After all, rotaries is 40 years behind pistons.

there is a reason why 98% of cars are equipped with piston motors. not to say that the rotor motor has no potential.

there is alot of people making HUGE numbers with rotary motors.

how about you compare a rotary motor and a piston motor at 600, or even 700 hp and see who makes it to the highest km.

and as stated above there is alot of rotary motors goin with big km’s on a small basic tune, probably alot lighter then factory specs, in return you get a reliable motor with mid-range power.

there is also alot of piston motors running small tunes that will in return out perform a rotary motor.

but then again as stated im going on personal experience.

after all, we are a nissan/datsun club and we all know that no one here, if mabye one still has wankel engine in full operation

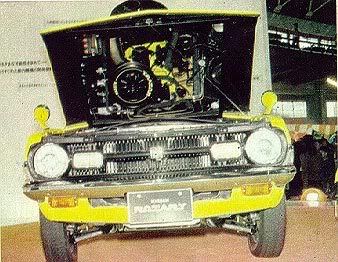

Nissan showed a prototype Wankel rotary engine at the Tokyo Motor Show in 1972, but it never reached production.

just look at the irons and rotors. pretty crazy, almost as mazda has it now. same basic setup alot on top waterpump top left.

other then that the mazda motor as two injectors and also twin spark plugs one primary and one secondary. oil filter in the same place as mazda.

too bad it only made production for a small period of time.

here is a few more pics. one of a Suzuki motorcycle that tried to use rotary

and here is the nissan kpb110 chassis code with a rotary motor still original

dual plugging was first invented in the 50’s as a detonation cure and can be found on 50’s porsche race cars for that purpose

Nissan did make a production rotary motor. It was only found in the first few production cars and quickly pulled. Please reread my first post. I mentioned it there. The S110 (1979-1983 Datsun 200SX)

That technology of dual spark plug was first found in Chrysler Hemi motors to try to completely burn the intake mixture before the exhaust stroke because it was being scavenged on the exhaust stroke. Porsche did not use that technology in their race cars till the near mid 70s. They had similar technology in one of their production cars by the mid 60s. One would think that dual plugging would completely burn the intake mixture, thus coming closer to the stoichiometric ratio and thus, having a hotter combustion and potentially detonation. Cure for detonation?? I don’t think so. Cure for complete combustion due to scavenging exhaust system. Yes.

Perhaps if (most of tnc) ppl would not take each and every thread off topic, instead add to it with knowledgeable responses, there would be less confusion?

Perhaps you didn’t read the title? Well if you missed it, here it is again in bold.

Rotary Engine vs. Piston Engine - Opinions?

I love the rotary, it’s light, small. The FB’s were awesome, I would love a 12A with a single webber carb. 220hp on a 2200 lb. chassis.

they may be less fuel efficient, but interestingly enough, a N/A rotary runs better on the lowest octane fuel you can find.

the renesis is an interesting design, the ports face the side of the rotor instead of the face, it eliminates scavanging improves fuel milage and emissions.

BTW, why the f*ck hasnt josh made a post?

Welcome back Terry. Good to know you’re still alive and not out O.D’d on weed and boozz somewhere with Pete :R

That’s what I was saying. I keep saying that I made this post for him but I haven’t seen him on this thread at all. He keeps badmouthing piston engines but obviously doesn’t have anything good to say about Rotaries either. Either that or he just doesn’t know anything about them.

Pretty much it. He thought he had 13B-RE in his FC…

fixed ![]()

He thought he had 13B-RE, and was boasting about a 13B-REW swap (which is near impossible due to different motor mount).

I corrected him saying that he had a 13BT, not a 13B-RE

man u guys know alot @_@

might as well add my 2cents:

RE > PE:

- smaller size in comparison to similar output PE engines (means less weight, and easier to achieve 50/50 balance

- high rev limit (for ppl with heavy feet, like me :))

- less parts to fix/rebuild (more simple?)

downside to RE’s:

- more vulnerable to lazyiness (as in, one needs to be more diligent with maintenece)

- really fricken loud without an exhaust

as for the rest of the cons stated by u guys, whenever you run a boosted application, you’re basically tossing reliability and miliage up in the air. if you’re so worried about reliability and miliage, dont run a FI setup

IIRC, RE’s by design start off with low power (torque?) and gain as they rev higher, leading to low bottom end, but wicked topend (tho i think FD’s correct this with sequential TT’s)

one of my dream projects would be a Suzuki Cappuccino with a Renesis swapped in and tuned to 300hp. think about it. a 1.3L engine putting 300 to the ground in a super light car. my S12 was 2.0L and only made 94Hp NEW.

ps. im suprise noone’s mentioned the 4 rotor builds. those are teh sex