While it’s in this state, are you going to add some bracing or weld some of the seams to get the body more rigid and flex-resistant?

Maybe if i have the underbody soda-blasted, I will then, However, I think I am putting a 10 point+ cage in her for rigidity…

Mr. Newman. When you finished tacking in your patch panels to the floor do you have to run a bead all the way around before the seam sealer or will it hold up by itself from moisture?

Nice progress BTW.

you guys need to work on your reading skills. ![]()

Well dere ya go raht dere.

![]() Ha! I meant

Ha! I meant

a) Tack + Seam Sealer = Good Enough

b) Tack + Weld Bead + Seam Sealer = Better

Who sayz i dunt reed goud?

yea, but i think he should seal the seams first.

i hate you guys.

<3

yesterday, tonight, and tomorrow all look like they will be spent grinding rust and welding. Not a lot to report on that front.

However…

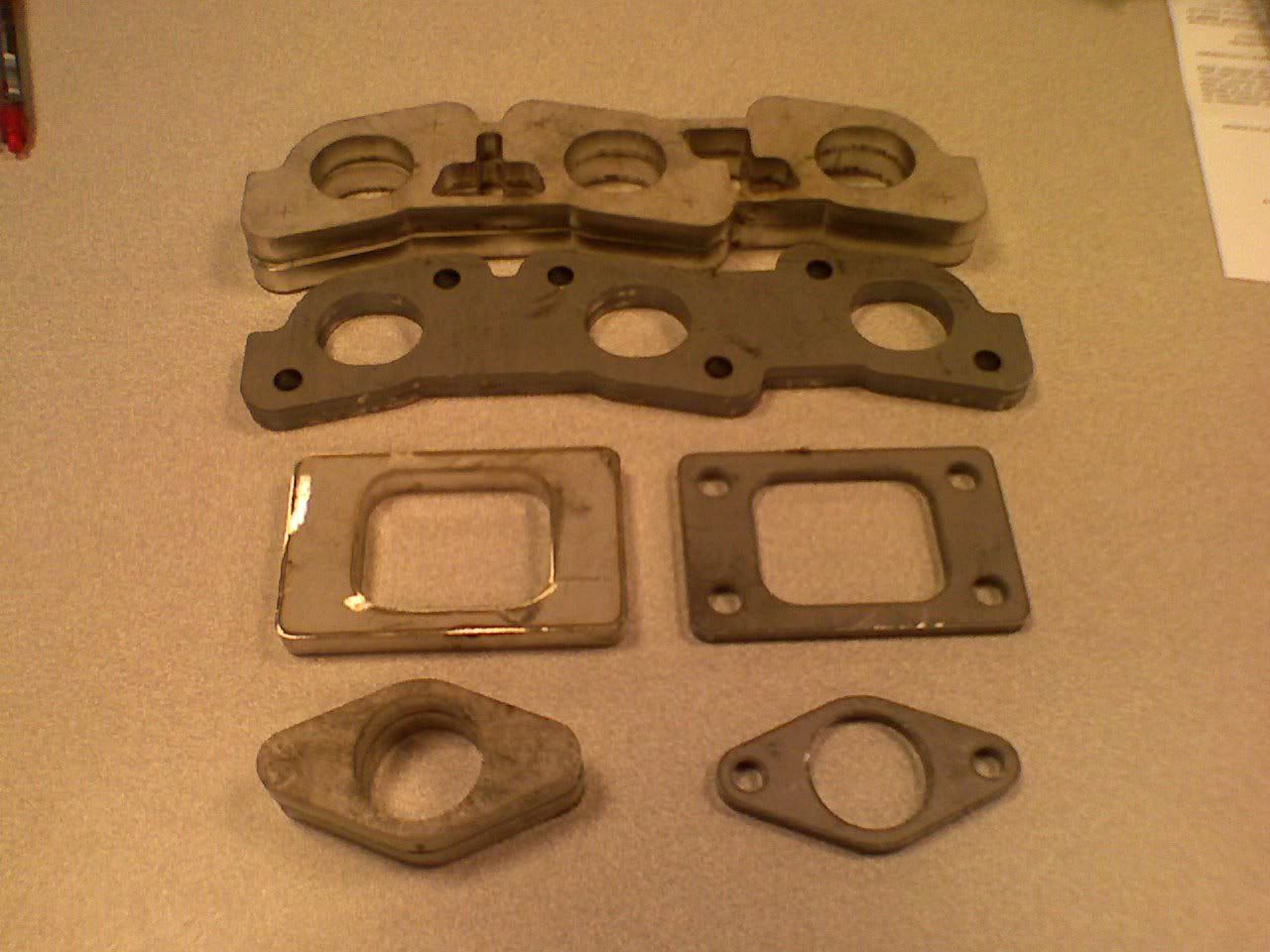

2 sets one for mockup/jig one for the final product.

1/4 Mild steel

1/2" 304SS

Compliments of Derrick Corporation. Holla.

why half inch SS?? that is one hell of a thick flange

by the time it’s welded, then machined, it will probably be around 3/8. It’s already bowed just from the laser. Note no holes in the SS, it’s too thick to get a good laser hole, so i had etch lines burned in where i need to drill the holes on the mill.

Ok, here’s some body shots…

Before:

After:

A few blow holes, nothing that won’t be taken care of with seam sealer, but all in all a good solid repair.

The last shot is a good comparison for everyone who thinks the shell is beat… See the rust at the bottom? That’s one day of surface rust on 100% new metal… The camera REALLY makes it apparent… It’s almost invisible to the naked eye… Same goes for a lot of the “rust” on the car…

that’s probably a good idea. have you considered rust inhibiting paint? :lol:

seriously, it is coming along great. i can’t wait to see it when it’s done.

trying to get it done for spring/carlisle/winged warriors… I’m busting my ass on it… we’ll see…