MISTERTWOSINISTER asked me to help him with his 3S-GTE Turbo swap into a 5SFE NA car this past week. Essentially we had to rewire the 3S-GTE ECU Plug “A” to work with the NA body harness. It’s seven wires, no big deal.

But, after the ECU was wired in it would not throw a check engine light during start-up. After double checking the wiring before did it, triple checked it after we had no Check Engine light, and making a few calls to Waide (an MR2 swap guru in Canada), I was still pretty confident we had a bad ECU. So I opened it up and discovered that components C810 was bad:

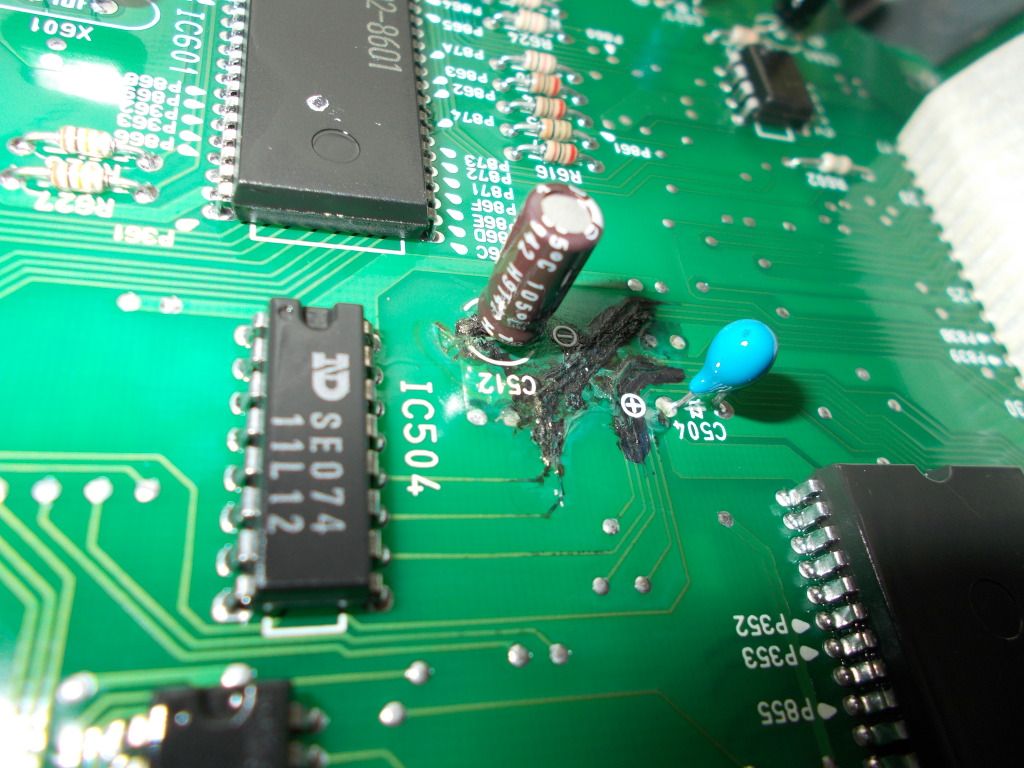

As well as C512:

This condition is known as “Capacitor plague.” Over time the capacitor literally “cooks” which leads to leaking electrolyte. I have dealt with this kind of thing before and some may recall I did this repair on sobo’s cluster. This is NOT a result of bad splicing or mixing up wiring…because this simply was not the case.

I removed the bad parts to reveal the affected areas. You can see the traces around C512 are corroded as well.

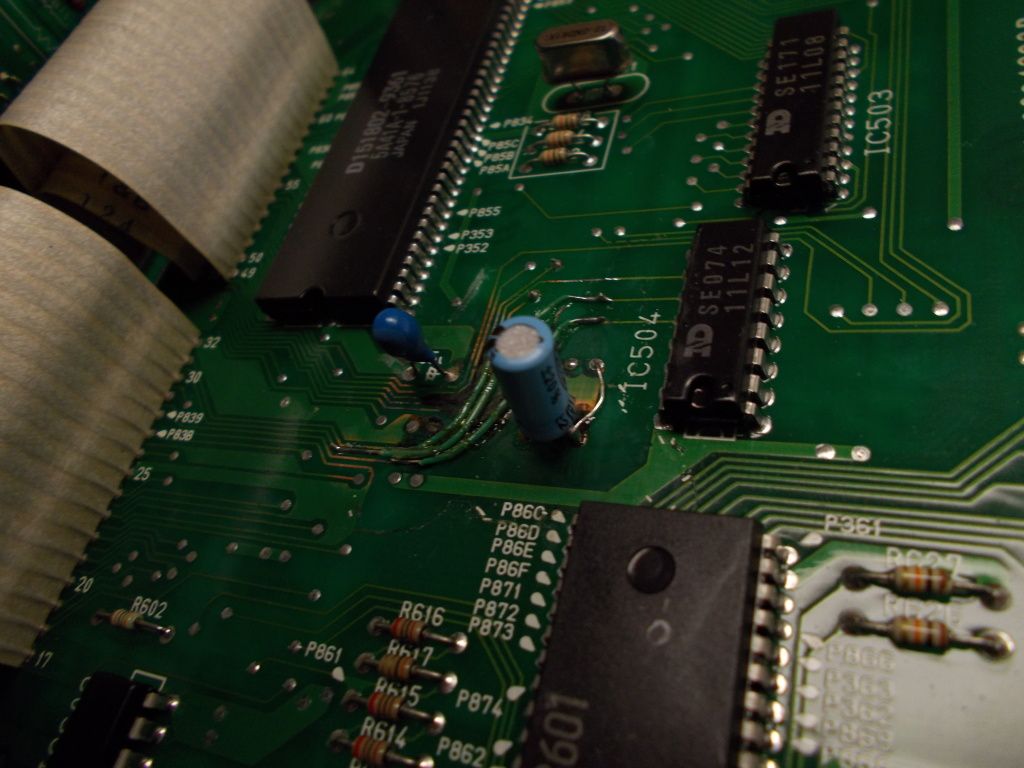

I removed some of the solder resist (Top green layer over the copper traces) so I could perform a continuity check to verify the connections are still good. Well, they were not. There were 6 traces corroded away that need to be fixed as well as the ground plane was no longer connected.

I replaced the Cap with a new 10uF 35 V one. Due to time constraints I opted for whatever Radio Shack had. It would be a good idea to replace ALL the caps with Tantalum caps which can be purchased here: DigiKey Corp.

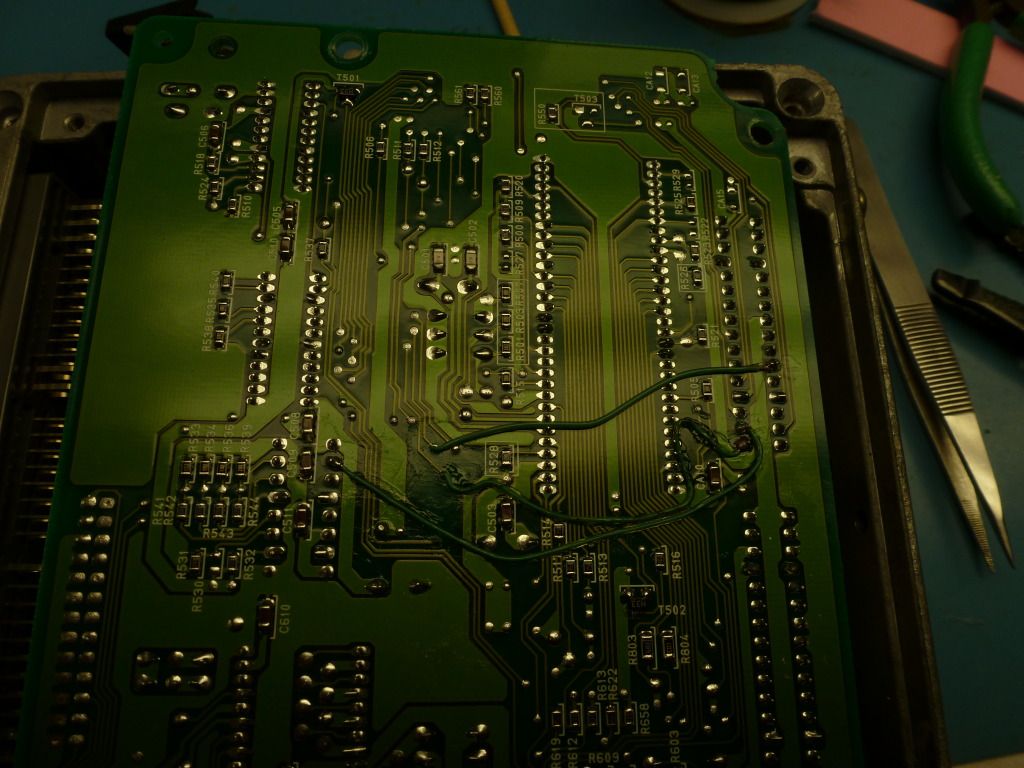

The jumpers are a 24 AWG heat seal wire. Essentially the wire is coated with hot glue. You apply heat to the wire insulation and it literally glues the wire in place.

Rather than run traces on the back side I was able to figure out where the broken traces where suppose to go. So I went point-to-point. It is much easier to solder in place this way.

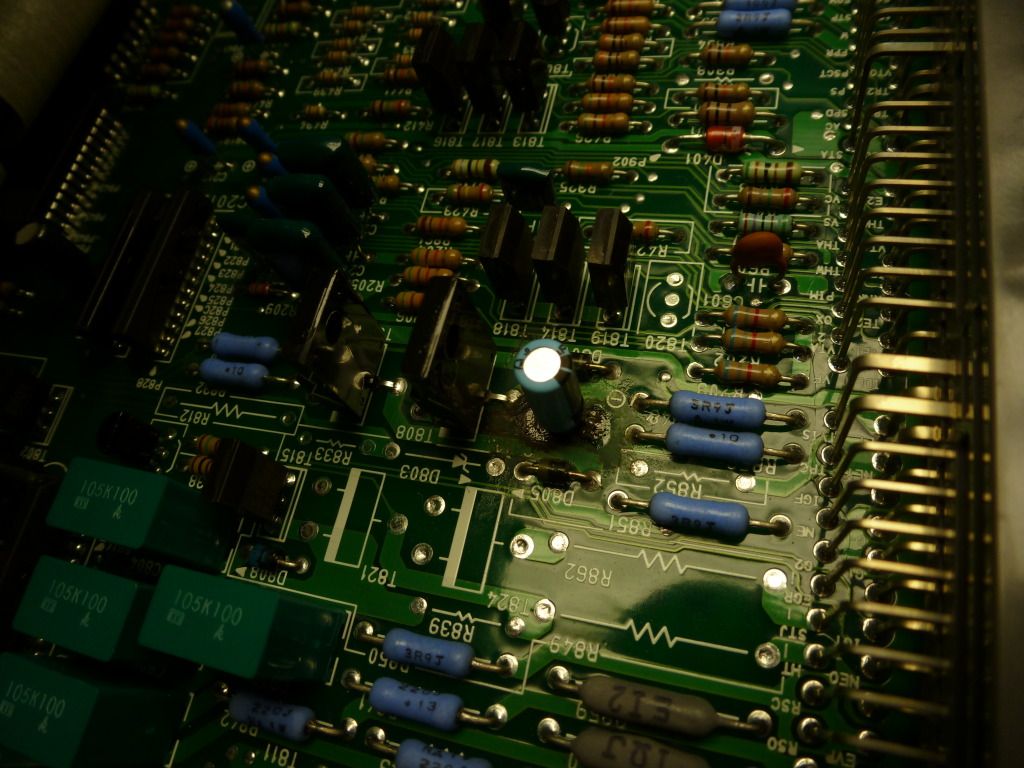

I then moved to C810. There is also something funky here. The difference with this trace is that it is an “Inner layer” meaning the copper traces is insider the PCB. This is common on multi-layer PCBs. Here you can see the trace “Popped” like a fuse.

I replaced the cap and again ran a jumper to the appropriate location.

Once everything was back together we installed it and everything was back to working properly.

So, anyone else having issue with a swap, potentially not throwing the check engine light at ACC, crack open that ECU and look for some blackness.