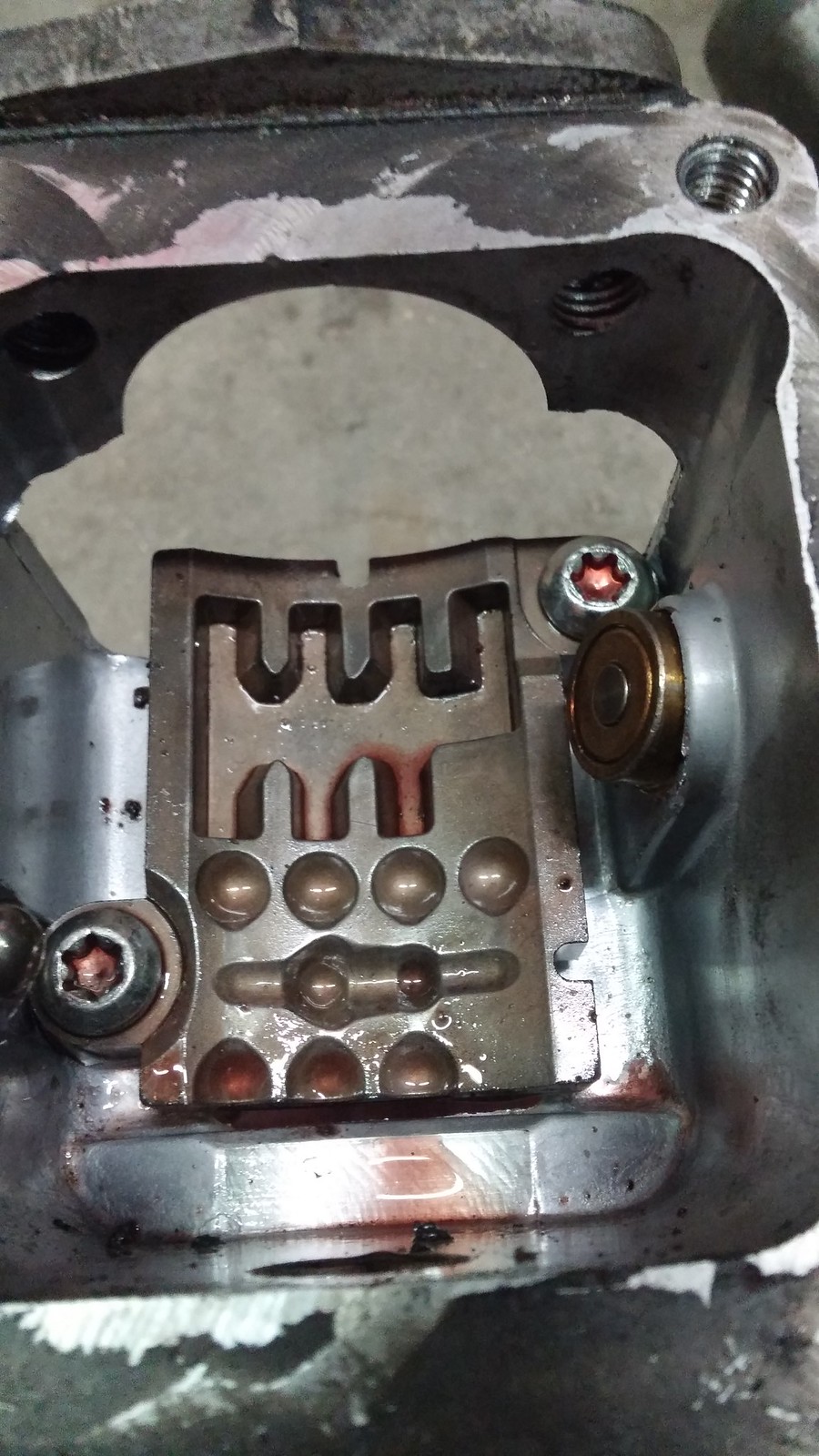

Shift guide plate was in nice shape, so was the detent ball that rides in it

0131171905 by Norbert Ogiba, on Flickr

0131171905 by Norbert Ogiba, on Flickr

Mainshaft off, parts pile grows

0131172025 by Norbert Ogiba, on Flickr

0131172025 by Norbert Ogiba, on Flickr

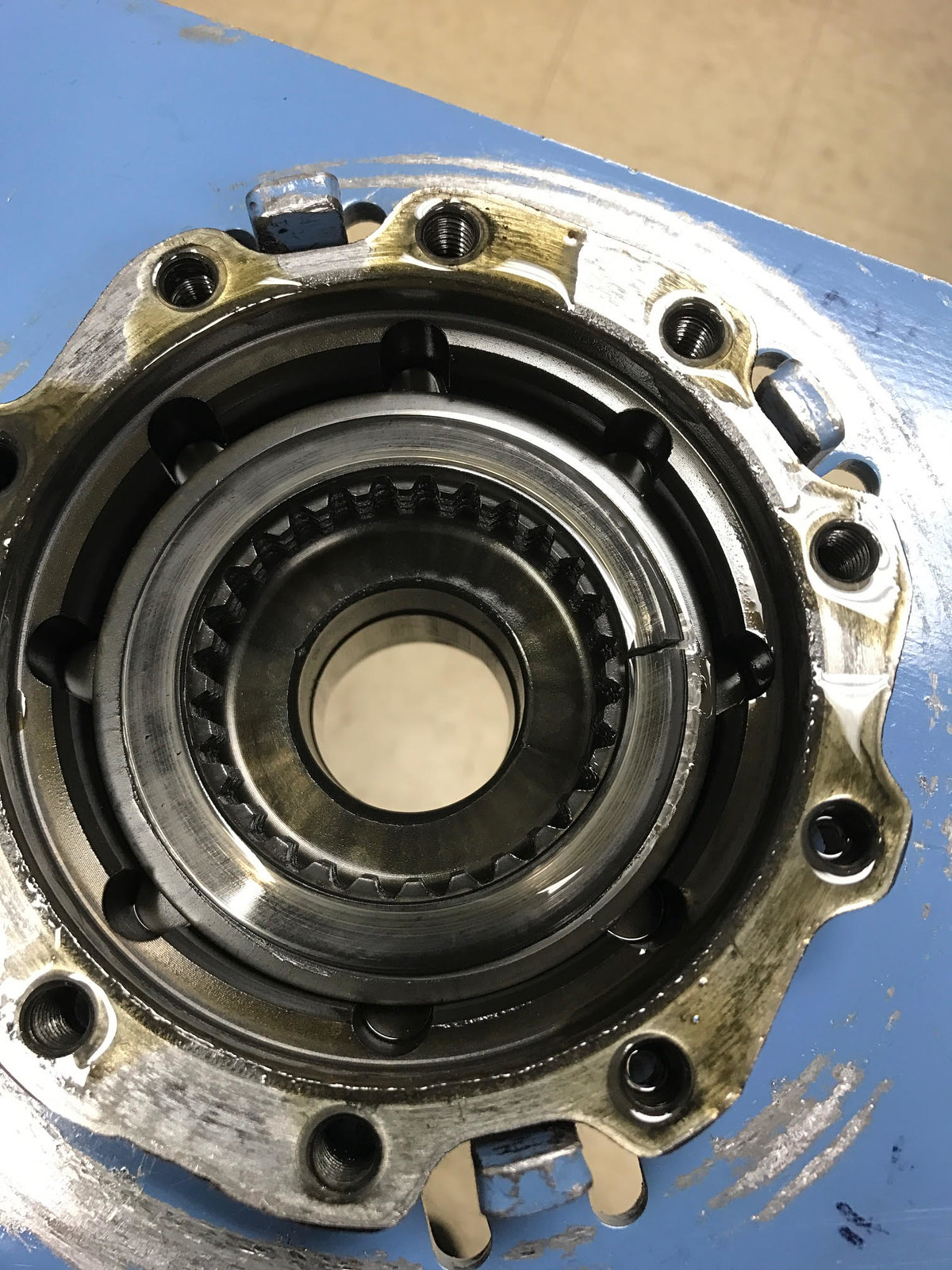

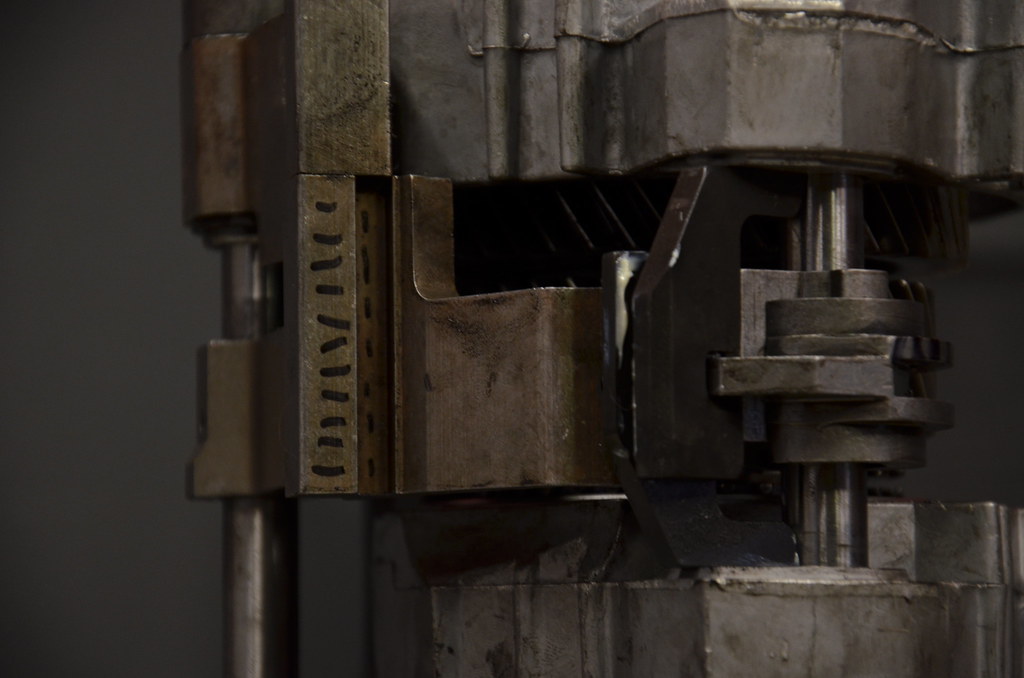

The stock 3.42 diff arrived today at RKT Performance for a rebuild and Motive 4.10 ring and pinion install. Rick sent over some pictures of the worn clutches and broken Belleville spring.

unnamed1 by Norbert Ogiba, on Flickr

unnamed1 by Norbert Ogiba, on Flickr

unnamed2 by Norbert Ogiba, on Flickr

unnamed2 by Norbert Ogiba, on Flickr

unnamed3 by Norbert Ogiba, on Flickr

unnamed3 by Norbert Ogiba, on Flickr

In addition to the Motive 4.10s it will be getting new C6Z06 clutches, springs, seals, and o-rings.

While I wait on T56 parts and the diff I think I’ll start to work on the torque tube. That will consist of inspection of the rubber couplers (guibos), bushings, and bearings. Last of the “must do” items is an LS7 clutch and flywheel. I am starting to get the itch to drive this thing.

Diff is all torn apart at RKT Performance.

unnamed7 by Norbert Ogiba, on Flickr

unnamed7 by Norbert Ogiba, on Flickr

LS7 clutch, flywheel, pressure plate, pilot bearing on order.

Torque tube guibos on order (stock replacements). Old ones looked generally ok but had some stress cracks starting up.

Polyurethane rear sway bar bushings on order.

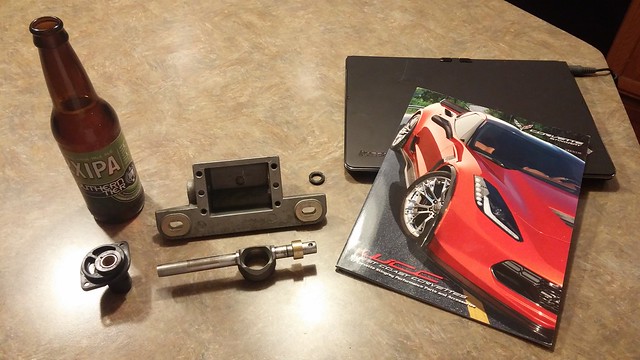

So while I wait for the diff to come back and other parts to come in, I had a friend make me some brass bushings for the C6 lower shift box.

After a long Monday at work followed by some snowmobiling, it was nice to come home to this and relax.

0206172108 by Norbert Ogiba, on Flickr

0206172108 by Norbert Ogiba, on Flickr

Pressed into retaining plastic

0206172109a by Norbert Ogiba, on Flickr

0206172109a by Norbert Ogiba, on Flickr

Great fitment on the larger (rear) bushing, only minor hand sanding needed.

0206172108a by Norbert Ogiba, on Flickr

0206172108a by Norbert Ogiba, on Flickr

The rear bushing needed more work to to fit correctly as it was too tight. It was taking forever to hand sand this stuff so I chucked up the shift rod in the CNC lathe (LOL) and got to it.

How much is it going to be when it’s for sale?

Lol. wanna buy it @Spam16v ? Not horribly tied to it but it’s paid for and doesn’t hurt to sit.

I am calling you out son.

Black on Black Crime

:bigtup: memegame on point

The transmission is back together, 4.10 diff came back from RKT56, torque tube is reassembled with new couplers, LS7 clutch and flywheel installed, drill mod done on new LS6 clutch slave…it was a busy weekend.

Trannies with Norb!

Nice work, I think I’m going to go with an LS7 clutch for my gto.

I ran the AC Delco Flywheel and LS7 clutch on the BMW, loved it. This time around I put in a LuK flywheel ($70 vs like $250 for the ACDelco branded unit). Both seem to be identical. We’ll see how it works out

I like your style! I’ll be looking to do the same!

Bunch of small updates, I have been working on this thing a couple days a week getting little things done.

Torque tube out

_DSC7628 by Norbert Ogiba, on Flickr

_DSC7628 by Norbert Ogiba, on Flickr

Removed the World’s Largest Snap Ring using a pair of needlenose

_DSC7631 by Norbert Ogiba, on Flickr

_DSC7631 by Norbert Ogiba, on Flickr

Driveshaft out, inspecting the 2 rubber couplers:

_DSC7686 by Norbert Ogiba, on Flickr

_DSC7686 by Norbert Ogiba, on Flickr

How cool is that! Made in West Germany! makes you wonder how old the tooling/mold is, and if it’s still in use today…has to be from the 80s, at the latest…

The originals had 115K on them and were in ok shape, but were starting to crack. The GM replacements were $180 EACH. Turns out there is a BMW application made by Febi/Bilstein that is a functionally identical but much less expensive.

_DSC7687 by Norbert Ogiba, on Flickr

_DSC7687 by Norbert Ogiba, on Flickr

Factory torque spec is fairly high on these, apparently I have shitty tools.

_DSC7692 by Norbert Ogiba, on Flickr

_DSC7692 by Norbert Ogiba, on Flickr

Ah, the good old BMW days, proper giubo orientation and loctite on fasteners

_DSC7693 by Norbert Ogiba, on Flickr

_DSC7693 by Norbert Ogiba, on Flickr

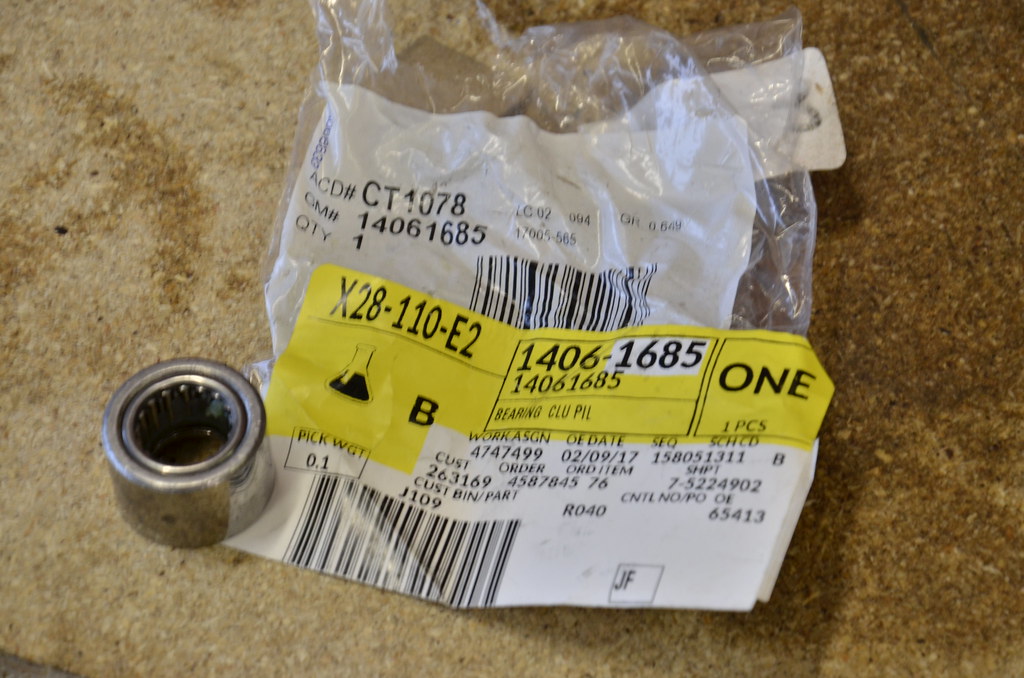

New pilot bearing

_DSC7689 by Norbert Ogiba, on Flickr

_DSC7689 by Norbert Ogiba, on Flickr

Drilled out the line on the new LS6 slave, before and after. The “after” is still a baby .125", LOL.

_DSC7677 by Norbert Ogiba, on Flickr

_DSC7677 by Norbert Ogiba, on Flickr

Took a break from mechanical work to refinish the original period correct N73 Magnesium wheels. These were a $3000 option back in the day and were fairly rare. I picked up another pair of rears to have a square 18x9.5" setup all the way around. I’ll probably end up using these as track wheels only.

_DSC7680 by Norbert Ogiba, on Flickr

_DSC7680 by Norbert Ogiba, on Flickr

Stock photo of Pfadt Trans mount vs stocker to hopefully knock down some of the wheel hop

2 mount by Norbert Ogiba, on Flickr

2 mount by Norbert Ogiba, on Flickr

LS7 Flywheel all degreased and ready to slam in

_DSC7695 by Norbert Ogiba, on Flickr

_DSC7695 by Norbert Ogiba, on Flickr

While reassembling the T56 I had some trouble lining up the shift rails on the guide pins, as the rails want to walk down when the trans is sitting vertically. Made some Sharpie marks on the rail blocks to be able to peek through the guide pin holes and get an idea of where they were. Worked like a charm.

_DSC7696 by Norbert Ogiba, on Flickr

_DSC7696 by Norbert Ogiba, on Flickr

_DSC7697 by Norbert Ogiba, on Flickr

_DSC7697 by Norbert Ogiba, on Flickr

Took a break from the monotony to go to Vegas and kick the shit out of some cars. Somehow it rained that day…in Vegas…in the desert…

_DSC7654 by Norbert Ogiba, on Flickr

_DSC7654 by Norbert Ogiba, on Flickr

_DSC7647 by Norbert Ogiba, on Flickr

_DSC7647 by Norbert Ogiba, on Flickr

_DSC7644 by Norbert Ogiba, on Flickr

_DSC7644 by Norbert Ogiba, on Flickr

_DSC7667 by Norbert Ogiba, on Flickr

_DSC7667 by Norbert Ogiba, on Flickr

_DSC7661 by Norbert Ogiba, on Flickr

_DSC7661 by Norbert Ogiba, on Flickr