Think you need to give me a call when you start working on this. I love welding and would love to check it out

Yes.

Holymonstertruck

…giggity…

I forget how massive those are every single time I look at a set

Forgot that im goin to the regatta on saturday, but im leaving early so im gonna try for sunday

I was supposed to go, but suck at reading at dates.

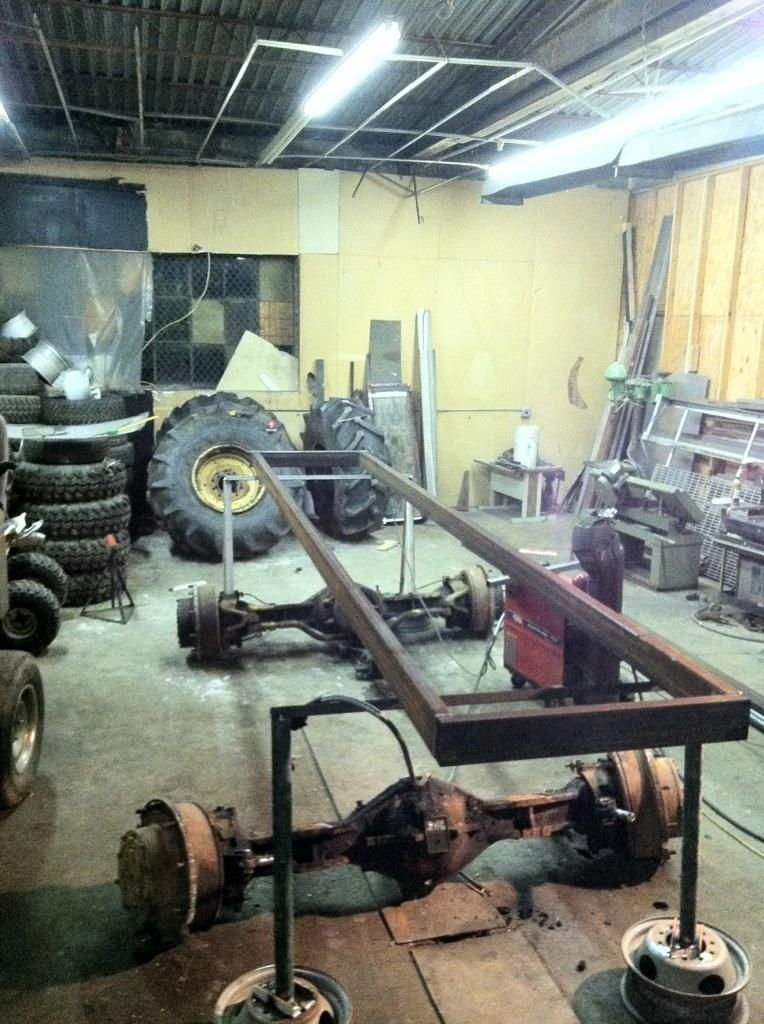

He’s some pics of the progress from earlier this week…

I obviously have to re center the wheels, Cut up a test piece an i fit perfectly

not sure why the pictures make them look shitty, but the cuts were very clean…

so i, just gonna cut out the factor center and replace it with this, but made of 3/8"

And i got the main frame shimmed up, leveled, squared and welded up (laser lever)

Going to try to get some more done tomorrow if i get home in time.

This is by far my favorite build.

Sent from my C771 using Tapatalk 2

Klein steel was where i got my metal. Its insanely cheap there.

edit:

don’t use the website to buy anything, that shits way over priced. Go to the building and go around to the back, you’ll see a garage door and a small man door, when you walk in there will be a small office room on your left. Those guys will hook you up.

They have a HUGE showroom floor of all the stuff you can buy

thats where i get all mine from… surplus rack :tup:

FINNALY got the bender and notcher setup… spent a couple hrs last night and got some tubes tacked up. gonna X the center and put two verticles on the ends today… then finish up the other side

Big tires = big what?

sizing of rect and tubing? how are you holding things down when you finish weld it?

5x2 rec tubing… what do you mean by hold things down?

Chassis table/jig with plenty of supports to hold things in place to keep the metal from pulling/twisting. Refer to my 47 build.

Just laying it out on the floor and welding it together would be a pretty bad idea

i just tacked eveything to the homemade stands. No floor will ever be perfect so i built the stands and painted marks on the floor where they sit accounting for the offset of the floor slope using a laser level. But bein that its just a mud truck, im not too concerned about 1/8 - 3/16. Although, so far everthing is less than 1/16th.

alot of people just lay it on the floor however i find it to be a pretty bad idea. having a table helps with leveling everything and measurements, making sure things are square. then when it comes to finish weld it helps hold things in place to reduce warpage / pulling and twisting. it only cost me $385 to build the ibeam chassis table i have and i can get it perfectly level on a ground that is un even by ~6 inches. not a bad idea to build one…

update"

Cnc table has been plagued with issues for the last month since I moved it into the new shop… Finally back up and running . Picked up the 1/4 steel sheets for the other wheel centers and brackets. As well as the 2" 3/16 wall tube an joints for the 4 links

So with any luck the frame should be turned into a rolling chassis (on some big f*cking wheels) by sunday…