GRAPE!

I like the purple drink! Make this a DONK please.

are you going to run the same head/cam combo on the built 3.0?

no more Root-beer , cant believe you  Make my spindalz purple?

Make my spindalz purple?

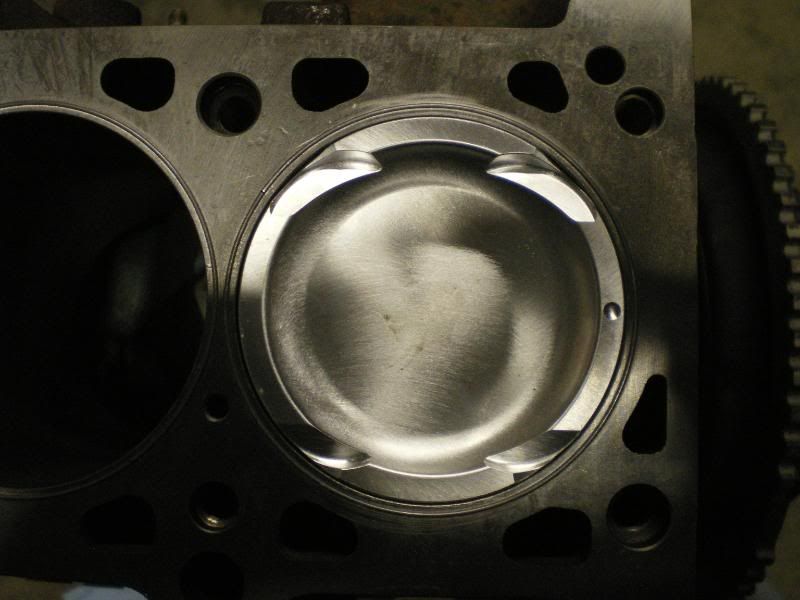

poor stock piston.  i am impressed with the build so far and the strength of the stock pistons.

i am impressed with the build so far and the strength of the stock pistons.

any idea on their composition and how much power they can take if all the external issues are handled (like the fuel rail)?

i assume you are using stronger stuff now but im still curious.

i read back in the beginning of the thread about hooking a knock sensor to the MS. did that ever happen?

Brian

Normally the stock pistons are the stronger part and the rods are the weak links. All of the stock motor High HP guys normally substitute alotta fuel with meth controllers and suck so they never had to deal with the problem i had when i was going for big power. Im sure stock pistons will hold 800whp but the rods on the other hand will not. the rods have held 800whp before but it was short lived.

I have the knocksense hooked up but not through the MS. Its just an adjustable LED right now. megasquirt will only let you use the knocksensor if its pulling timing when it sees knock above a certain threshold. I didnt like that and i would wrather have full control so i just use it as a tool now when tuning.

yeah the Knocksense isnt the most ideal setup as it doesnt take into account increased engine background noise as the RPM’s rise. Im working on a knock box that takes into account RPM noise increases and it samples really fast (like 2000 times a second) and will never miss a knock event. it will be a DIY deal. ill let you know how it works out after i fully test it. as long as the MS provides a pulse whenever an ignition event occurs (i think it does) my setup will work well for something like your setup.

yeah the rods look a little small for 800whp. pretty impressive stock stuff especially for N/A.

Brian

lol @ custom rod. good job as always john

well i hope the new build goes good. how did the butt joint exhaust clamps end up working for you anyway?

I dosn’t think Ive seen this thread before, very nice build. Those plates you added, are they for the front or rear (both?) subframes? the metal there gets bent or the rust though? did you weld them with overlapping tacks?

jon you always gotta live around the corner from me, if you need a slave to work on your car lmk!

Love that grape color, awesomness.

not very good for a forced inducted car. too much exhaust pressure blows them off so i always put a couple tack welds on it so they dont slip off.

thats the rear subframe area. The body sheet metal where the rear subframe bolts to is know for ripping/tearing out. Like i said i have yet to experience this so i figured i would just reinforce it with some metal plates just like bmw does from factory on m3’s.

well, i guess ill just start a short list for now since i have many unknowns so far.

Custom wiseco (ICS) 9.5:1 pistons.

135mm arrow connecting rods

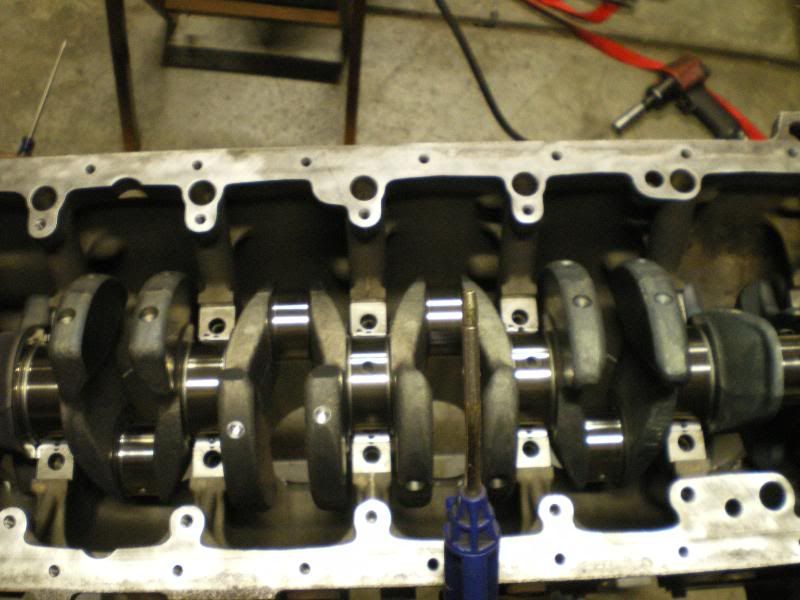

S52 crank stuffed into m52 block

acl rod bearings

kolbenschmidts main bearings

oringed block with matching reciever groove in head

custom t4 twin scroll turbo mani built by myself

custom 4in ss exhaust

etc etc ill have to add more as i remember but on to the pics.

custom oringed block.

reciever groove cut into the head to recieve the oring in block.

Its hard to see in the pics but the head and block are both resurfaced to a very smooth almost mirror finish which will be critical in head gasket sealing.

cleaning and making sure the piston squirters are still functioning correctly then reinstalling.

Crank all balanced and polishd and ready to go.

after cleaning all journals out with alcohol and wiping them all clean i reinstalled the bearings and lubed them with sta-lube moly since its probably gunna be a while before she breaths fire.

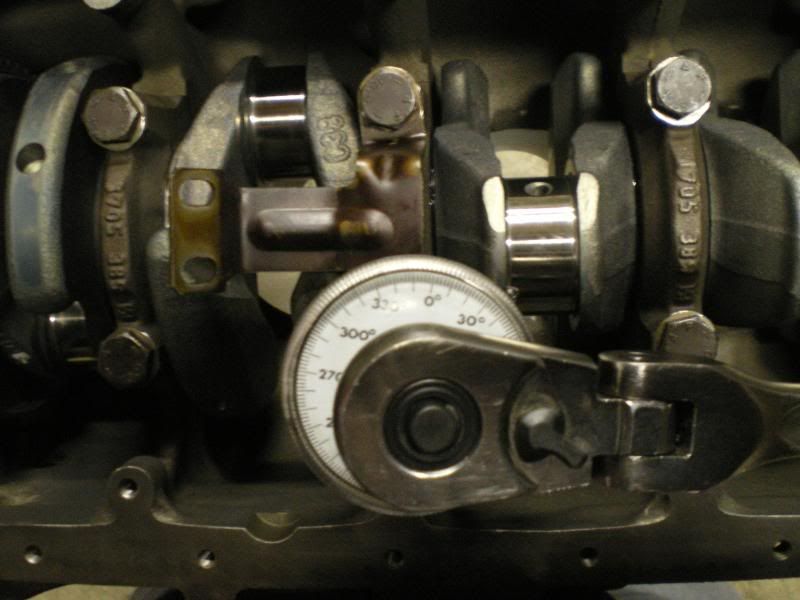

torqued up and ready to go.

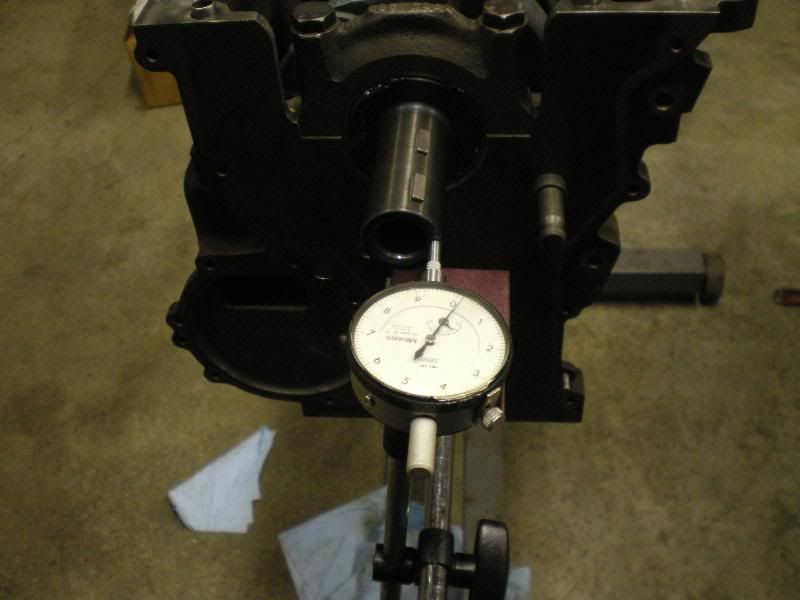

checking endplay

picture of the goods going in the motor.

picture of the arrow rod which weighs in at 501.2 grams.

Assembled the rods to the pistons and almost lost an spiral lock along with an eye in the process.lol

Here she is at home after i filed the rings to fit.

I should have the rest of teh shorty together today.

i like what im seeing.:tup:

Putting the holiday to good use :tup:

I thought you were going na this upcoming year?

unless i land a job anytime soon it will be one strong NA block.lol

Curious why O ring and receiver groove in the head? Is that something you wanted to do or what the machine shop recommended? No port on the head?

block is oringed because bmws have head gasket sealing issues after about 30psi. I wanted to oring it and the machine shop agreed it would be the best solution.

head will remain untouched with the s52 cams.