Very nice :tup:

buahahahhaha

Where did you get the counter sink to sink the brackets for the rail?

ive got a couple sizes laying around from when i worked at cameron.

ok, finaly got all my exhaust componants in and let me tell you this 4in downpipe is turning into quite the task. Ill figure something out but everything will have to be precise so things dont come into contact.

i wanted to leave enough room to recirc waste up to my downpipe but ill have to put the hood on to measure clearance. hopefully ive got some room. if not ill just have to figure something else out. oh, and im out of argon.

Looking good man! Glad you got some work done besides telling us our cars will never run while not letting us go work on our cars hahaha.

dude, you shouldnt have bought exhuast, you might be able to buy my 4in cheap if this doesnt work.lol

If you want to sell it cheap let me know and I would maybe still take it.

lol, ill make it work, even if i have to buy a nova to put everything into. Just wont be as easy as i hoped. you should come gimme a hand.:walter:

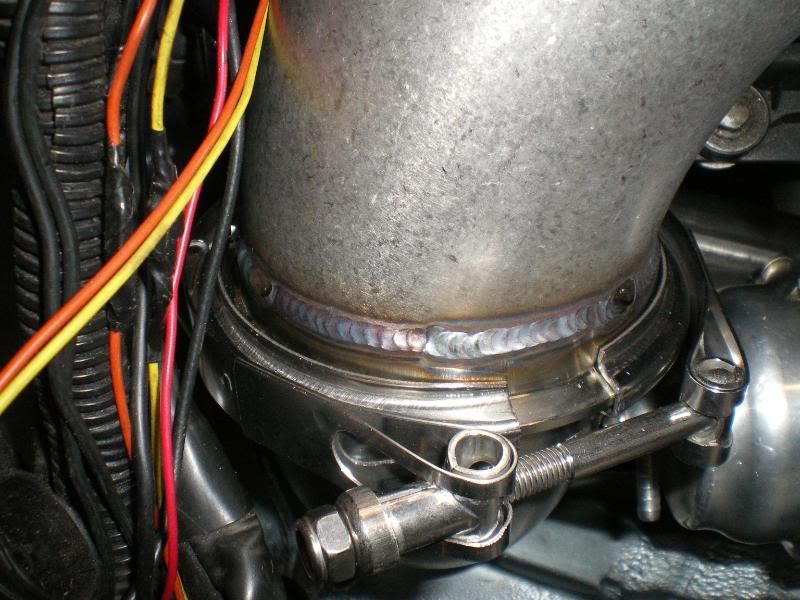

yup, downpipe is fully tig’d. some undercut in spots but oh well, i may make another pass to clean up some of the welds. something friggin shrunk on me because now my downpipe is touching my wastegate nut on top.:mad:

so ill just have to modify something somewhere else now so that clears.lol gotta love fabrication. sometime i wish i had the money to pay someone to do this crap.

Wow great job!

come help me put my hood on to see if everything clears.lol

I know you’re new to tig welding and all, but those welds look horrible.:gay3:

Nice job john!

those wires will be out of harms way right?

I think he is going to use heat resistant tape to hold them to the downpipe

That is a FAT pipe. Looks nice.

Lookin great. Good work.

Dan

got some goodies today.

and fixed the wastegate issue by shortening the waste gate runner.

and i may have to massage the shock tower a bit for some breathing room.lol

Man you have tons of room easily fit 3 maybe 4 pieces of paper in there.