Good work.

Doctor, you are WAAYYYY off… Wire EDM is super slow by comparison to Laser Cutting (including setup time). Plus the holes (as mentioned by Newman) require unreasonable setup time for EACH piece since the holes need to be located for each piece. Laser can do multiple pieces from a single sheet with out any setup except locating the entire sheet. Anybody who suggest EDM for a manufacturing process of this part is completely clueless. Can it be done? absolutely,…is it the best option? Nope.

Since when is Laser a “snails pace”? Gauranteed it’s faster/cheaper than EDM and it’s done locally.

There are many approaches any part can be machined/cut… but Wire EDM is about as ridiculous as my suggesting “Why didn’t you just have the part pour cast?”

Since I expect some sort of clueless meathead response from you…Please list the local contact for said manufacturer who can do this part faster and cheaper than laser.

The only pieces i would even think of using EDM would be cutting of thick metals that require tight tolerances(i.e. 3/4"+ thick with .001" Tolerances) or exotic metals.

On-Topic:

HRK, the parts looks good, i like the flames better.

this was odd. I read this thread, then like a hour lateri was at the gas station getting a gatorade & i see this parked :lol: wierd

when i have the V8 pieces done in stainless, im going to have them done in that style emblem

but first i gotta find a good image file to convert to cad

-

Ok, I could have those burned locally at Ascension in 2 weeks.

-

He sent it to Nova Scotia because it was the cheapest. Do you realize what that part would cost if it were EDMd locally? easily 100 dollars per. EASILY. I know you have a viper and a lot of money so you can afford to do things the wrong way, but not everyone can.

-

You should get used to being wrong, because it seems to happen a lot.

Sorry for going OT. The parts look nice. I think you should look into a place that isn’t going to slam them out the door so fast if you want a better burn.

try a local HVAC shop with a plasma or water cutter. The plasma would require alot of slag grinding but i know theres at least one shop with a water setup which would be more expensive but if you wanna go the stainless route would be good to keep the finished product clean.

parts look great, good job

They aren’t my style, but props for designing & building a quality piece.

LOL, go back and read my post again, you have the entire thing backwards, and missed the part about comparing the time it took to to actually get them to do the job. Laser=Fast, Wire=Slow (as far as actual time in the machine), that I have not been arguing whatsoever. I have only been arguing the actual return time on the product from when you give them the job to when you have it in your hand. Their are fewer shops doing laser here than wire, as a result you will be waiting longer for the laser cut part than a wired part, regardless of the fact it is actually cut out faster. The EDM part will likely make it into the machine much, much sooner, and as a result probably be done sooner for a small part even taking into consideration the time difference to finish it. Now do you see what I am saying?

We arent talking many pieces here, time in the machine doesnt mean much of anything in comparison to the time to wait for the machine if you are in a hurry. And I didnt say cheaper, I just said close in price, and with a quick turnaround. And just for shis, I will ask the machine shop tomorrow how backed up their Wire is, and how long they think it would take to put a part in my hands. Want to take bets? I bet within 5 phone calls I could have one by Friday next week.

Geeze, considering how much everyone likes to read into my posts and comments, cant they at least read them CORRECTLY?

Thats fine, and thats not bad. I am however used to dealing with things that need to be completed in a matter of a couple days. I dont know of any shop w/laser cutting that can get in a small job that quickly. For EDM, I know quite a few. If time is not an issue, then hey- wait it out. I just made a suggestion for a different approach that could be done locally and with a quick turnaround if need be.

- He sent it to Nova Scotia because it was the cheapest. Do you realize what that part would cost if it were EDMd locally? easily 100 dollars per. EASILY.

Yes, this is certainly a factor. The people I deal with want products yesterday in many cases, and will pay for it. Fastest overall isnt always the cheapest or easiest, and I can accept that. I didnt see any mention in here about what he paid… but if the cost savings was worth the wait to him, thats fine too, though I woulnt expect it to be very different when talking about a 1-off peice done locally in either case. Sending a file out to Nova Scotia and waiting in line forever to see your part certainly SHOULD be cheaper, its basically a back-burner job.

- You should get used to being wrong, because it seems to happen a lot.

If being wrong continues to make me money with products that work exactly like they should, and my customers remain happy… than I’ll love being wrong for the rest of my life.

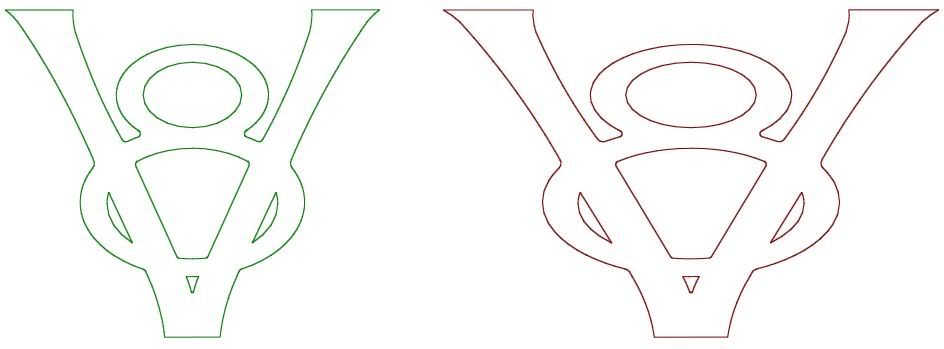

redid teh original design to be a bit more “retro”

it will be used as a stiffener on hairpins, so the design had to have some meat to the “V”

brown is the original redone, green is the same part, just constrained to 6" wide. ill most likely be using the green one for the hairpins.

$3.40 each set +shipping & some duty

all other quotes were between $12 and $100+, with the average between them all being something like $65 each, the one company wanted $98 each set, and they wanted to cnc plasma them instead of laser them as requested.

But cnc plasma wouldnt have given me corners with a .01" diameter ![]()