had some help from my buddy Tom last night getting the cab rolled onto it’s back…

welded the remaining seams of the cab mounts to the floor pans, wire wheeled the entire bottom of the cab, and then coated in in rust encapsulater (knockoff POR15)

also got some goodies from Summit again, these leaf spring pads are only $6ea which is so cheap it didn’t make sense to make my own. hoping to mockup drivetrain over the weekend so I can get these welded to the rear axle.

Man, I love that this is getting constant progress. Nice work.

thanks! that makes two of us haha. For once I might start and finish a project all in one swoop instead of getting like 80% done and then tucking it in a corner to work on something else.

Looking good!

Weekend couldn’t have gone any better for the build.

Friday night I wire-wheeled the section of frame that’s under the cab in prep for rust encapsilater and chassis coat paint.

Saturday morning I did the rust encapsilater and cut my front frame braces out and then did two side jobs.

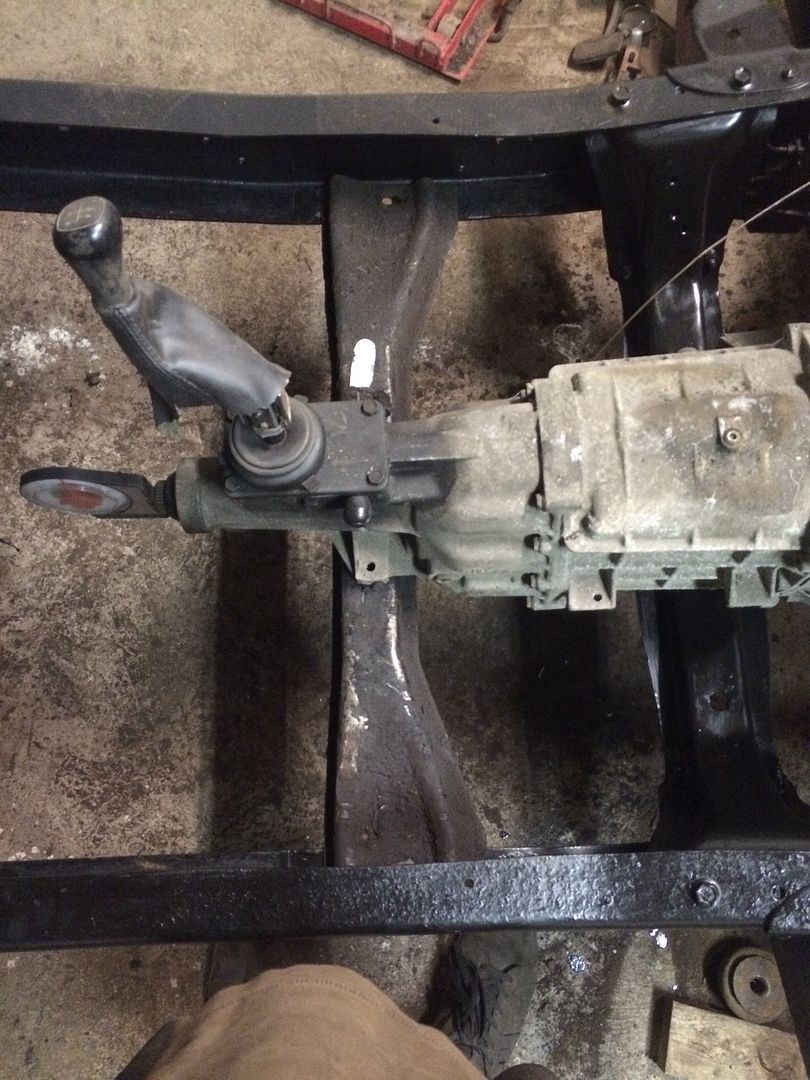

Sunday afternoon I went and removed the mustang cross member, steering rack, and lower control arms from the motor. Then swapped on the brand new crown vic mounts, and set the eng/trans in place. Grabbed the stock trans crossmember from when I pulled the C6 auto and as it turns out it’ll work as-is. Score again. Also, the stock speedo cable will mount right in the VSS from the T-45 and happens to already have the correct tooth count. YAY!

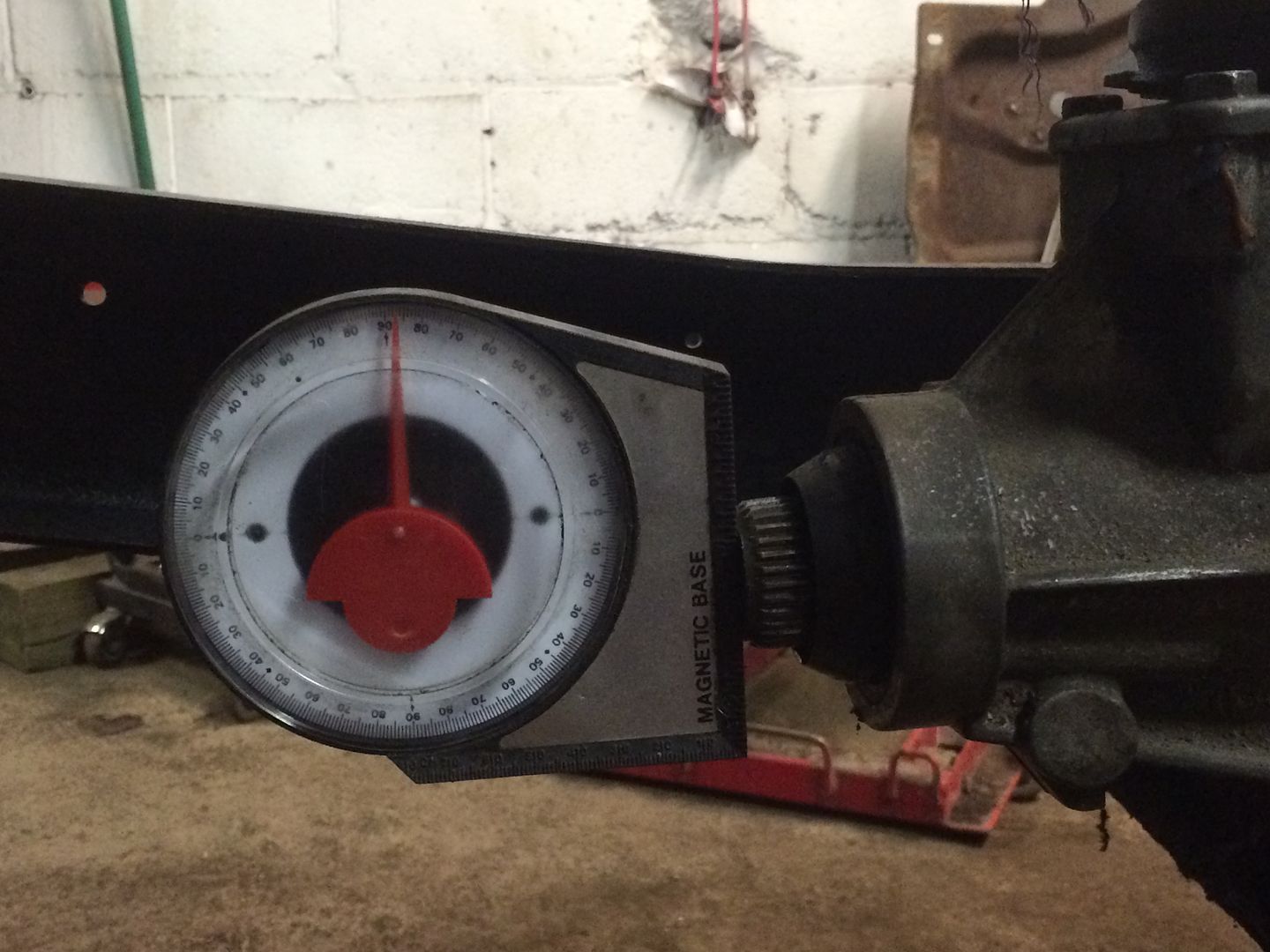

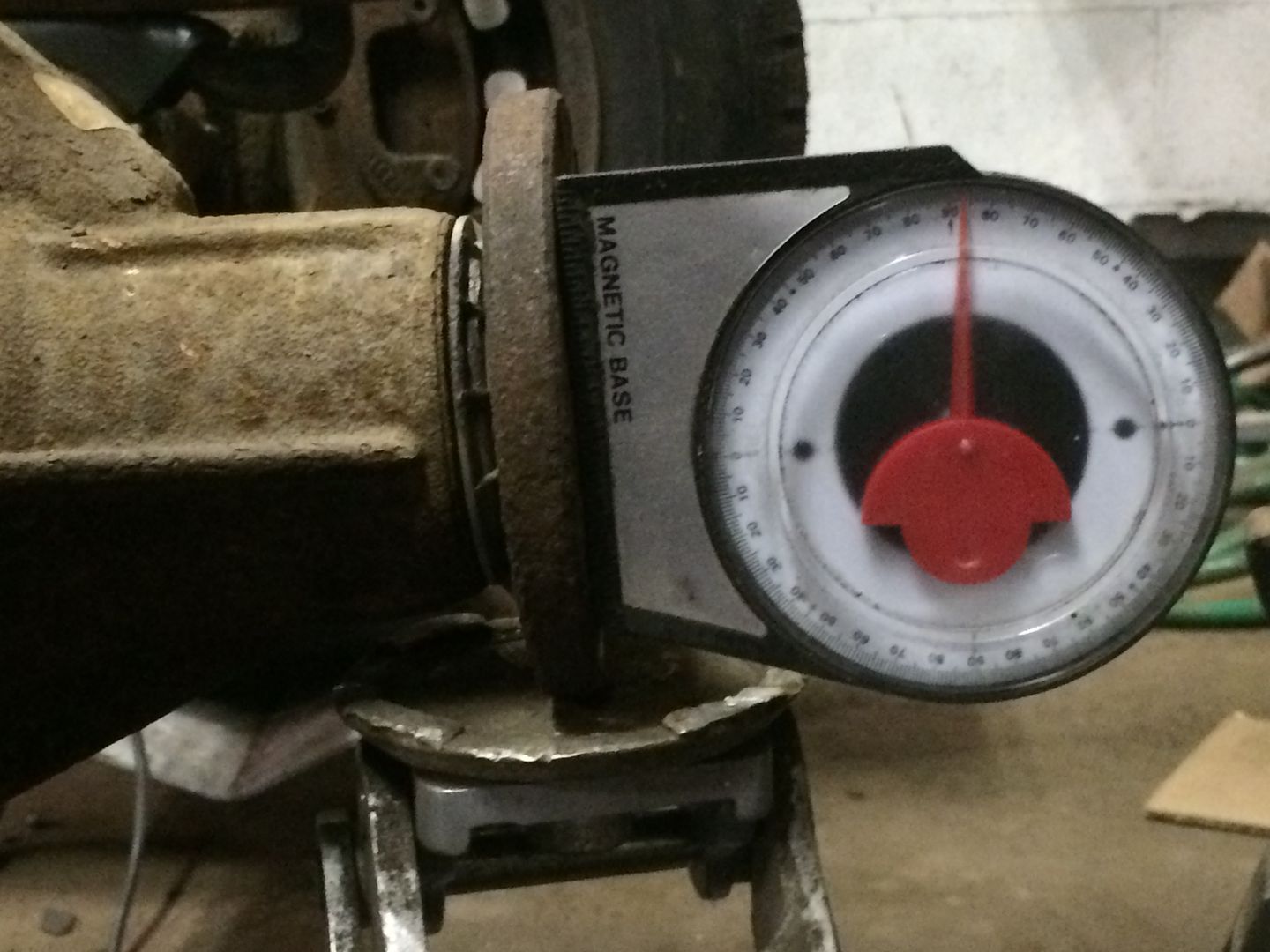

After dinner sunday I decided I wanted to get the rear axle situated. So I hacked off all the coil spring and 4-link parts and prepped for the leaf pads. Put the truck on wheel dollies so I could get the front wheels straight and start taking measurements. after about an hour and 20 mins I had everything where it needed to be including pinion angle set, and welded up the leaf pads. super happy to have gotten this far over the weekend. next thing to worry about is exhaust and oil filter…you’ll see why.

Right as I finished applying rust encapsilater before it started turning purple and black

After I had applied chassis coat

Engine and trans home

LUCKY

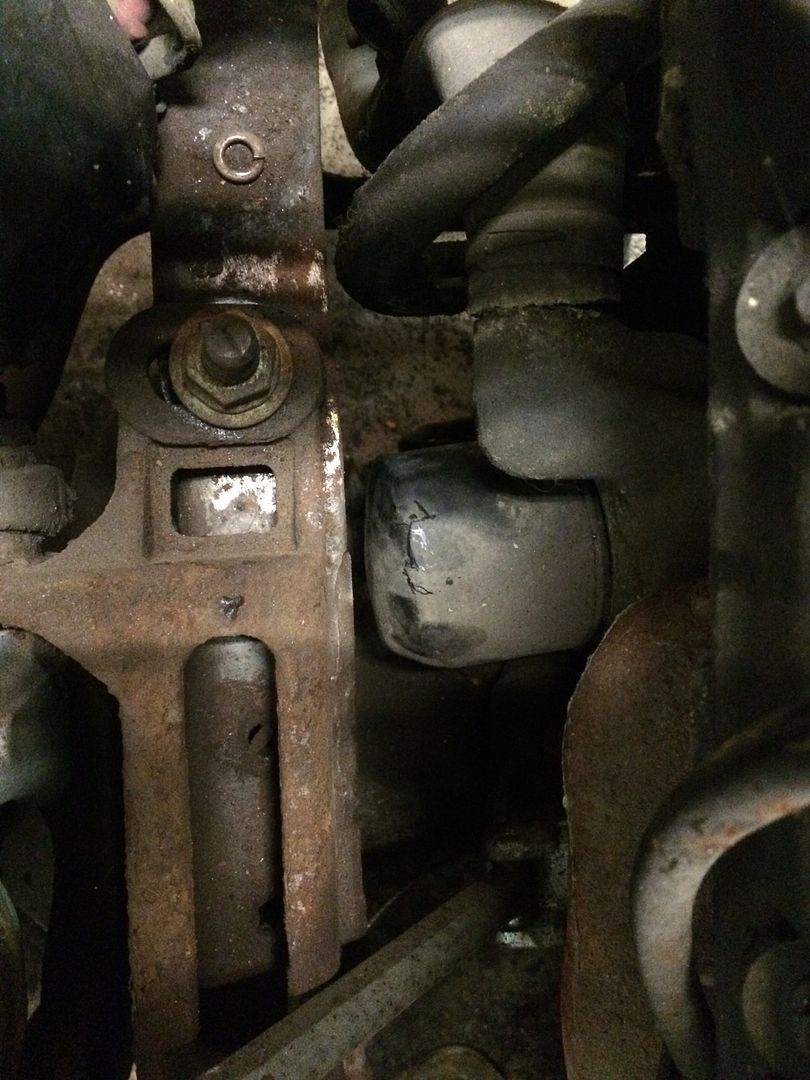

well, this might pose an issue…gonna need a 90* adapter or relocation setup

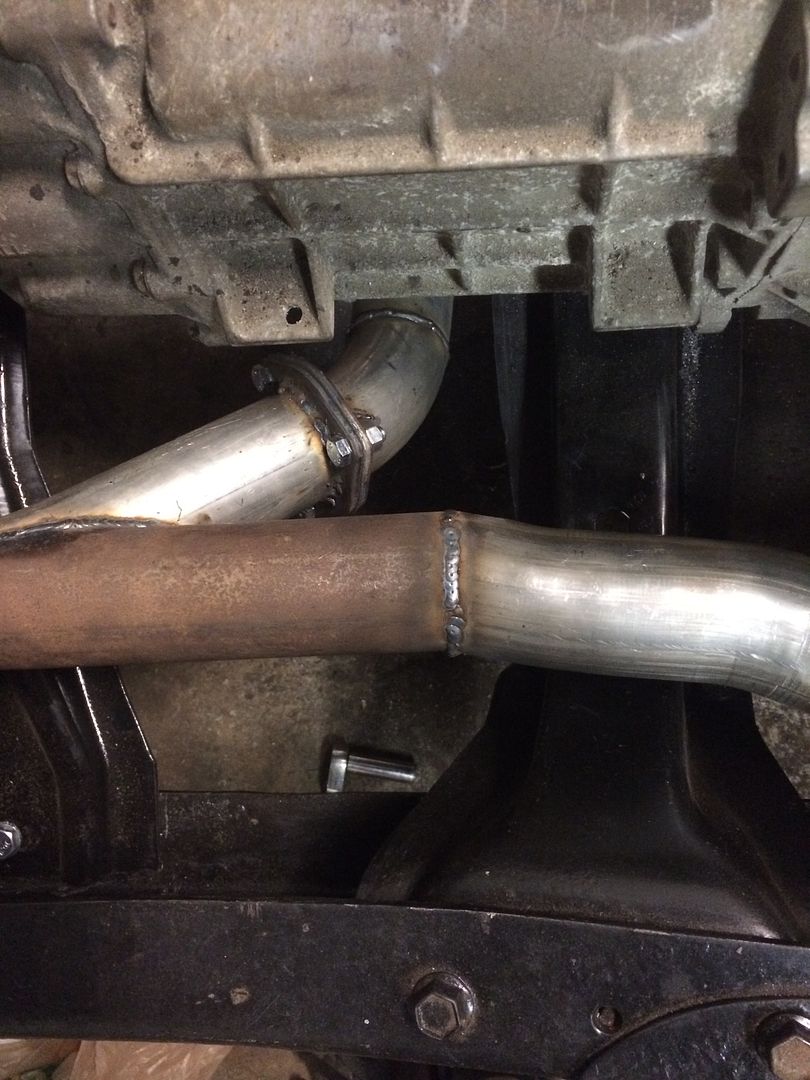

well, looks like mustang cat-delete mid pipes may not fit… might have to get some 2.5" bends and some flanges and make my own

Bye 4-link

leaf pads in place

setting angle

welded

always good work

very nice. filter relocation should work fine for you

Siiiiick. I have to come by and check this out!

Awesome. Really love this build.

doing boring shit now. except I am kinda mad that due to budget running out I have to run single exhaust instead of dual.

So, I decided against running a mid 60’s mustang tank mounted in the rear of the frame under the bed…because it’s $500 for a tank with an EFI sending unit in it. I’d also have to find a different rear bumper and convert to a flip-down plate to run a behind-plate fuel filler neck.

I instead am running an in-line fuel pump pulling from the stock fuel tank under the driver side of the cab and bed. This was closer to $100 in parts for a pump and inline fuel filter. issue now is, with that stock tank I don’t have room to run a driver side exhaust unless I go underneath the tank and then ground clearance is a concern. So I made up the intermediate pipes that come off the manifolds last night, but I need to cross under the trans and make a Y pipe to get the driver side connected to the passenger side and run one single pipe out the back on the passenger side.

Inline pump should work good.

You don’t plan on doing anything too crazy with it.

I went with a tank Inc tank with a sump because I was worried about starving the pump under cornering.

So, constantly waiting on parts and discovering more stuff I need…

to make a long story longer, I had asked summitracing’s tech dept about a set of “intermediate pipes” for a 98 mustang GT on the site…asking if they replaced the cat’s in an off-road situation. I was told “yes thats correct” so I ordered. Not knowing much about mustangs, I though I was just missing a donut gasket for the passenger side as both pipes that showed up have the ball-style end on them. Well, they didn’t fit as-is. I didn’t expect them to fit 100%, but they were like 130* off, aiming straight into the frame. I made some pie cuts in them to get them to play nicer, and THEN discovered they were actually meant to go at the ends of the cat/mid-pipe system for connecting off-the-shelf aftermarket mufflers to the stock cats. FML. So, on top of not being able to run dual exhaust, I’m not faily unhappy with the exhaust as a whole. good thing it’s cheap aluminized steel and I’ll want to revisit the exhaust in the future. At this point I’ll probably pay muffleman or some shit to build one next year.

anyways, I cut up some cheap U-bends and built a Y-pipe setup to a 35" glasspack and will have a turn-out before the rear wheel. I ordered a donut gasket and new hardware for the manifolds so I can make this work. I also welded the rear shock mounts to the axle, and flipped the Crown Vic rear swaybar upside-down and backwars so I can mount endlinks to the frame behind. quick measuring and Pirite(Luke) says ford taurus rear links should be perfect, so he’s ordering me a pair through work (if they don’t fit he can send them back fo free).

Thought I took more pics but I guess not. here’s what I did take.

I left one weld as just a couple tacks so I have a place to put a pair of flanges so this thing comes apart for future maintenance and repair.

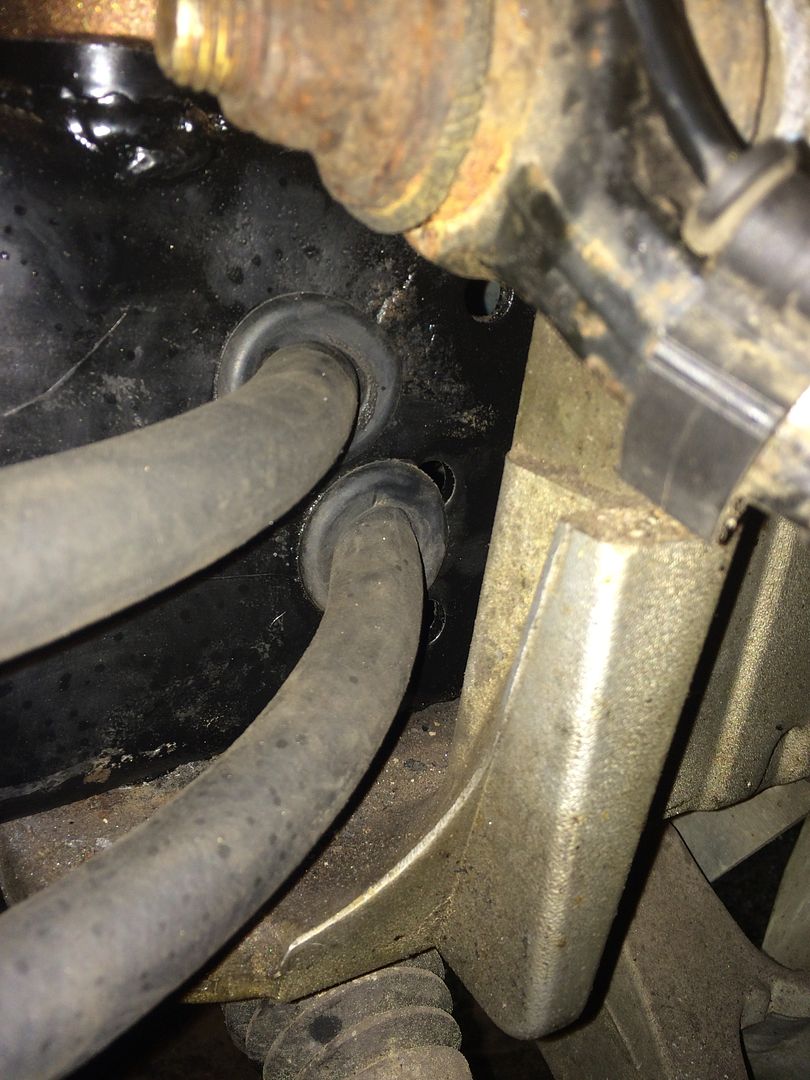

Haven’t posted much cause for a while it was looking like negative progress. I pulled the motor and trans back out, pullled the crown vic front suspension back out, wire wheeled the front 1/3rd of the frame, POR15’d it, blasted some of the brackets and had Kamilitaryman Powdercoat them for me, and then re-installed everything for hopefully the last time. Finished the exhaust, installed the oil filter relocation kit (drilled two holes in frame and installed grommets to pass the lines through so they wouldn’t be kinked) and installed a short throw shifter (since I’m gonna have like an 18" lever)

hitting the junkyard saturday AM to look for a driveshaft I can use and clip some pigtails for stuff that’s damaged or missing from my wiring harness…might flip the cab back into place tonight to start wirewheeling the back 1/3 of the frame for POR15

That wrinkly copper color you chose looks like it belong on this project! What else are we going to lay powder on?

Looking good. :tup: to progress. Not going to at least paint the exhaust?

Dan

I’m so unhappy with the exhaust I probably won’t.

I’m basically going to give myself an excuse to re-do it next year in stainless and use proper bends instead of accidentally buying the wrong parts and making them fit. Or I’ll go to mufflerman and pay a few hundred to not deal with it and have beautiful mandrel bent stainless exhaust. we’ll see.

Gotcha. I think Id still blast some BBQ black on it so its not orange between now and when you redo it.

Dan

We have a running joke in my garage. “add it to the next winter list” its basically when we know we are taking a shortcut but will likely NEVER make the time to do anything about it. Every build has some!

I didn’t want to say anything there Nick :snicker: