3.62s are in, donated from E46 M3

We’re getting some “nice” weather (not 20*F) this week so I’ll be spending some more time chipping away at things.

Last night I got a few things done.

Removed AC lines, made up a small aluminum block off plate for the lines going into the firewall/evaporator to prevent them getting gunked up with dirt and such. While I was at it I removed the secondary air injection pump and the AC dryer, both in the fenderwell. I’m left with 2 nice big holes there now so I may use one of them for some fresh air to the intake.

I also buttoned up the front accessory drive. I had routed the belt incorrectly, so I fixed that and make sure it all rotated smoothly.

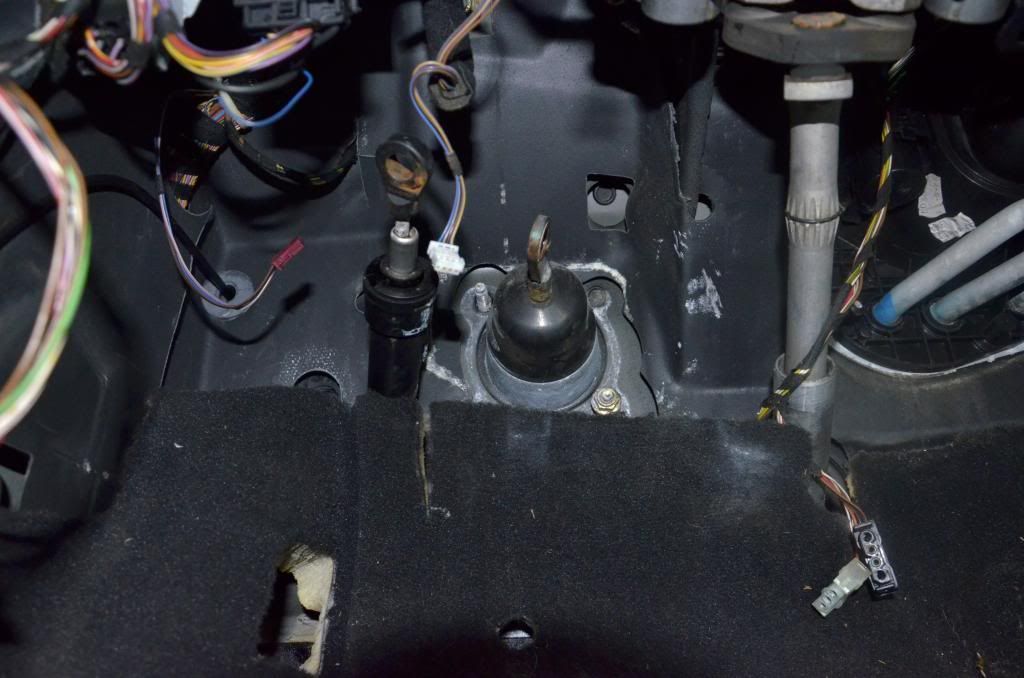

Finished cutting the threads on the shifter with the die, installed the locking nut and knob. If I ever end up with spare time when it’s all done I’m considering making a 2nd shifter handle (same brushed finish, but taller) for fun.

Soaked the engine bay in purple power, gave everything a good scrub. Also cleaned and reinstalled all the heat shields around the front thrust arms that I had removed when pulling the M62.

Cleaned up the valve covers and intake manifold with purple power as well. Halfway through the first valve cover I realized it was started to eat some of the wrinkle finish I put on there, so I may have to respray it.

Installed the rocker pedestals, rockers, pushrods. Gave the engine a few partial turns and they’re all moving smoothly. I didn’t expect any PTV problems with my stock LS2 Vette cam and milled heads but it’s nice to know for certain that I’m good.

My T56 arrives in Texas for the rebuild today, so I’m expecting a call late this week or early next week. In the meantime I still need to buy a pilot bearing (small f-body style one) and new slave cyl, as well as an f-body clutch line since it fits the BMW master with some modification.

In the meantime I may jump in headfirst and start rebuilding my M5 diff. After doing much research I’m more confident about rebuilding the LSD portion. Setting up the ring and pinion is a different story though, I will leave that to a professional. Who sets up gears/rear ends locally? I would probably have them press the new pinion in and check the backlash on the gears.

The internals of my M5 diff are fully disassembled. It’s an easy job for anyone undertaking a clutch disc replacement, just go slowly. Cleaned the internal LSD core parts, they’re bagged and tagged, while the spool and spool lid are soaking in Purple power along with the output covers. I was able to remove the output shaft bearings very easily with a cutoff wheel and gentle prying. The inner races were much more difficult, requiring lots of patient grinding and tapping. I was able to eventually get them “thin” enough to where the chisel split them. No damage to the surface that the inner race rides on. Unfortunately I’m at a standstill for rebuilding the diff as I still am waiting on new bearings, races, pinion seals, etc. Also spoke with Jim Blanton and he’s out of stock for clutches and dog ears (#$%^&) so I’ll call up a few other places today and see who has them. My dog ears were worn evenly, no ridges or scars, but the clutches were nearly smooth. I also was able to remove the ring gear by getting creative with my vise and a ½” thick rod to brace it. Those bolts are in TIGHT! Tonight I may be able to install the new 3.62 ring gear at the very least.

Regarding the pinion, what’s the procedure for installing the new 3.62 pinion? Removing the old one is not a big deal (mark/paint nut, remove nut, press out old pinion, replace seals and crush sleeve and bearings, replace pinion, re-torque). However, I’d like to know how to set it up with the new pinion. Does the new 3.62 pinion still “re-use” the position of the old one via the paint marks on the nut, aka is it set to the exact same pinion depth? I’m just curious as to what the procedure is. I have no way of checking backlash either (no dial indicator) so I will have to take it somewhere to have them check the mesh pattern for me and adjust if necessary once it’s all assembled.

I also messed around with the pedal assembly in the car. I bought an auto pedal assembly (but DBC) out of a late 90s 528i a few weeks ago, so I spent the last few hours of the evening removing the 6 speed pedals, swapping over the clutch pedal, and transferring over a few other things. In retrospect I “probably” could have just transferred the DBC BMW gas pedal to my set, but my 6 speed pedal bracket was pretty corroded and oxidized, so I’m glad I swapped it. I also removed the connection between the clutch master cylinder and the clutch line, but a good portion of the line is hard underneath the carpet and behind the firewall, and I was too tired to try to pull it out. I won’t need the line again so I may just cut it and pull it out from each side for ease of removal. The E39 is built like a tank under the dashboard. Welded tubular steel dash support, tons of foam throughout to insulate, leather shroud covering the steering shaft cavity so you can’t see into the dash when you adjust the wheel…pretty cool stuff.

So, I stopped into Denny’s Driveshaft on lunch to ask them a few things and get a quote.

http://www.dennysdriveshaft.com/index.html

I was told that they do not modify OEM driveshafts at all, which surprised me, considering how reputable of a shop they are. They said they’d be more than happy to make me a new one, but that doesn’t seem economical to me. It may have something to do with the fact that the money is probably made making new shafts, not doing a quick chop and weld on an existing unit.

Ironically the guy behind the counter is doing a TH350/SBC or LS swap into his ’94 325.

He also brought up the fact that even if they could modify the driveshaft, it’s still a slip connection at both ends. I recall reading about this in another E39 LS swap thread and remember that apparently it wasn’t causing an issue in street use, but I don’t want to risk anything down the road as the car will see many long trips at sustained speed (85 mph+ for hours at a time). The stock E39 trans had a rigid 3 bolt connection at the front, a CSB in the middle by the u-joint splitting the halves, and a slip connection at the rear into the diff. The new T56 to driveshaft connection is slip joint, and I want to retain the CSB as well as the rear OEM BMW slip joint.

I’ll search for more info on that now, but anyone have any input on this?

removed the stock BMW DBW pedal.

brake and clutch master cylinder connections.

incredible amount of insulation in this car. the carpet is bonded to regular style yellow foam, and underneath is a hard-expanded foam in light green.

the pile of shit within the car grows…

installed the standard DBC plastic pedal

the stock hydraulic connection to the 540 clutch master cylinder.

---------- Post added at 10:41 AM ---------- Previous post was at 10:23 AM ----------

spent the last few days tearing down and cleaning the M5 diff.

the victim. got a good deal on it, but it had no service history, condition was listed as “we left this sitting outside for a year with no output stubs in it, no warranty, etc etc”.

whoever pulled the diff didn’t unbolt it, they just sheared the mounts. this car was probably in a severe wreck for them not to care like that.

differential side of the driveshaft.

sheared differential end of the driveshaft.

internal spool

E34 540i flanges

the output covers before removal. output shims are underneath.

keeping each output shim with its respective cover

old output seals, to be replaced

internal spool removed

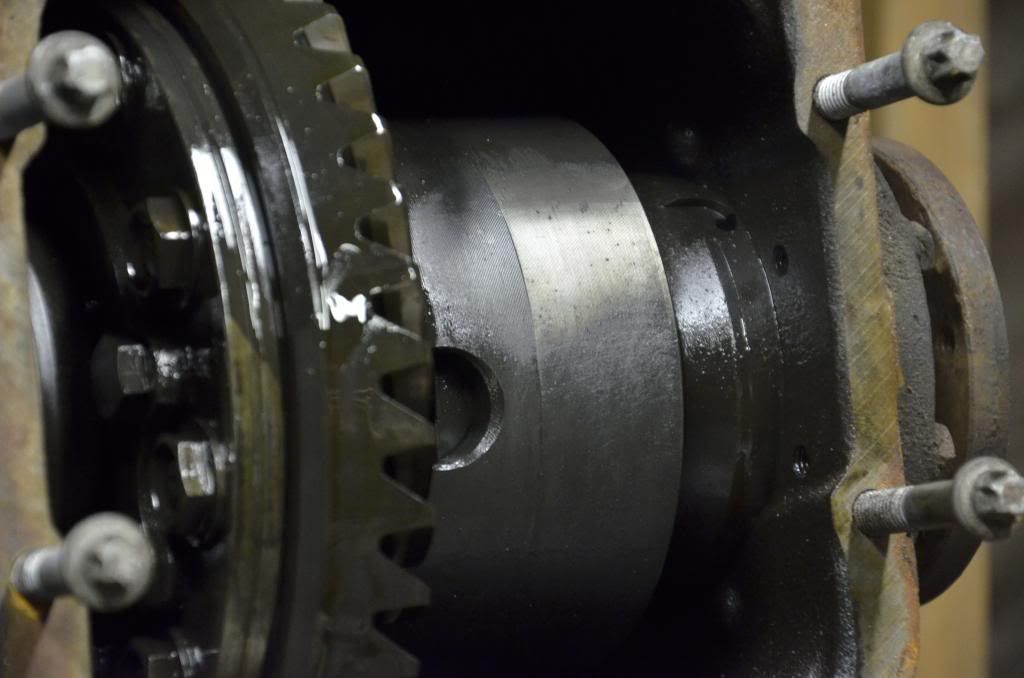

hypoid pinion gear. i thought you needed a press to remove it, but i was able to get it out with a rubber mallet and piece of wood.

---------- Post added at 11:23 AM ---------- Previous post was at 10:41 AM ----------

Once the spool lid is removed, there’s always the top oil washer that sticks to it.

Dog bones and gears.

Half of the clutch discs and “pressure plate” as I call it.

Exploded view of the spool internals.

Bagged and tagged.

Spool with all internals removed.

OEM 3.15 ring gear removed.

Lots of loctite used in the OEM setup.

Output cover, bearing race, and seal removed

Output cover cleaned up a bit.

I laid the 3.62 ring gear on the spool case and gently tapped it on with a rubber mallet. It went on about 80% of the way and then just stopped. I used the bolts to pull it fully on in an alternating pattern to avoid cocking it, and then removed the bolts to clean them up.

I laid the case with the cover side down, put a few wood blocks under it to catch the pinion, and tapped the pinion out after removing the nut with the impact.

Pinion seal being removed.

Front pinion bearing

Front pinion race

3.15 pinion shown “as assembled” with old bearings.

Rear pinion race and pinion shim.

the last i’ll see of the internals, hopefully for a while.

brand new from GM, 2004 LS1 GTO deflection tray and oil pickup tube installed

i also pressed in the freeze plug to block off the original van dipstick hole, which is cast into the block. the new GTO dipstick pokes through a hole machined in the oil pan. i would have installed the dipstick too, but it goes on after the exhaust, which Breetime is still welding up for me.

Why not have fleet pride extend the driveshaft, if you give them dimensions they should be able too.

Cant wait to take a ride in this thing! Let me know if you need a set of helping hands

thanks, i wasn’t sure who did that work around here.

thanks!

Dennys isn’t that expensive for custom driveshafts.

If the price between Fleetpride and Dennys isn’t more then a few hundred its a simple choice.

You got the tranny built why not upgrade the driveshaft also?

yup, this.

Adam, with the awd avenger, he’s on the boards here, had his extended by fleet pride and they did a very nice job. thats why i recommend them. Build looks great norb!

The 540i shaft is nearly identical to the M5 shaft minus a few inch difference in length; many people are putting down 500+ wheel with no problems. I want to retain the 2 piece configuration to avoid NVH issues as well as critical speed due to length.

Thanks, didn’t know Fleet pride did shafts, I thought they were just diesel maintenance. just down the road from me too.

No problem!

Denny’s does great work but they take forever

Nice work!

I had fleet pride build me a driveshaft for my e36 after i kept breaking them at 750whp+ My stock 120k mile driveshaft lasted at 650whp with no problems. the m5 shaft is larger then the e36, so im fairly confident you will be fine. also try to keep it 2pc with the center support bearing if you want to avoid harmonics at higher speeds. I wouldnt worry about having 2 slips because the CSP will be holding the shaft in place.

they come with a good warrenty though. my friend snapped one of their shafts in half, they made him another one no charge and had it back to him with a pretty quick turn around. this was a few years back but i would think that hasnt changed.

Depends on the shaft, some have a lifetime warrenty, not sure about all the models though. (This does not include ends, just the shaft itself).