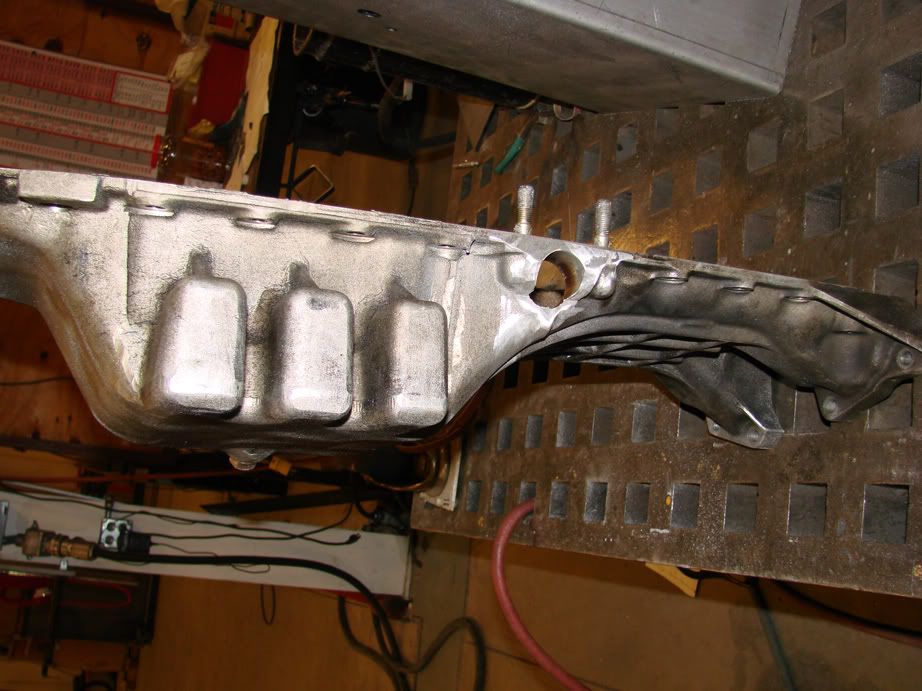

yeah, that’s what i’m looking at. though the hole that’s close to the lip (the hard one to weld) is also stepped. the plug would need to be installed from the inside, out.

…shouldnt make a difference in windage. :gotme:

You only need a good seal and similar expansion rates really.

Or am I missing something?

This one?

Not that its the best pic/description, but from what I see You could def tap that from the outside. Just carefully aligned.

yes, that’s it, but a tapered pipe plug won’t work there. Another problem: the hole is 1.25. The max root depth on a 1" NPT is 1.20 The next size up, 1 1/4 NPT uses a 1.5" hole, which is too large for that particular location.

I am looking into some sort of expandaple rubber plug… I don’t have enough wall thickness to be comfortable with a press fit aluminum plug not leaking

gotcha. yea, that size def limits You.

I dunno about a rubber baby buggy bumper though… hell, II part epoxy would be better then that, as far as heat cycling is concerned.

looks like a fun project…

:tspry:

Press in plug with 2 part epoxy would work well.

go to autozone or carquest or napa and get a freeze plug and use some jbweld

i think i am going to braze it. if not. i will make some new plugs that are a tighter, press fit and use epoxy. This probably requires me to hone the holes, though.

also, i will never use JB weld on anything. ever.

wow this is deff gunna be sick as hell i can’t wait to c it dirty told me about the project and it deff. badass :tup:

yeah, but the hole is already 1.25, so the minor diameter must be larger than that for the taper to engage. Also, I am not about to shell out the 300 dollars for the tap. LOL.

I think we are going to braze it.

Pffffft. baller my ass

-edit-

i suck at linking, tap = $67 , die = $56 f/ mcbastard

^^^ this dudes too smart for his own good.^^^lol. this project is gonna turn out amazing if you stick with it. cant wait to see it all done.

well, that’s alot cheaper than the machinist i asked (but they don’t order the shit anyway… bad source.) Regardless, it’s still too small.

it’s still too small.

That’s what she said!!! OHHHHHHHHHHHHH!!!

Um, I mean…

You could also use a flanged plug w/ gasket that was fastened from the outside. IE, plug is nearly the same dia. as what you have, with outter flange w/ mounting bolt holes, tapped in ze pan. Add gasket for her enjoyment. Viton or something would have no problem handling the oils/heat. But now we’re just making this more complex than it needs to be.

I would just bore the hole and order the appropriate sized plug (or machine it). Press it in, use sealant on the outside to prevent AIDS.

This project is awesome-tots

if you finish it and let me drive it i might let you butt-sex me.

more pics more pics